In this matter, China is really strict!

Author:Global Times Time:2022.09.08

In 2022, a recipe milk powder supply crisis swept the United States.

The cause was that 4 babies were sick of formulas suspected of being contaminated, and two of them died. After a certain rare but dangerous bacterial sample was detected in many plants involved in the factory involved, the US Food and Drug Administration (FDA) closed the factory, and the company involved announced on February 17 that several formulas recall several formula milk powder. This leads to "milk powder shortage" in the United States.

In recent years, my country has attached great importance to the quality and safety of infant formula milk powder, and establishes the world's most stringent regulatory system with "the most rigorous standards, the strictest supervision, the strictest punishment, and the most serious accountability."

This is because the baby formula milk powder is too special -its quality and safety is related to the health and life safety of infants and young children, but also related to the happiness of the family and the future of the nation.

It is also because of the "melamine incident" in 2008, which once severely hit the Chinese dairy industry. The entire industry has painful and painful, and it takes several years to rectify and improve. The word "quality" is regarded as a Guiyu, and the safety bottom line is built for infants and young children's formula milk powder.

The "Notice of the General Administration of Market Supervision on Food Safety Supervision and Smamon of the Market Supervision Department in 2021" released in May this year shows that in 2021, the qualification rate for the sampling inspection of infant formula milk powder in my country was 99.88%, and the qualification rate of special medical use formulas was 100%. It is the highest qualification rate among 34 random sample foods.

It can be seen that the "world's strictest" infant distribution supervision system created by my country with a "zero tolerance" attitude has achieved the safety level of "close to full score".

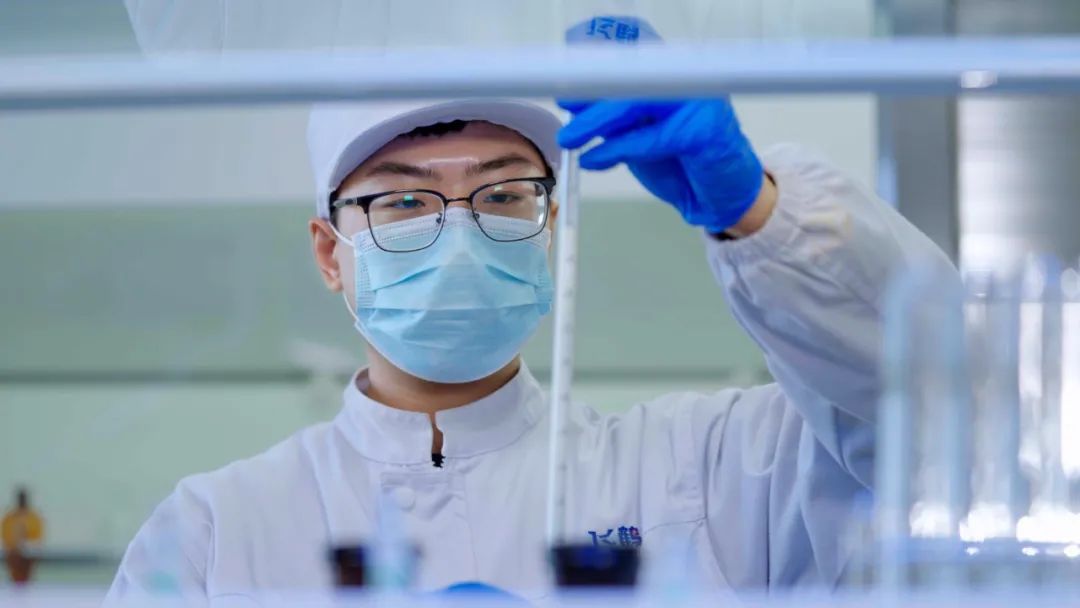

Feihe R & D Lab

Formulating registered high -level entry threshold

After 5 years of research, the new national standard of infant formulas in "the strictest in history" was released in March 2021. After the two -year transition period, it will be officially implemented in February 2023.

The new national standard highlights "more suitable for Chinese baby needs", and between the lines shows my country's control and guidance of the infant formula food industry. It also established a new "vane" for the second formula of infant formula milk powder companies -product research and development must be "tailored". The "body" here is the physique of Chinese babies.

With the continuous policy and system, it has been forcing enterprises to improve quality and safety guarantee capabilities, and China has not taken the usual way.

The quality is Guiyi. Between the formula filing system and registration system, we choose the latter in follow the "international fan" and the "more suitable".

For example, in terms of threshold settings. The United States "Federal Food, Drugs and Cosmetics Acts" stipulates that if producers who have obtained production permits need to launch new infant food products, they only need to submit an intent notice to the FDA 90 days before listing to describe the product to explain why the new is new to the new Production, marking formula ingredients and changes, explanation of the content of the processing process, etc.

In short, with the premise of production qualifications, the enterprise must "go to new" or "upgrade", and inform the competent department.

In 2016, my country ’s“ Administrative Measures for the Registration of Formula for Formula Milk Powder Products of Infant and Toddlers ”clearly stipulates that“ infant formula milk powder will be managed by reference to drug management ”. When the safety is safe, higher requirements are put on the company's research and development capabilities, production capacity, and inspection capabilities.

The policy landed, half of the miscellaneous cards were eliminated, and the phenomenon of "messy" phenomenon of infant milk powder brands in my country was changed.

With the implementation of the new national standard and the secondary formula registration, a new round of "knockout" will be opened. The retained brands are outstanding in R & D capabilities, excessive production capacity, and reliable detection capacity.

The technicians in the factory discuss the improvement of the tank

Comprehensive "physical examination" consolidation process supervision

During the fermentation of the American milk powder incident, there have been media reports that since 2020, due to the serious epidemic in the new coronary pneumonia, the FDA has canceled thousands of conventional factories inspections. From 2019 to July 2021.

In the inspection in July 2021, the FDA found that the factory had the problem of lax watering and sanitary procedures, but it did not issue a formal notice.

After shutting down the factory, the United States official said that the FDA knew that the suspension of the union exacerbated the milk powder supply crisis, "but we have no choice, because the sanitary conditions there are poor", "shocking" and "unacceptable."

The bitter fruits brought by the supervision, consumers in the United States are still "paying".

In recent years, China has established a comprehensive supervision and inspection system to effectively ensure that supervision is often online. Among them, the system inspection is a comprehensive "physical examination" of the production license conditions of the enterprise, the implementation of the food safety management system, and the inspection ability.

In 2014, the system inspection of all domestic baby milk powder production enterprises was launched. Within three years, all 108 domestic noodles -matching manufacturers were inspected.

This is a new round of big waves. According to incomplete statistics, as of July 2018, 19 companies have been ordered to suspend production and rectification, and production has been restored after rectification. Enterprises actively cancel the production license.

If the formula registration test is the ability of the enterprise, and the system inspection is to test the "conscience" of the enterprise. After this battle, the company that can still stay is both capable and able to adhere to the original intention.

The research institute conducts sample testing

Yueyue sampling inspection "export barrier"

In addition, another "global only" in my country's regulatory system is the "Moon and Month" sampling inspection system. In February 2016, the relevant departments further strengthened the supervision and sampling inspection of infant formula dairy, and changed from quarterly sampling inspection to "monthly random inspection, monthly public". If the random inspection is unqualified, it will be notified by the whole country. If there are two unqualified formulas within a year, the formal registration certificate will be revoked.

At present, my country ’s sampling inspection of infant powder has achieved“ double coverage ”, that is, full coverage of all regulations required projects, and full coverage of all infant powder enterprises. This to the greatest extent to prevent the increasing production and operation in the industry.

At the same time, information disclosure has gradually increased. Since 2015, the "negative list" will report in detail manufacturers, batches, indicators, indicators, excessive degree, processing methods, and attach reference standards and explanations.

Researcher conducts sample testing

The punishment for illegal and illegal enterprises is also continuously strengthened. In May 2021, a variety of imported brands (0--19 June) were detected by the detection of cottonin exceeding the standard, fined millions of yuan, and the highest was nearly 10 million.

The strictest supervision is the best safety level. Data show that from 2014 to 2021, the national sampling check rate of infant formula milk powder increased from 98.3%to 99.88%.

Enterprise increases: the air must be "tube"

Under the "strictest supervision" of the country, Chinese infant powder enterprises have also continued to increase quality and safety to build a safe bottom line.

Feihe Intelligent Chemical Factory, the robotic arm is loading

Take the flying crane as an example. As a leading enterprise in the industry, Feihe has always regarded the quality of quality of the enterprise. In the 60 -year development process, the quality management concept of "quality cannot be made for anything" has been formed. Establish an enterprise's quality control system.

"The quality control of milk powder is very complicated, involving various links, formulas, processes, and production of various raw materials. We are based on ISO9001 and FSSC22000. Quality management system. "Luo Huarong, senior director of Feihe Quality Management Department, introduced.

For example, in terms of microorganisms, Feihe borrowed from the practice of the pharmaceutical industry to manage the production environment with the "pharmaceutical -level" standard. "The microorganisms in the pharmaceutical industry have started early, and a mature and systematic management method and control system have been formed, especially the concept of prevention, which is worthy of our learning." Liu Yingtao, head of Feihe Center Lab, said.

Feihe factory employee operation processing process

In environmental management, the state usually only requires monitoring of lowering bacteria and float bacteria in the environment. "And we require the air to monitor all the compressed air and other gases in contact with the product." Li Nan, the factory of the factory, explained. Specifically, it is a high -efficiency air filtration system that effectively block various particles and bacteria with more than 0.5 microns.

For the detection of the Enterobacterium, generally guiding files use a regular method to judge whether the environment is polluted, but Feihe adopts a qualitative method to measure the production environment. This is strict in the industry that has never had environmental quality. standard.

"For example, the family decoration should detect formaldehyde. The quantitative method is to require that formaldehyde cannot exceed a certain standard value, but the use of a qualitative method is to request formaldehyde cannot be detected." Liu Yingtao explained.

Recently, at the Symposium on the New National Expert of Milk Powder Organized by Feihe, Jiang Shilong, the chief scientist, said, "Just like the national standard mentioned by various experts just now is the threshold, Feihe wants to" advance the threshold to the upper level ", with a higher standard standard standard, a higher standard standard. Ask yourself. "The path of quality of quality of Chinese infant milk powder, represented by Feihe, has never stopped.

Starting from the "strictest" new national standard and the "strictest" regulatory system in the world, the road of domestic milk powder upward is high.

- END -

Baoding Yixian: Fresh Tao Harvest Harvest Sale

Recently, more than 1,000 acres of fresh peaches in Beilunshan Village, Yishan, Yi...

A year -on -year increase of 8.7%!Zhoushan released the economic operation in the first half of the year

Zhejiang News Client reporter Zheng YuandanThe Zhoushan City Statistics Bureau rel...