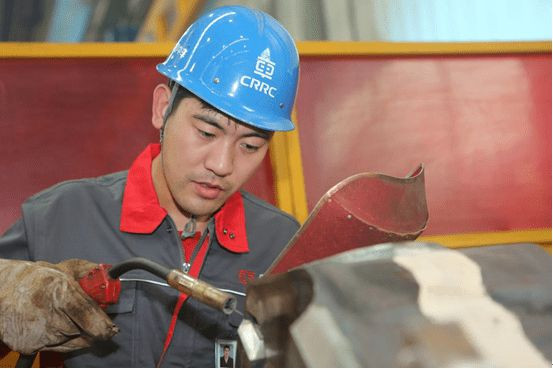

Artisan style | Zhang Gaofei: High -speed rail crafts

Author:Qilu.com Time:2022.08.19

Zhang Gaofei is a senior welding technician at the Step Fangfang Vehicle Co., Ltd.'s steering frame division. He joined the work in 2009, and he practiced his excellent skills and superb welding skills through unremitting efforts. He has been responsible for many times in the company's key projects. Essence

Diligence and hard work are the most basic homework for technical workers engaged in welding work. In order to master more superb welding skills, Zhang Gaofei does not miss any opportunities to exercise and learn. In the past few years, he has participated in the company's export of the company exported to Delhi, India's end. The process regulation and welding production work of key projects such as racks, SW-160 steering gear welding, exported to the Middle East internal combustion vehicle group, trailer architecture, and exported Italian high-speed rail welding welding. Human and material costs have created considerable economic benefits for the company.

The training at work has allowed Zhang Gaofei to accumulate rich practical experience. Every year, he actively participates in the company's skills contest organized by Qingdao, China CRRC and the SASAC and achieved excellent results. In 2014, he won the MAG welding award in the third "Jiak Cup" international skills competition hosted by the SASAC. In the same year, in the 13th Skills Competition of Qingdao, he won the championship of the Welders Skills Competition. He was awarded the title of "Qingdao Welders Worker Species" and "Qingdao Technical Expert". Essence

In recent years, Zhang Gaofei has actively put into outstanding contributions to the company's transformation and upgrading and innovation development of the company's transformation and upgrading, innovative development, and the spirit of innovation.

In 2013, by optimizing the welding process of the 206 framework, Zhang Gaofei invented the "Fixed Installation Method of the Pillow Hanging Seat" to improve the production efficiency by 130%, ensuring welding stability and product quality. In 2015, in the production of the Italian high -speed rail architecture project, he improved the welding position of the U -shaped welded welding, proposed the "welding torch protective cover" improvement plan, increased the welded depth of 4%, and increased the product pass rate by 30%; The solution of the technical difficulties of welding bottoming, single -sided welding double -sided molding "has increased the cross -welding rate of side beams and beam U -shaped seams from 36%to more than 98%; by optimizing the welding process, the side beam of the Italian high -speed rail framework project project is optimized. The adjustment time of welding deformation saves half, and consumables save more than 50%. The Indian Delhi steering gear "Beilou Raiders", which was designed and produced, made a company's annual production cost of more than 130,000 yuan, which improved the production efficiency of the beam by nearly 10 times. When producing in Beijing Metro Line 4, the problem of "single -sided welding double -sided molding" of the motor hanging seats that he solved, saving the manufacturing cost of nearly 190,000 yuan for the company. In 2018, the "steering rack auxiliary beam ring -shaped welding bite problem" was resolved in the small part of the "Fuxing" EMU welding work, which improved the qualification rate of product overpass and greatly reduced the labor intensity of employees. In 2019, the "welded robotic player" of the trial system successfully completed the first appraisal task of 250 kilometers and 350 kilometers of EMU steering frame beams and auxiliary beams, which was praised by the user's intersection.

Zhang Gaofei, who has many honors, is never proud of himself. As the leader of the company's "Zhang Gaofei Model Studio", he pays special attention to sharing work experience and personal experience to share with more skills and cultivate more young technicians. Over the years, he has trained more than 650 newly -operated welders for the company, with a total of 14 apprentices, of which 3 of the central enterprise technical experts, 4 of the company -level skills experts; 21 international welders training, accumulated accumulated Training 425 international welders.

Adhering to the core values of the CRRC, which is "good and good for goodness", Zhang Gaofei is brave and surpassed. The honorary titles such as youth positions of central enterprises have made their due contributions to the realm of high -speed rail craftsmen in the new era.

- END -

Precision service, adding concern, worrying, solving the development

On August 11, the two new automatic calf feeds in Zhejiang Ecological Ranch were installed. The workers were busy producing, and a car was lining up to load fresh milk. Seeing the busy and orderly sce

Hongrida IPO: Liabilities, inventory and accounts receivables three highs and many have been cancele

Hongrida's liabilities, inventory and accounts receivables are relatively high, a...