Carbon monoxide feed raw materials?This technology won history first!

Author:Made in China Time:2022.07.21

Produced | NetEase News

Introduction: There are only 4-5 companies that can produce single-cell protein through gas fermentation worldwide. In 2021, the industry was called the "first year of single cell protein". Ethydrochties single -cell protein has obtained the first new product certificate in history. It is the first time in the world to achieve high -quality protein raw materials produced by large -scale production of inorganic substances under factory.

1. The world of ethanol canvy protein: from obscurity to "nothing but nothing"

With the increasing demand for resources around the world, the finding alternative protein raw materials has become an inevitable requirement for sustainable development of aquatic products and breeding industries. Replacement protein mainly includes botanical protein (soybean meal, cotton meal, etc.), animal protein (chicken powder, feather powder, blood powder, etc.), and single -cell protein (bacteria, yeast fungi, methane oxidation bacteria, microalgae, etc.).

Due to its advantages in productivity, protein content, and nutritional value, single cell protein has become a research hotspot of alternative protein. Single cell protein uses industrial wastewater, natural gas, agricultural and sideline processing products, and organic garbage as a medium to cultivate single -cell microorganisms such as algae, fungi or non -pathogenic bacteria, and then produced after fermentation, purification, drying, etc. Microbial protein.

Bacterial single -cell protein is an important aspect of single -cell protein research. Among them, ethanol canch bacteria not only have high nutritional value, but also balanced amino acid structures, and it is easy to digest animal digestion. Ethanol, which produces ethanol protein, is a variety of bacteria existing in nature. The genome sequence does not contain toxin genes and pathogenic genes.

Interestingly, carbon monoxide is toxic for humans, but it is food for ethanol stuffed. Ethalate can be used as a carbon source and ammonia water as a nitrogen source. After fermentation, oxidation, distillation, dehydration, separation of bacteria, spray drying, and sewage treatment, it obtains high -protein content protein.

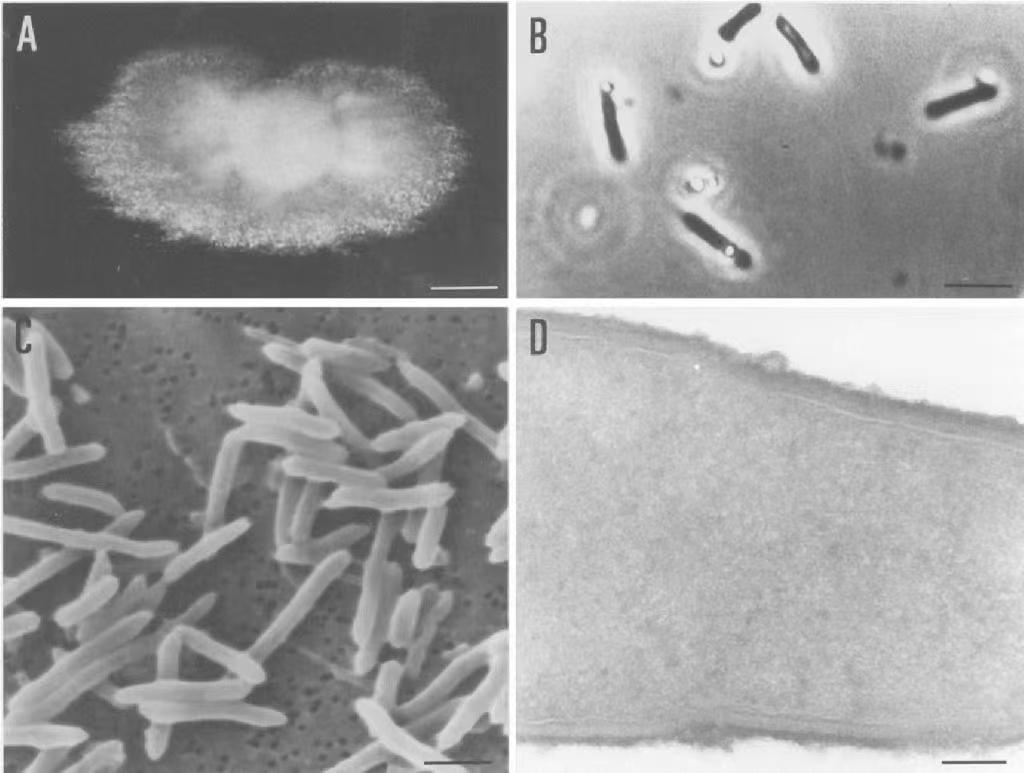

Micro Map of ethanol clustering

As early as the 1990s, asselia, such as ethanol stuffed, used a carbon gas as a carbon source to produce small molecular alcohol products. Subsequently, many countries began to study ethanol, but they still rarely paid attention to bacterial synthetic proteins. Focus on the study of single -cell protein, and also focuses on edible bacteria. In 2004, the protein of Polymidthococcal bacteria came out, but at that time, the global feed production was not so much, the price of fish powder was relatively low, and the cost did not have an advantage. Instead, the development of the entire single -cell protein was delayed. During the period of "Sixth Five -Year Plan" and "Seventy -Five" science and technology, China began to study the production technology of microbial bacteria protein. However, due to problems such as cost -effectiveness, efficiency, and safety, it has not been able to achieve industrialization. This has led to the long -term "obscurity" in the protein in the protein.

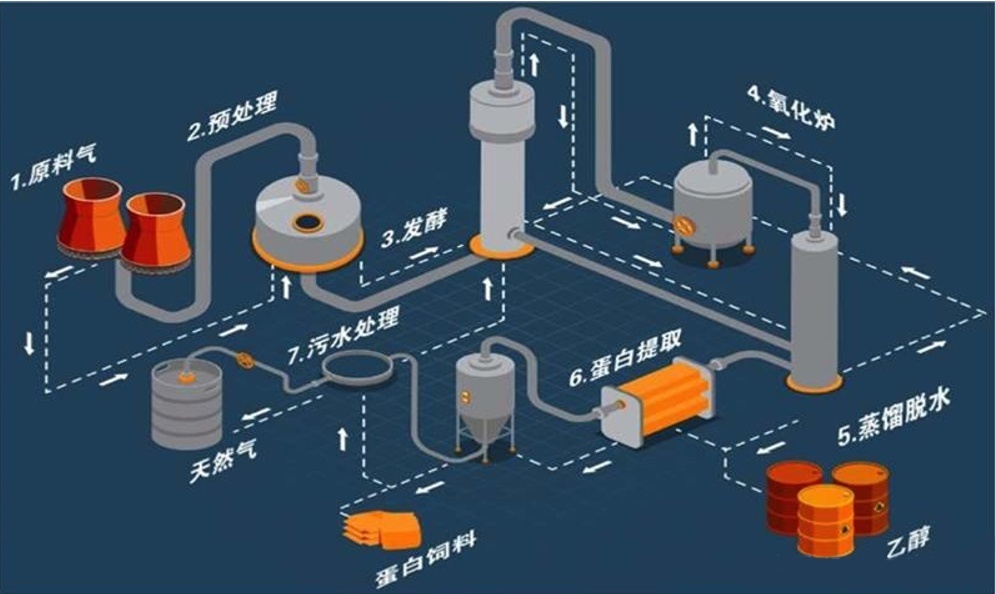

It was not until more than 20 years later that the protein of ethanol was found and used large -scale use and made a breakthrough in China. Ethalate protein process is the main raw material in the CO in ethanol sturobed bacteria as a fermented bacteria, CO in the steel industry gas (turntable gas, blast furnace gas), with ammonia water as nitrogen sources. , Iron acid sulfate and a small amount of vitamins (vitamin B1, vitamin B2, vitamin B5, vitamin B6, vitamin B12, tobaccoic acid, folic acid, and biotin), through gas pre -treatment, fermentation, distillation and dehydration, bacterial separation, spray dryness and spray dryness and spray dryness and spray dryness and spray dryness and spray dryness and spray dryness and spray dryness and spray dryness and spray dryness and spray dryness and spray dryness and spray dryness and spray dryness and spray dryness and spray dryness and spray dryness and spray dryness and spray dryness and spray and spray and spray and spray and spray and spray. Semoval treatment of 6 processes, finally obtained clean energy and bacterial protein such as ethanol. This process realizes the transformation of inorganic substances to organic matter. The "out of the same way" manufacture new type of feed protein resource ethanol clutch bacteria and converts the inorganic nitrogen and carbon into organic nitrogen and carbon. Completely independent intellectual property rights.

Second, synthetic protein quality production+application: layer by layer to ensure safety

It is worth noting that the protein that is synthetic is not eaten by people, but is similar to soybeans for feed. So, is it used for feed safety?

In fact, the safety of feed is under the control of the National Feed Review Committee. Mainly reviewing from 4 aspects: safety, effectiveness, controlled quality and no negative impact on the environment. The committee has concentrated more than 100 outstanding experts in eight fields including animal nutrition, toxicology, hygiene, and quality standards, which are both authoritative and rigorous. Laboratory equipment, personnel, and qualifications related to evaluation agencies are also guaranteed. The main basis of the Ministry of Agriculture and Rural Affairs based on the results of the National Feed Review Commission decided whether to issue a new product certificate and issue an announcement of the Ministry of Agriculture and Rural Ministry.

After in -depth demonstration, on August 29, 2021, Ethalene Bacarbin protein obtained the first new feed raw material certificate issued by the Ministry of Agriculture and Rural Ministry.

On October 30, 2021, the Institute of Feed of the Chinese Academy of Agricultural Sciences and Beijing Shougang Langze Technology Co., Ltd. jointly released major news: After years of research, my country took the lead in breaking the use of carbon monoxide to produce protein under the conditions of factoryization, and it has formed 10,000,000 Ton -level industrial production capacity.

Distillation and dehydration segment

Fermentation section

3. New breakthroughs in domestic technology: significance, in the future, it is expected

1. Let China stand at the forefront of the practice of life science

After our improvement, the growth rate of the "PLUS version" of the ethanol sturgeon has accelerated. How fast is it? Relying on the fermented ethanol closer after the improved, the time for fermentation of the ethanol is very short. It only takes 22 seconds from carbon monoxide to protein. The efficiency is more than 700,000 times the soybean. In the next step, the world record with a maximum of 85%of biomedic proteins. The breakthrough of this technology has greatly promoted the progress of global life sciences. 2. It is expected to break the dependence on the import of foreign feed

The annual consumption of my country's feed is about 450 million tons, and the source of high -quality protein is also extremely lacking, and it has to be imported a lot. In 2020, my country's soybean imports exceeded 100 million tons, of which the feed consumption was 88 million tons, accounting for 85%. The greatest significance of the project lies in "not competing with others, not fighting with food" to solve the problem of shortage of feed protein. In terms of industrialized production of 10 million tons of ethanol paracet bacteria (83%of protein content), it is equivalent to 28 million tons of imported soybean (30%protein content). This breaks through the space -time restrictions of natural protein plant synthesis, in order to make up for the largest shortcomings of my country's agriculture, the excessive excessive dependency of feed protein provides the weapon of the country.

Ethydramacacacchide

3. It will be contributed to carbon neutral and targets

This technology has opened up a new way to produce high -quality feed protein in low -cost non -traditional animals and plant resources. For each production of 1 ton of protein, 250 million tons of carbon dioxide can be reduced (the total production of ethanol and protein), saving 1 billion acres of cultivated land (an average of acres of average acres 300 pounds of soybean). In addition, the first -generation technology uses carbon dioxid ammonia water to generate ethanol and protein by fermentation of ethanol, and fixes 1/3 of carbon, which will still release some carbon dioxide. The second -generation technology that is currently studying uses carbon dioxide, carbon dioxide, and hydrogen ammonia to synthesize ethanol and protein, which can achieve 100%curing of carbon, no carbon dioxide emissions, which is even more significant.

4. It will be beneficial to waste use and recycling

There are many raw materials available for this technology, such as steel, electric stone, iron alloy, petrochemical refining, coal chemical industry and other industrial exhaust. Taking steel as an example, my country's annual steel output is 1 billion tons, and the carbon -containing turntable gas+blast furnace gas exceeds 1 trillion cubic meters. Although it cannot be achieved by 100%, the utilization part is also a considerable capacity. The technology is strong and has the basic conditions of large -scale industrialization. The "Fourteenth Five -Year Plan" Industrial Green Development Plan proposes to strengthen the basic research of industrial basic research and cutting -edge technology, and carry out new types of pollutant treatment technology and equipment basic research on carbon monoxide fermentation alcohol. The "Fourteenth Five -Year Plan" raw material industry development plan proposes to actively implement energy -saving and low -carbon operations, and the petrochemical industry has promoted low -carbon technology such as carbon monoxide qi -containing gaseous biological fermentation system.

Conclusion:

There are carbon dioxide synthetic starch in the front, today there are carbon monoxide and nitrogen synthesis proteins! China is steadily entering the rhythm of the science and technology explosion. At present, the approved animals approved by ethanol canopyl are fish, and the next step will be expanded. Although the overall volume of ethanol canch bacteria does not reach the level of soybean soybean, it can solve the problem of fishmeal dependence. At least we have the use of a carbon gas to produce bacterial protein, which is a "out of nothing", and the future development breakthrough will also have endless possibilities.

references:

1. Huang Zhewen, major breakthrough! Carbon monoxide "transformed" for 22 seconds is protein, Workers Daily, November 2, 2021

2. Cui Li, how does the industrial tail turn into feed protein? ——The story behind Etherbal Furer protein production, Farmers Daily, March 1, 2022

3. Ruan Xin et al., The research progress of ethanol protein in the breeding industry, China Animal Husbandry, 2022, No. 8

NetEase's "The Great Chinese Manufacturing" column original content, infringement must be investigated

The "Made in China" column invites industry authority and senior players to present the path of Chinese innovation in their eyes.

Cooperative mailbox: [email protected]

- END -

Igame G-One Plus is officially released, PC computer future evolution form?

At 8 pm on June 17, the Seven Rainbow held a new online product launch conference ...

Live Trailer | "Civil Aviation Wisdom" fifth cloud network integration to empower the digital construction of civil aviation

On June 30, the fifth online meeting of Civil Aviation Wisdom will meet you. This ...