See the high point of the future development system ⑤: Forging war eagle "China Heart"

Author:Hebei Radio and Television Sta Time:2022.07.28

The results of major scientific and technological innovation are the weapons of the country and the weapon of the country, and must be firmly held in their own hands. Hebei Provincial Renewable High -temperature alloy Technology Innovation Center, adheres to independent innovation, breaks through key technologies, and successfully realizes the high -temperature alloy materials of aviation engines in China. The series reports "Stealing the Heights of Future Development", which was broadcast today: forging the war eagle "China Heart".

The client reported on the client to help China dream of dreams. From the "flying shark" to the clouds, to the clouds, to the "Weilong" shining, guarding the four seas, a domestic war eagle pillow is treated, and the motherland is safe.

Zhang Anyi, a reporter from Hebei Radio and TV Station:

The plane soared, inseparable from the strong heart of the aviation engine. The key to affecting the performance and life of aviation is the materials that make it-high-temperature alloy. It can be said that the quality of these dazzling metals in front of you directly determines the performance of domestic fighters and the direction of hunting.

To meet the ultimate performance requirements, high temperature alloys need to tolerate the service temperature of more than 600 degrees and resist super high deformation pressure. At the same time, more than 20 types of elements and more than 100 production models have allowed the R & D and manufacturing of high -temperature alloys to become a concentrated representative of a country's comprehensive industrial strength.

However, the late start and poor equipment have allowed my country's high -temperature alloy industry to "run along the way". The key materials for fighter airports rely on imports for a long time.

Liu Meng, R & D engineer of Hebei Provincial Renewable High -temperature Alloy Technology Innovation Center:

The development of modern fighters is a generation of materials and generations of equipment. The development of materials is lagging, which seriously affects the renewal of aviation engines.

Reshape the material of the great power and forge the "Chinese heart" of the war eagle. The Hebei Provincial Renewable High -temperature Alloy Technology Innovation Center is guided by major national strategic needs and began to launch a total attack on high -temperature alloy industrialized production. But the "purity" of the material has become the biggest obstacle in front of them.

Zhang Huanhuan, R & D Engineer of Renewal High -temperature Alloy Technology Innovation Center of Hebei Province:

Previously, my country used ore smelting smelting, which was to extract element alloy smelting in the ore. In this way, there were many impurities and low purification, which is equivalent to a pure water level abroad, and the purity of our country is still at the level of tap water.

If the original craftsmanship does not meet the standard, it will come out of a new way. The researchers at the Hebei Provincial Renewable High -temperature Alloy Technology Innovation Center will cast their sights on the backing of the high -temperature alloy that was originally directly abandoned.

Zheng Qinfeng, chief craftsman of Hebei Provincial Renewable High -temperature Alloy Technology Innovation Center:

The material rate of high -temperature alloy parts in the process of production and manufacturing is very low, which will generate a large amount of returning materials. After the surface of the return material is cleaned, the internal quality is very good, and it is better than the configuration of new materials.

From scratch, gradually explore. Small to reagent formula, sound wave frequency, large to the number of device layout tables and process arrangement combinations. Fifteen years of research and development, once the butterfly changed. They produced China's first one and the only high -temperature alloy returned washing line so far, so that the high -temperature alloy "purity" problem has achieved a major breakthrough.

Zhang Anyi, a reporter from Hebei Radio and TV Station:

After this gate, the return of high temperature alloys is completing gorgeous transformation. Aiming at the future, in this hundred acres of factory area I am, scientific researchers are breaking through the final level of high -temperature alloy industrialized production, allowing domestic aircraft to have a "Chinese heart".

The development of materials has entered a new stage, and new problems have followed. The first thing that is the "dilemma": the melting is difficult and the molding is difficult.

Li Xugang, R & D engineer of Renewal High -temperature Alloy Technology Innovation Center of Hebei Province:

During the smelting process, the high purity of the high purity cannot be affected. This is the difficulty of melting; after the melting, it needs to be within 300 seconds. It is also a big problem.

Back to the origin. The production and use of high -temperature alloys is a symphony of a competition between metal and air. Only the aggregation is orderly to play a gorgeous movement of industrial applications. Starting from this idea, scientific researchers optimize the smelting process and create vacuum trieks technical blocking air to enter, so that the purity of steel ingots can be controlled throughout the process; enhanced forging types, and more than thirty process processes are seamlessly connected to ensure the fast molding of alloy materials, and high performance.

Wang Shouming, director of Hebei Province Renewal High -temperature Alloy Technology Innovation Center:

From 1mm to 500mm, we break through the manufacturing barriers of full -section high -temperature alloys. There are more than 100 varieties that can be produced, covering all categories of high -temperature alloy, which is at a leading level in China.

Make up shortcomings and innovate. Now, Hebei Province has mastered a series of key technologies used by high -temperature alloy returned materials. It has the ability to produce high -temperature alloy materials for production of aviation engines, which has opened the market developed by my country's aviation engines.

Sun Haitao, R & D engineer of Hebei Provincial Renewable High -temperature Alloy Technology Innovation Center:

Our high -temperature alloy has been applied to the main domestic fighter to help the dream of aerospace power in the new era.

Based on Hebei. Today, Hebei Provincial Renewable High -temperature Alloy Technology Innovation Center is combining technological advantages with the industrial and resource advantages of our province to create two major bases for the development and manufacturing of high -temperature alloy waste regeneration and high -temperature alloy materials, making Hebei an important production of key strategic materials for national national base.

Right now, they are still promoting the in -depth integration of innovation results with the industrial chain, and the goal of "promoting industry -university, research and use integration, concentrated force to overcome a batch of card neck technology" proposed by the Tenth Plenary Session of the Provincial Party Committee as a guide. The barrier continues to launch charge to seize the high point of future development.

Wang Shouming, director of Hebei Province Renewal High -temperature Alloy Technology Innovation Center:

Inheritance of the glorious mission of "material promoting the country", we will make full use of industrial development opportunities, aim at the international high -end, grasp the construction of innovation platforms, continue to increase the intensity of scientific research input, realize the full replacement of product imports, help innovative Hebei construction, to realize China to achieve China The great rejuvenation of the nation contributes.

Ji Shi Nu:

From the nine days, the Beidou shone, to the eagle hit the long air combat eagle; from the vast earth mine, to the storage of heavy countries to stand in the sea, green electricity entered low carbon growth. A series of vivid practices of Hebei Science and Technology Innovation Platform set a benchmark for us.

The Second Plenary Session of the Tenth Provincial Party Committee made new arrangements for strengthening scientific and technological innovation and promoting the strategic transformation of the industrial structure of Hebei. To implement the spirit of the provincial party committee, we must emancipate our minds, strive for enterprising, and establish and improve the mechanism for the assessment of science and technology input. We must implement the inclusive policies such as R & D expenses plus deduction. Concentrate to build a group of scientific and technological leading companies, specialize in specialty new small giants, science and technology small and medium -sized enterprises, and create more invisible championships. The opportunity is in front of you, you must seize it firmly! All localities should improve policies, innovate ideas, improve investment in the whole society in multiple channels, roll up their sleeves and work, and fill in the transcript by themselves.

Source: Hebei Radio and Television Station Jishi Client

- END -

Lighting to the world to send an innovation and entrepreneurship to recruit virtues to promote the integration and development of the innovation chain and the industrial chain

On July 5th, the Eighth Global Shenzhen Business Conference and Guangming Science ...

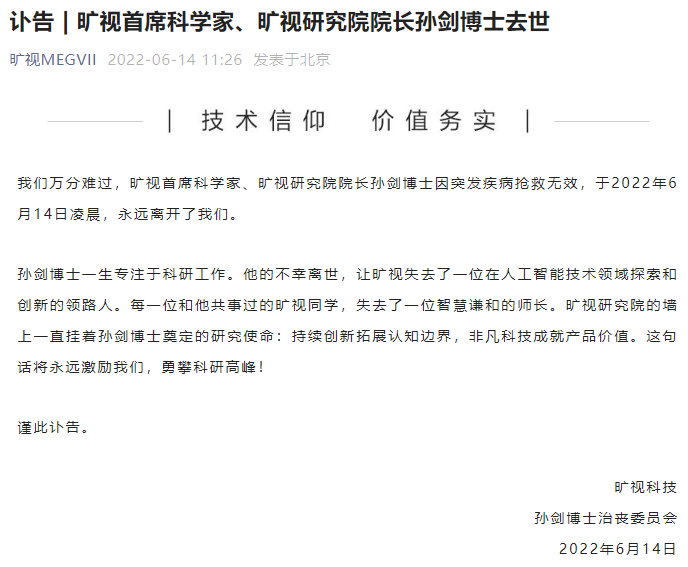

Dr. Sun Jian, chief scientist and well -known AI scholar, died

[Dahecai Cube News] On June 14, Kuangxin Technology issued a cricket, and Dr. Sun ...