The mystery of the "Centennial Old Store" was revealed today!

Author:Huangshi Daily Time:2022.09.26

A century -old company, long -lasting. In September, Xinhua News Agency, China Brand Construction Promotion Association, China Asset Evaluation Association and other units jointly released the "2022 Chinese Brand Value" evaluation information: 5 Huangshi enterprises including Dye Special Steel and Dye Monuada, the total brand value Nearly 40 billion yuan. Among them, the brand of Dalian Special Steel was worth 9.545 billion yuan, ranking 8th in the metallurgical color group.

Daeye Iron Mine

Dye Special Steel

Daeye Non -Colored

Huaxin Cement

The trip to the avenue is magnificent. In the journey of promoting high -quality development and accelerating the construction of the core cities of the Wuhan Metropolitan District, Daye Iron Mine, Daye Special Steel, Dye Metallurgical, and Huaxin Cement are inheriting a century -old glory and blooming youthful light.

There are factors of industrial development flowing in the blood, and the bones are engraved with deep marks of modern industrial civilization ... This is the pulse of the city of Huangshi.

3000 years ago, the mining and smelting of copper began here; more than 100 years ago, Governor Zhang Zhidong of Huguang founded the first heavy industrial joint enterprise in Chinese history, Han Yeping Ping Company.

Old site of Hanyan Ping Coal and Tie Factory Mine

The opening of large enterprises such as Daye Iron Mine, Daeye Iron and Steel Plant (now "Dae MCC Steel"), and Huaxin Cement, etc., the emerging industrial city of Huangshi has gradually emerged.

After the founding of the People's Republic of China, Huangshi started the process of industrialization and modernization. In Huangshi, the state has deployed 27 metallurgical, gone coal mines, including 27 metallurgical, machinery, building materials, and coal of key industrial projects or enterprises.

The long -lasting industrial civilization laid the solid home for Huang Shi. Dawan Special Steel, Daye Iron Mine, and Daye Non -Colored have been built into one of the top ten special steel companies in the country, one of the top ten iron ore companies, and one of the six major copper mines in the country. Huaxin Cement has become the three major cement production bases in the country Essence

The Dye Metallurgical Steel River section located on the banks of the Yangtze River

The highest peak period of the GDP of Huangshi excavation and its processing industry accounted for 62 % of the total GDP, and the overall economic strength is second only to Wuhan, becoming the second largest city in Hubei Province.

The rich mineral resources have continuously transported important raw materials for the country's construction of industrial production, and made great contributions. Huangshi also made the reputation of the "industrial granary" of New China.

The first day of Asia -Dawan Iron Mine Pit

From the establishment of the New China to the end of the last century, Huangshi provided the country with a total of nearly 200 million tons of iron ore, nearly 1 million tons of copper concentrate, and nearly 600 million tons of various non -metal mines.

Hundred years of vicissitudes, a finger wave. Since the reform and opening up, especially since the 18th National Congress of the Communist Party of China, Huang Shi has established 36 industrial categories, more than 4,000 products and nine major leading industries with its strong industrial foundation.

There are no backward industries, only backward companies. A century -old enterprise is based on its advantages, "picking the beam" and "singing the protagonist", strengthened technology research and development, product innovation, and continuously enhanced the core competitiveness of the enterprise.

This is the change of business model and realize the vivid practice of connotation development. Wugang Resources Group Daye Iron Mine Co., Ltd. (hereinafter referred to as "Daemei Iron Mine") promotes the intelligence of mining operations and builds a benchmark demonstration base for smart mines.

This is the change of competition transformation and the major achievements of the industry leader. Daye Special Steel Co., Ltd. (hereinafter referred to as "Daye Special Steel") has continuously enhanced its core competitiveness of the product, and 21 products fill the domestic gap.

This is the change of development concept, pursuing the highlights of green and low -carbon. Daean Nonferrous Metal Group Holdings Co., Ltd. (hereinafter referred to as "Daeye Nonferrous") launched the green renovation operation of the old smelting factory, and forged an advancement of "millions of production capacity" and "100 billion output value".

This is the change in the market structure, and the valuable experience in overseas markets. Huaxin Cement Co., Ltd. (hereinafter referred to as "Huaxin Cement") responded to the national "Belt and Road" initiative, continuously accelerated the internationalization process, and actively deployed overseas markets.

"Old trees have new branches, and innovation adds motivation. Each footprint witness the growth of enterprises." Speaking of the changes in the Daeye Iron Mine, Luo Yan, Minister of the Comprehensive Management Department of Daean Iron Mine, summarized seven "high light moments":

On September 15, 1958, Chairman Mao Zedong inspected the exposed mining line of the Dali iron smelting ore. This is the only mine that Chairman Mao inspected;

In the mid -to -late 1970s, the annual iron ore produced by the iron iron ore was 2.05 million tons of iron ore, becoming one of the top ten iron ores in the country;

After 2007, Daye Iron Mine successively established the first domestic iron mine museum and the first mining park in the country;

Around 2016, Daean Iron Mine -Mine -made positions cultivated the "Five Dynasties Models";

In 2018, Dae Iron Mine was selected as the first batch of Chinese industrial heritage protection list;

In 2019, Dae Iron Mine was selected as the first batch of green mines in China;

In 2021, China Baowu Iron and Steel Group Co., Ltd. was completed and put into operation at Dye Iron Mine.

Time whistling, rushing forward. Huangshi, an old industrial city born from mine and a factory, has a consistent feeling and ambition to plant industries.

Based on the traditional advantages of the old industrial cities, highlight the green transformation, implement intelligent transformation, and promote the transformation and upgrading of traditional industrial technical technological technological. In the new era, Huangshi unswervingly promoted the transformation and upgrading of old industrial cities with a new vitality and posture.

Focusing on the green transformation of the agglomeration, the construction of the national industrial transformation and upgrading demonstration zone is the starting point, establishing a sound energy consumption "dual control" and curbing the "two high" projects to blindly develop a long -term mechanism, and promote the pollution reduction and coordination of carbon reduction.

Focusing on the innovation and empowerment of gathering force, to create a national innovative city and build the Huangshi functional zone of the Optics Valley Corridor Corridor as the starting point, build a good use of Huangshi (Wuhan) offshore science and technology park, cultivate technology companies, introduce innovative talents Optimize innovative ecology. Focus on the upgrading of the agglomeration industry, increase the quality of the industry, transform and upgrade traditional industries, cultivate and strengthen strategic emerging industries, focus on building modern industrial clusters, and accelerate the establishment of advanced manufacturing bases in the country.

Focus on the development of the agglomeration region, use the advantages of Huangshi Linjiang, Lingang, Ling Air, and Linguang Valley, strengthen regional cooperation, promote the development of the whole region, and accelerate the construction of the core city of the Wuhan Metropolitan Circle and the central city group of the Yangtze River in the middle reaches of the Yangtze River.

Focus on the optimization of the agglomeration environment and deepen the "Thousands of Cadres into Thousands of Enterprises" activities. 338 service class "one -to -one" service 195 companies. The "Ten Ten Golds of Talents" was introduced, and the special funds of 10 million yuan were used for talent introduction.

Enterprises are the main body of innovation and entrepreneurship, and a vital army to promote innovation and creation. Huangshi ’s“ hard and hard ”environment is two -way, and the development of the industry has continued to improve the ecology, which has stimulated a wave of volatility and gave birth to a fertile soil.

Daye Special Steel Factory District

Dawe Special Steel was born in the late Qing Dynasty Hanye Ping Coal and Iron Factory Mining Co., Ltd. It was the first special steel factory after the founding of New China. It was once known as the "eldest son of the New China Special Steel". The first "Chinese Special Steel" was produced by producing the first furnace high -temperature alloy, the first high -temperature alloy seamless steel pipe, and the first submerged mirror tube blank.

However, at the end of the last century, Daye Special Steel was in trouble. After restructuring, import the modern enterprise management system, adhere to the development direction of special steel, and implement technological transformation. It has invested tens of billions of yuan to comprehensively upgrade the production lines such as special smelting and forging. Resource conditions continue to improve the core competitiveness of the product.

From the "Industrial Promotion" to the "Special Steel Power", Dae MCC Special Steel stepped out of the dilemma and entered the fast lane for development. , Japan, the European Union, and Southeast Asia, more than 60 countries and regions, and are widely used in key industries such as aerospace and other countries.

Daye Special Steel Production Line

According to the relevant person in charge of the Dafang Special Steel Planning and Development Department, the company has developed more than 200 new products annually, and the production capacity of special steel and the profit of tonna steel ranks among the top three in the country. In 2021, Daweng Special Steel cultivated 7 single championship products, and 21 products filled the domestic gap.

The technical reform is not rest, the investment is constantly, and the innovation is more than innovation. Today, Daye Special Steel has invested more than 1 billion yuan to build an integrated and coordinated intelligent chemical factory based on the industrial Internet platform. It invested more than 700 million yuan to eliminate backward production capacity and invested more than 2 billion yuan to build new environmental protection projects to promote green energy saving Production.

The technical reform is surging, and the innovative style comes. Huaxin Cement carried out the research and development and practice of solid waste technology in the coordinated disposal of cement kiln. The annual disposal of domestic waste in the six major disposal platforms accounts for more than 50%of the total industry in the country. Development model.

The Dae Iron Mine has successively completed 35 environmental governance projects such as the transformation of the old area, the selection of rainfall the rainfall, and the greening of industrial venues.

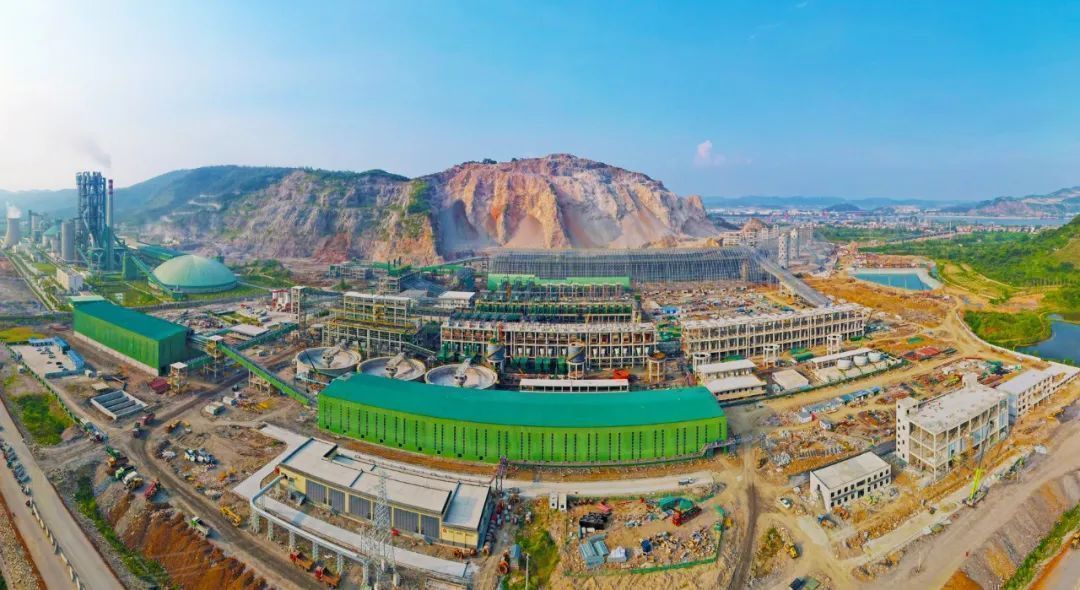

Dawan's Nonferrous Investment launched the green transformation operation of the Laoye Reining Factory. By continuously improving the clean production process, the purity of cathode copper was increased to more than 99.995%. In addition, it also invested 8 billion yuan to build a new smelter, and the development trend.

On September 16th, the sky was hot, and the Breeze of the Intelligent Management Center of the Daye Iron Mine was cool. In front of a large display screen, the staff was gathered to fuck the mouse, keyboard, buttons to monitor the entire process of mining, mineral selection, and smelting.

Daeye Iron Mine Intelligent Management Center

A auto repair factory that has been abandoned for many years has transformed into an intelligent management and control center, becoming a "less man, one -button, integrated control" intelligent demonstration base created by Wusteen Resources Group for the mining unit of Wusteen Steel Resources Group.

Xu Jiangdong, the head of the Smart Management Center, said: "This is an example of the transformation and development of Daean Iron Mine to maintain youthful vitality."

Dye Iron Mine is the raw material base of my country's modern industrial steel joint enterprise "Han Ye Ping Company". It has gone through the accumulation of ancient mining, the twists and turns of modern mining, and the humiliation of blood and tears of Japanese imperialism.

The freshman Daeye Iron Mine was rebuilt on July 1, 1958. It is the first large -scale iron mine company in New China. So far, the large -scale iron ore has excavated 153 million tons of iron ore.

As early as the 1970s, the large -scale scrapped stone field with a total amount of rocks was planted with a total amount of rocks, which formed the largest hard rock green reclamation ecological forest covering 3.97 million square meters of Asia, creating " The miracle of planting trees on the stone.

The glory that has not been waited, only the wonderful spelling!

Entering the new era, in order to solve the resource dilemma, after completing the territoriality registration of the legal person, the Dazhong Mine has become a four -level company under China Baowu Iron and Steel Group Co., Ltd. Thinking of the trend, business model, and development method, the road to green transformation and development of mineral resource conservation and comprehensive utilization has been explored.

Over the years, the pilot opportunities of the reform and control model of Baowu Group's resource mines are seized, and the corporate processes reconstruction and mechanism innovation have been promoted, and multiple unmanned and integrated control projects have been established. Dae Iron Mining Area

Data show that in 2021, the efficiency of Daean Iron Mine has increased by 8.8%, and the output of iron concentrates increased by 22.6%year -on -year. The recovery rates of copper concentrate and sulfur ore reached 84.15%and 71.23%, respectively. %.

The wind was surging, and it was necessary to break the waves. "Don't look at the market, just see if you are competitive." This is the words of Huang Shi's century -old old company.

On the afternoon of September 16th, in Dae Ye's 300,000 tons of cathode copper processing and clean production demonstration base, the electrolytic copper board workshop, the robotic arm was happily moved the electrolytic copper ...

Through technological transformation, labor productivity has been greatly improved. "In 40 years, the labor productivity of Daeye's non -color electrolytic copper plate has increased by 16 times," said Cheng Genong, deputy director of the workshop.

A set of data witness technical reform results: In 1982, the electrolytic traditional small board of the workshop was 200 tons of copper/person, 600 tons of copper/person in the traditional large board in 2000, and 3,200 tons of copper/person in the traditional large board cleaning production project in 2012.

Dae Metallurgical Monurable Switching Factory

In the Australian furnace central control room of the Metallurgical smelting workshop in Daemel, the staff on duty monitors production data in real time. "This is the world's largest Australian Matt furnace, which has been serving for more than ten years." Zhang Jinjun, secretary of the Party Committee and Chairman of Daeye Nonferrous Company, introduced that after three systematic technical reforms and upgrading, the Australian Matt furnace of the factory can not only be able to not only The feed "eats dry and squeeze", so that the amount of copper containing the slag is stable to below 1%, and the flue gas emissions are greatly reduced.

Zhao Xianglin, director of the smelting workshop smelting workshop, also tells such a story: At the beginning of the Australian Matt furnace, foreign experts asserted that the stove would be stopped for one month every year, and one month of maintenance caused direct and indirect losses of more than 50 million Yuan, extending "furnace life" is the key to smelting quality and efficiency. With the unremitting efforts of the technical team of the smelting plant, the use cycle of the furnace has increased from more than 200 days to 475 days, thereby increasing to 750 days today, and annually created more than 20 million yuan for enterprises.

A century -old company, youth is not old! Huangshi Industrial Heritage has witnessed the unusual development of China's modern industry, and has also inherited and promoted the immortal industrial spirit.

With the construction of the Huangshi Central Cultural District Project, the "Huaxin 1907" cultural park with the former site of Huaxin Cement's site as its core has shined, becoming a "net celebrity punch place". The old site of Huaxin Cement shows a new vitality, interpreting the mystery of the everlasting of Huaxin Cement's foundation, and showing the work style of "vigorous and passionate".

"Huaxin 1907" Cultural Park

Nowadays, Huaxin Cement has a global building materials group with more than 200 subsidiaries in more than 10 provinces and cities across the country and overseas, creating four major industrial bases in the world's most advanced building materials, new materials, environmental protection, and equipment. The 115 -year -old Huaxin Cement has exceeded 80 billion yuan in brand value, and is writing a song of youth of the "century -old rejuvenation" in the new era.

Run a new era and go to the future together. In the more magnificent journey, Dongchu's land to promote industrial transformation and upgrading, gathered a surging driving force to promote high -quality development!

Text: Bao Junhui Yimu Sheng Liang Jianyi

Picture: Ke Heng

Video: Jiang Bo Cao Yang Chun A Lei

Review: Yi Mu Sheng

Supervision: Bao Junhui

- END -

Henan's "Cold Chain Yujun" assembles the group to help the construction of a strong province of logistics

In order to implement the national 14th Five -Year Plan Cold Chain Logistics Devel...

The low -altitude economic momentum is ready to go to the future

Recently, in the upper reaches of the Yellow River and the important hub in North ...