Listen to Zou Ping's development strong sound | Intelligent printing and dyeing technology empower to build a green textile production base

Author:Qilu.com Time:2022.09.20

Qilu.com · Lightning News, September 20th. On September 20th, "Listen to the development of strong sounds, feel the surging motivation -focus on the nine major projects, build a strong manufacturing city, and present the 20th National Congress" Hold.

The textile and clothing industry is the head of the people's "clothing, food, housing and transportation". In March of this year, Shandong included the modern light industry textile industry into the new and old kinetic energy conversion "top ten" industries, and this industry ushered in a new opportunity for high -quality development. At 9:00 am, the interview group came to Weqiao Special Printing and Dyeing Co., Ltd., Shandong. In order to meet the needs of the development situation of domestic and foreign markets, speed up shifts and production capacity upgrades, the company eliminates some backward equipment, increases some intelligent and efficient equipment, and enhances the company's mechanization, automation, digitalization, intelligence, and environmentally friendly green development level to create green intelligence Chemical textile production base.

In August of this year, the first production line of the wide green intelligent printing and dyeing project of Weqiao in Shandong achieved a trial production line. This project can be said to be an important part of the enterprise cultivating the intelligent matrix of the industry to cultivate "smart textiles, intelligent dyeing, smart clothing, and smart home textiles" in the integrated industry chain smart factory. The reporter learned that the total investment of the Green Intelligent Printing and Dyeing Factory of Weiqiao Special Large Printing and Dyeing Co., Ltd. has an investment of 25 million yuan. Among them, equipment and technical investment is 20 million yuan, 40 million yuan in infrastructure, and 10 million yuan in mobile funds. After the project is completed, it can form a production scale of 80 million meters of high -end printing and dyeing fabrics and 30 million meters of high -end printing fabrics. The company makes full use of the textile market and other favorable development opportunities. While accelerating the pace of technological transformation, it will increase technological reform and improve product technology innovation capabilities.

The project uses high -voltage electrostatic dust removal, photocatalytic dust removal of dust removal, and the expansion evaporator. It is more efficient and safer than traditional processing equipment. The digital printer does not need to be out of the Philipin version, the full color is imaging, the positioning is accurate, and the waste rate is zero. In order to achieve online testing of production, the flowmeter meter, counting table and weighing equipment used by all machines should have digital interfaces, and all control valves should also be transmitted by signal. Perform online collection of all devices and production processes, and realize the online information technology such as big data, cloud computing, the Internet of Things, AI intelligence, etc., to realize the online production process, production process, production order, production quality, production consumption, cost and production equipment online. Detection control, guiding production, guiding decision -making through big data analysis, opening data sharing in various aspects of production, truly realizing platform operations, paperless production office, and realizing scientific and technological empowerment.

Lightning reporter Chen Shuai Binzhou report

- END -

Bole City Xiaowei Industrial Park busy production guarantee supply

On August 18th, the employees of Yaoti Food Production Co., Ltd. were producing mo...

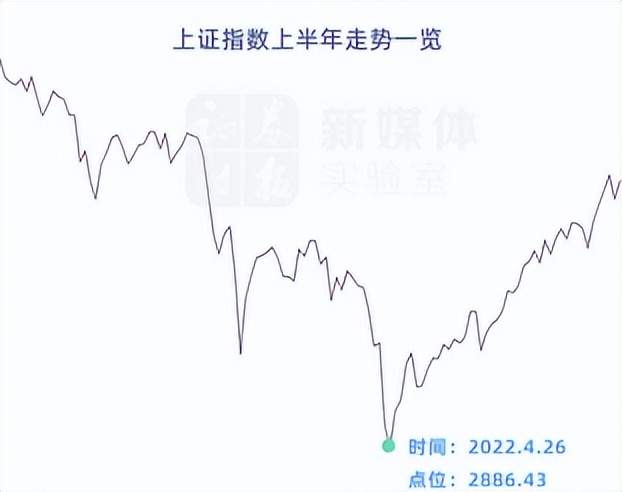

1102 stocks rose, and the coal sector was very strong ... In the first half of 2022, A -share events, come!

On July 1, today's broader market shock adjusted, and the GEM fingers led the decl...