Help "double carbon" recycled down products coming!

Author:Consumer Daily Time:2022.06.23

In April of this year, the National Development and Reform Commission, the Ministry of Commerce, and the Ministry of Industry and Information Technology jointly issued the "Implementation Opinions on Accelerating the Utilization of Waste Textiles", which aims to further accelerate the use of the recycling of waste textiles, build a resource circulating industrial system and waste The material cycle utilization system improves the efficiency of resource utilization. In fact, the down industry has begun. The reporter learned from the China down Industry Association that my country's "Regulations on the Management of Repairing Poon Feather and Products" is being formulated. At the same time, the association also revealed that at the annual meeting of the 2022 International down feather bureau held recently, regenerative down became the theme of the conference. one.

The Annual Meeting of the International down Feather Bureau focuses on regenerating down

Related standards are being formulated

In early June, the annual meeting of the 2022 International down Feather Bureau (IDFB) was held. This annual meeting adopted a combination of online and offline. It is reported that recycled down feathers are the focus of the meeting. Yao Xiaoman, vice chairman of IDFB and chairman of the China down Industry Association, said that down the meeting is the best warm material in nature. The characteristics of persistence. From the perspective of sustainable development, recycled down is a very good resource, and it is also a supplement to the supply of native down. It should be promoted and propagated.

At this annual meeting, the China Deep Industry Association stated that the "Regulations on the Management of Rebellion Poon Feather and Products" is actively formulating. It is reported that the traceability of recycled down and products will be carried out through the global down traceability system, and the sources of goods, circulation process, production loss and quality of the goods involved in the disassembly of old materials, recycled down water, recycled down procurement, product processing and brand sales are The level of information is approved to ensure that the source is clear, the whole process can be chased, and true and safe.

In addition, representatives of the Japanese Badminton Association said at the annual meeting that the definition and label standards of recycled down feathers will be formulated. In fact, renovation of old down is common in the Japanese market. It is understood that in order to effectively use feathers in the combination of Japanese feather products, consumers can rest assured to renovate and use feather bedding. The feather bedding reconstruction system has been established to distribute the "transformation label" to the transformation plant that meets the certification standards. It takes 10-20 days to remove the old and new, and it will decide whether to wash it with water or steam according to the old quilt situation.

10 million old down jackets per year are abandoned

Regenerative down applications are high and environmentally friendly

Regenerative down feather products represent a development direction of the industry. According to data from the National Bureau of Statistics, in the past five years, my country's down clothing output has exceeded 860 million pieces. In 2021, down jacket production increased by 3.51%year -on -year. As the down jacket gradually changes from a single heating function to taking into account both fashion functions, the update of down jackets has also accelerated year by year. 10 million old down jackets will be abandoned each year, of which about 1,000 tons of down raw materials are about 1,000 tons. Therefore, the recycling of waste down jackets has received widespread attention in the industry and the consumer goods market.

So, what exactly is regenerating down feathers? What is the status quo of the regenerative down feather industry?

In fact, for consumers who have been renovated with old down jackets or down, regeneration down is no stranger. These refurbished products use regenerative down raw materials.

According to the information provided by the China down Industry Association, down is a natural animal protein fiber, green and environmentally friendly, has the characteristics of multiple washing, high temperature resistance, etc., which provides the basis for the use of down regeneration. Therefore, the down removed from the old clothes is washing and processing again, high temperature dried, disinfected and sterilized, and still maintains the characteristics of fluffy and warm, with high application value.

It is also worthy of emphasizing that the production of regenerative down can save energy and reduce pollution compared with native down. According to the research and analysis of the Fifth Research Institute of the Ministry of Industry and Information Technology, the production and processing of 1kg regeneration down reduces the energy consumption of 1140mJ than the native down, reducing the amount of carbon dioxide volume emissions of 188kg. At the same time, it can reduce sulfur dioxide and phosphate emissions. Environmental impact of light chemical smoke.

"Old down jacket renovation" service is common

The regeneration down industry has begun to take shape

What is the market situation of regenerating down products? Search for "old down jacket renovation" on an e -commerce platform, and you can find many merchants who provide refurbishment services. There are those who can renovate a down quilt, some can be renovated into new styles of clothing, and even special "clothing shells" for sale: After the disinfection of the removed down ingredients is filled in the "shell" that has been made after disinfection and other procedures, and then suture can be sutured. At the same time, the merchant also showed the recycling process videos. After receiving the down product that received the customer mail, the first step was disassembled and collected, and the second step was to make centrifuge in the centrifugal machine. The third step was ultraviolet rays. Live oxygen sterilization, restoration of fluffy, fourth step, fully automatic machine filling.

It can be seen that in the Chinese market, some companies engaged in old down jackets and fluffy business have emerged. Some companies have begun to systematically study regenerative down products and form an industrial scale.

During the earlier "Old Clothing Zero Dispelling" activity, Guo Hong, assistant general manager of Shanghai Donglong Textile Technology Group Co., Ltd., said that down jackets have gradually become more fashionable from the initial warmth function, updating acceleration, elimination rate Very high, so it is of great significance as a down raw material recycling. According to reports, Shanghai Donglong Group has participated in the pilot work of the "recycling of down products" since 2018. At present, the first domestic GRS certified recycled down production line has been established. The down jacket disassembling equipment and completed the research and development of the old down sorting, disinfection, cleaning, removing miscellaneous technology. These regenerative down production lines can ensure the disassembly process of the down jacket used by customers, which meets the international labor criteria and disassembled disassembly. The down of the down is fully complied with the corresponding quality standards after professional processing, and the disassembly of the disassembly can be reused, and it can truly "abandon the old clothes." The production line can realize the automatic production of recycled down, and the annual output of recycled down can reach 400 tons. Active attempt to guide the "double carbon" target

China down Industry Association: Give play to the role of industrial guidance

The concept of circular economy globally is becoming increasingly rooted in the hearts of the people, and more and more brands and consumers have paid strong attention to environmental protection. In our country, in December 2018, the China Textile Industry Federation Environmental Assets Commission and the World Natural Foundation (WWF) jointly launched the "old clothing zero abandonment" action plan for the use of down the down textiles, actively promoting green design concepts, promoting green green Consumption models advocate green lifestyle.

According to the data released by China's Waste Textile Regeneration Technology Progress, the data released this year shows that the annual waste textiles produced in my country reached 20 million tons. Although there are relevant policies, the industrial chain of waste textile recovery, sorting, demolition, and processing has been initially formed, but the regeneration rate of waste textiles is still less than 20%. In other words, more than 16 million tons of waste textiles in my country have not been fully used each year, which will cause serious environmental protection problems, which not only destroys the ecological environment, but also wastes limited valuable resources.

In April of this year, the National Development and Reform Commission, the Ministry of Commerce, and the Ministry of Industry and Information Technology jointly issued the "Implementation Opinions on Accelerating the Utilization of Waste Textiles" to promote the construction of the recycling system of the resource circulation industry and the use of waste materials to improve the use of resource utilization Efficiency is of great significance to promote the construction of ecological civilization and help the realization of carbon peak carbon neutrality and targets. The "Implementation Opinions" proposes that by 2025, the waste textile cycle utilization system is initially established, which will make the cycle utilization rate of waste textiles reach 25%, and the output of waste textile regeneration fibers will reach 2 million tons. By 2030, a relatively complete waste textile circulation system will be built. The cyclic use rate of waste textiles will reach 30%, and the output of waste textile regeneration fibers will reach 3 million tons. This is also the first time that the development goals of waste textiles are clearly explicitly explicitly used at the national level.

The China Deep Industry Association said that the old down jacket refurbishment business and the regenerative down industry are all active attempts under the national "dual carbon" goal. In the future, the recycling and utilization of waste down products will achieve great development with the support of the policy. The association will continue to pay attention to this, play the role of industrial guidance, and lead the industry to achieve green, low -carbon and recyclable healthy development.

Text | Reporter Shi Xiaofei

- END -

Don't miss it!Chengdu Digital RMB Online Consumer Course continues to be issued today at 12:30

Today at 12:30 noon todayThe last wave of this monthChengdu Digital RMB Online Con...

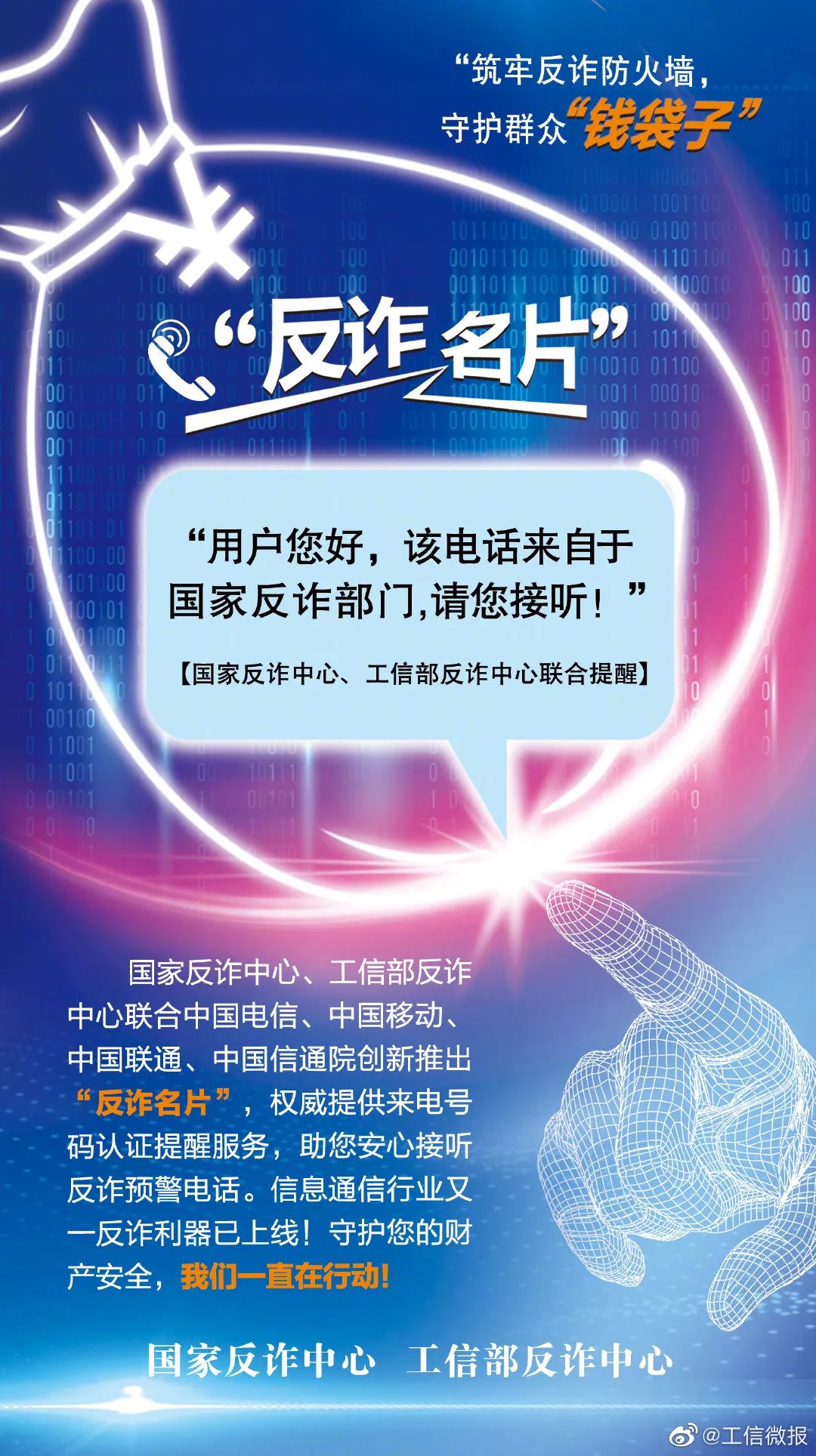

This call must be answered!Rest assured!Don't hang up!

The reporter learned from the Ministry of Industry and Information Technology on t...