Wang Aiying, the Institute of Ningbo Materials of the Chinese Academy of Sciences, "empower" the material: put on the "coat", the material can be corrosive and wear -resistant

Author:Zhejiang Daily Time:2022.07.08

Zhejiang News Client Premier Xie Yue Mao Guangxi Planning Li Jian reporter Weng Yunzheng He Yuankai Sharing Alliance Ningbo Materials Office Gao Xiaojing

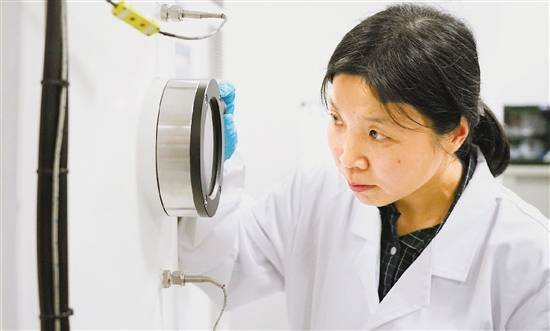

Wang Aiying

Dr., born in 1975, researcher and doctoral supervisor of the Institute of Materials Technology and Engineering of the Chinese Academy of Sciences, and deputy director of the key laboratory of Marine New Materials and Application Technology of the Chinese Academy of Sciences. He has been selected as the National Outstanding Youth Science Fund and the Talent Plan of High -level Innovation Leadership in Zhejiang Province. He presided over more than 20 major scientific and technological research projects including the major equipment of the Chinese Academy of Sciences and the International Innovation Team of the Chinese Academy of Sciences.

Dream quotation

"I have to concentrate on scientific research, improve my skills, and strive to achieve core technologies break through and realize the application of characteristic results."

"Combining what you have learned with the major needs of the country is the value of life and the joy of scientific research."

At the Institute of Materials Technology and Engineering of the Chinese Academy of Sciences (hereinafter referred to as the "Ningbo Materials Institute of the Chinese Academy of Sciences") carbon -based thin film and coating technology team laboratory, through a vacuum coating equipment, people can observe the magical scene -the ghosts passed through Electric 离 emits light purple discharge glow. The ionizing sorbe forms a plasma, and then hits gold, silver and other targets, and is uniformly deposited to the target object, so that the target objects put on anti -corrosion and abrasion -resistant "armor", which can achieve special scenarios applications.

These coating equipment was designed and developed by the team by researcher Wang Aiying. On the basis of not changing the characteristics of the object itself, vacuum coating technology can "wear" a magical "coat" to the material through special processes, giving it superior performance.

Focusing on this magical "coat", Wang Aiying led the team to continuously innovate, not only solved many production problems for regional manufacturing companies, but also assumed the new era of scientific research in the new era of "going to the sea". "Right now, we are related to many cutting -edge projects in the fields of sea -related airlines and deep -sea exploration with domestic institutions. With new surface engineering technologies such as vacuum coating, we can make major equipment in special environments safe and long life." Wang Aiying said.

"I have to focus on scientific research, improve my skills, and strive to achieve core technologies break through and realize the application of characteristic achievements." When talking about dreams, Wang Aiying's tone was gentle and firm.

Coating high pressure resistance to corrosion resistance

Help deep -sea detection

Deep diving equipment should be achieved in a smooth and efficient operation, which cannot be separated from the cooperation of the key power component of the hydraulic pump. For a long time in a high -pressure and high -corrosive deep -water environment, the surface of the hydraulic pump material material is inevitable. How to break the problem?

"We have developed a special carbon -based coating for the pump body, which can not only enhance the tough and abrasion resistance of the pump body under high static water pressure, but also be expected to achieve the safe and efficient operation of the pump without using the additional lubrication medium." Wang Aiying Yingying Tell reporters that the element of carbon itself has magical properties. The optimization and reorganization of carbon and related metal elements can make several microns thick coating with strong, tough, and blunt equilibrium performance, and help deep sea detection.

The pump body of the traditional deep -sea pressure pump is mostly used to lubricate, which is not environmentally friendly, and the service life is short, which cannot meet the demand for long -standing equipment for more than 15 years in the future deep -sea space station. In 2018, Wang Aiying's team, who has been studying in the field of carbon -based protection coating for many years, successfully "unveiled the list" important topic "key component surface lubrication and protection coating key technologies" of the Chinese Academy of Sciences, which provides new ideas for high -efficiency protection of deep -sea hydraulic pumps.

During this time, Wang Aiying paid close attention to the performance test conducted on the deep sea simulation environment.

"With the help of the cooperative unit's scientific test ship platform, the coating we developed on the Western Pacific Underwater underwestern seabed was still intact and rusty after 341 days." Wang Aiying told reporters that once the actual application is put into the actual application, it will help it will help. Improve the special environmental adaptation ability of deep diving equipment to help crack the "stuck neck" problems of related segments.

Speaking of the scientific research stories of these years, Wang Aiying is full of passion and fast speech. Talking about key technical issues, she also excitedly picked up the pen and paper and science to the reporter's popular science: the structure of the coating equipment, the principle of ion beam discharge, carbon element arrangement combination ...

"Surface engineering is a bit like Harry Potter's stealth cloak and Zeus's shield. The more you study, the more you feel mysterious. Until today, there are still many technical problems in the segmented field waiting to be cracked." Wang Aiying said. After receiving a doctorate degree from the Institute of Metals of the Chinese Academy of Sciences, she placed the main direction of research on the important branch of the surface engineering -PVD (physical gas deposition) surface strengthening protective coating. This Shaanxi girl gradually embarked on a "hard core" scientific research. After joining the Chinese Academy of Sciences Ningbo Materials Institute, Wang Aiying, who has accumulated many accumulated in related fields, led the team to undertake major scientific research projects such as the National Natural Science Foundation. Experiments, defense, seminars ... Wang Aiying's schedule is very full.

"It's really busy, but it is still satisfying to combine what he has learned with the major national needs." Wang Aiying said with a smile.

Do it yourself without teaching

R & D of high -end equipment

If you want to be good, you must first benefit your instrument. To achieve breakthroughs in the field of surface engineering, equipment is very important.

Take the vacuum coating process as an example. The first is to generate discharge plasma through the action of voltage and magnetic fields, and then use a series of physical or chemical reactions to uniformly deposit the target ions to the body material. The principle is not complicated, but behind it is the complicated process of multidisciplinary cross -integration.

"A foreign high -end coating machine is tens of millions of yuan, and it is basically customized production. One equipment only corresponds to one or two coating processes. There are very few teams in the domestic coating equipment research and development. Let's do it by ourselves! "Facing the hesitant of his companions, Wang Aiying was cut off.

How to distribute the electromagnetic field? How to control plasma? How to enhance the denseness of the coating by improving the strength of the discharge ... As a team leader, Wang Aiying devoted a lot of effort to equipment research and development. Taking the deep -sea protection project as an example, most of the relevant components are complex cavities. The outer wall coating is relatively simple, and it is necessary to cover the inner wall of these cavities evenly and reliable protective coating. The difficulty is unprecedented.

The light does not turn on the light, and the same is true of similar glowed arc light plasma. How can we introduce the inner wall of the curved cavity in the curved cavity? Data inspection, data deduction, discussion verification ... After hard work, Wang Aiying and colleagues found the breakthrough, and successfully solved the problems with the help of the breakthrough auxiliary anode, external magnetic field coupling and other design ideas.

Talking about a equipment developed independently over the years, Wang Aiying's words are full of pride: "To engage in equipment requires group strength, the biggest feature of our team is that experts in each direction are available. ... I want to play everyone's specialties. "

The gentle Wang Aiying always uses practical actions to make an example and enhance the cohesion of the team in virtue. "On holidays, Teacher Wang often comes to work. No matter how busy, every report and paper will be carefully modified." Said the team member Chen Rende.

Sink down your body

Service industry development

Scientific research should serve economic and social development. When he first came to Ningbo, Wang Aiying was considering: Zhejiang's manufacturing industry was relatively developed, how to apply these research results in the field of surface engineering.

Entering enterprises, running exhibitions, participating in various technical docking activities ... Wang Aiying often finds the opportunity to run the industry. For a long time, she had a deep experience: "Technology workers should sink down and ground."

Ningbo Yongwei Group Co., Ltd. is a private enterprise specializing in the production of air -conditioning compressors. The old chief strategies are quite sharp.

“老总坦率地告诉我们,企业遇到了一个技术难题。空调制冷剂会使压缩机滑片产生磨损,时间长了就会影响空调制冷效能。有没有什么强化防护技术可以解决难题?我们一听, Isn't this the field we are good at? "

Wang Aiying's team developed the carbon -based strong abrasion -resistant composite coating technology for the compressor slide sheet, breaking the foreign monopoly in the segmented field. In order to understand the application of the coating sliding slices, Wang Aiying even followed the entire machine factory in Guangdong all the way to check the testing and analysis of the work data ... Kung Fu is worthy of the people. In 2020 The joint "Key Technology and Application of Popular wear -resistant carbon -based composite coating materials" project won the first prize of Ningbo Science and Technology Progress. In just a few years, the innovative project brought hundreds of millions of economic benefits to the enterprise.

Car engine key components, sewing machines high -speed operating components, high precision work molds, light alloy surface strengthening protection ... In recent years, Wang Aiying team has brought more scientific research results to "bookshelf" to "shelves", better serving the industry develop.

On the one hand, we are committed to solving major needs of national needs such as key protection technology such as sea -related equipment, and serving industrial development. During the scientific research journey, Wang Aiying's pace of dreams had not stopped.

- END -

Digital Baozing 丨 The first digital Baoding Quality City theme exhibition and 2022 Baoding's 7th Internet Conference empower Baoding New Future

Digital Baoding Zhihui Quality CityThe first digital Baoding Quality City theme ex...

GT2 Masters Exploration Edition, Buds Air3 Neo, Notebook Air Zhenjian three new products released

The technology tide brand Realme held a new product launch conference, which offic...