"China's dominance in this field is increasing rather than weakening."

Author:Global Times Time:2022.09.10

Japan's "Nikkei Asia" magazine website published on September 9, entitled "China's dominance in manufacturing is increasing instead of weakening", the author is William Blaton. The full text is as follows:

When it comes to China's manufacturing capabilities, there are often disconnects between remarks and reality. Chinese manufacturers are losing the lack of substantial evidence such as the lack of substantial evidence such as the relatively competitiveness.

China's exports are still very strong. Not only that, the latest data from the United Nations Trade and Development Conference shows that the competitiveness of Chinese manufacturers has increased in recent years, not weakening.

For example, the growth rate of Chinese finished products far exceeds Germany, the United States, Japan and South Korea. From a data point of view, China is now more important than Germany, the United States, and Japan.

In addition, in contrast to the point of reducing the supply chain with China, Chinese manufacturers have consolidated their advantages in most industries in recent years. In fact, one of the most striking things in China's constantly adjusted trade structure is that it can obtain export share at the same time in low -tech and high -tech industries. Its export products include both leather products, trailers, and optical instruments.

On August 21, 2022, Beijing, the 2022 World Robot Conference was held. The conference exhibited a wonderful humanoid robot, with a lifelike expression. (Visual China)

This growth does not indicate the pressure of the industrial foundation, but highlights the competitiveness of Chinese manufacturers. These manufacturers are increasingly dominated by the manufacturing pattern of East and Southeast Asia.

This competitiveness is the result of complex and self -enhancement interaction between multiple factors, and a large part of which is the role of China's scale. This enables China to support domestic competition, innovation and professionalization, which is much higher than neighboring countries, thereby improving efficiency and reducing production costs. These are difficult for other countries to copy. This scale benefits were subsequently enlarged through positive industrial development policies, and this policy obviously has unprecedented scope and ambitions.

Therefore, it is necessary to comprehensively look at China's manufacturing advantages, especially based on the trend of any specific industry to conclude that it will be extremely misleading, no matter how attractive this conclusion is.

For example, China's rapid rise in wages attracts attention. However, if it is considered that this marks the loss of labor -intensive industrial competitiveness, it is wrong.

Instead, it reflects the significant improvement of productivity and a wider structural change in areas with higher levels of science and technology. In addition, the use of the national average salary level to measure the diversity of China's labor force.

This can be seen from the indisputable facts below: Chinese manufacturers' exports of low -tech and labor -intensive industries, including textiles, are still increasing. In other words, their innate advantages are extremely huge, and even overwhelming everything, so that higher labor costs themselves will not have a substantial impact on their competitiveness.

Therefore, despite the rumors that many people often mention, there is no real evidence that the factors that support China's competitiveness are reversing. On the contrary, the manufacturing industry in Asia will continue to focus on China, thereby further consolidating its position as the core of the regional economic system.

Source: Reference message

- END -

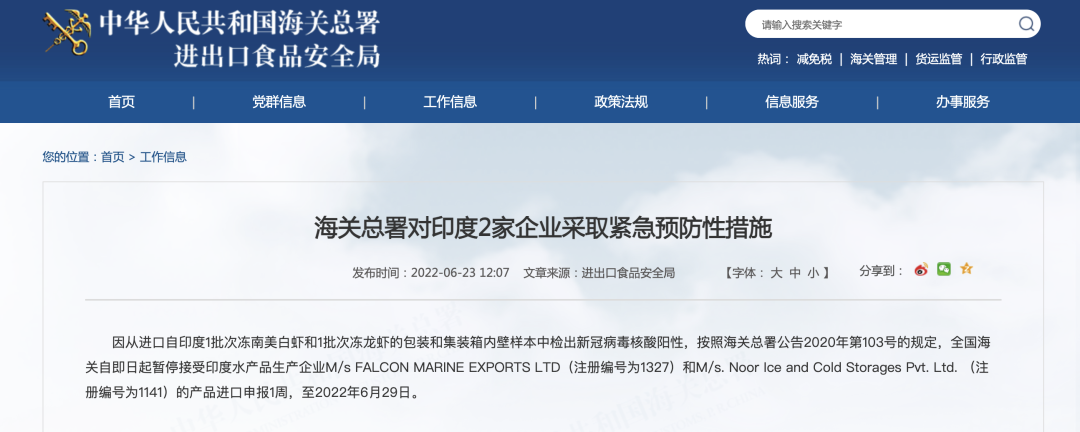

positive!positive!Positive ... emergency suspension

recentlyThe official website of the General Administration of Customs issued a num...

The contract area of the 5th Expo Enterprise Exhibition accounts for about 90% of the planned area

The reporter learned from the supply and demand docking of the Fifth Expo Technolo...