The top 50 in the world, Changsha accounts for 4 seats!These "global leaders" are "China Intelligent Manufacturing"!

Author:Changsha release Time:2022.08.06

Today (6th), the General Taiwan Finance and Economics Center launched a large -scale meling media report "Intelligent Manufacturing China". The reporter will go deep into the intelligent manufacturing factory workshops in 16 provinces and cities across the country for nearly two months. The live broadcast connection, close -up short film and governor interviews systematically reported the latest technical equipment and achievements of intelligent manufacturing in my country, showing the strong vitality and endogenous motivation of my country's manufacturing and real economy development.

Steel plate in the whole car

A heavy truck is offline as soon as 4 minutes of smart factories

Today's first stop of the intelligent manufacturing entered Changsha, Hunan, and the reporter visited the heavy truck smart factory of Hunan Sanyi Group.

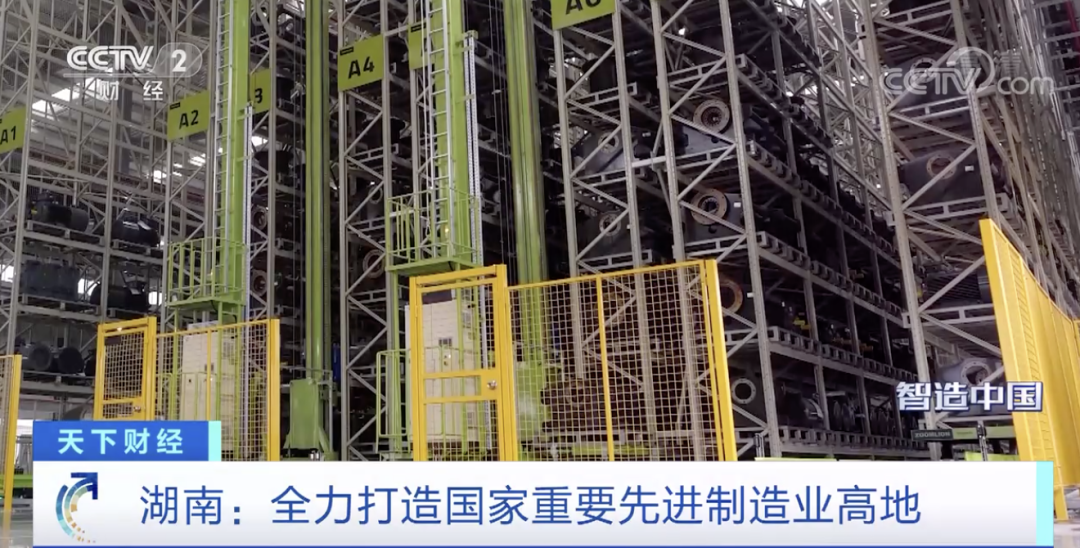

The reporter sat on a unmanned large truck. The truck was born in the super factory of the Sanyi heavy truck in Hunan, and has achieved a test of more than 10,000 kilometers. The area of this factory is equivalent to the size of 31 football fields. The intelligent level of the entire factory is very high, and it can realize "steel plates, the whole vehicle out", and a heavy truck can be offline in 4 minutes as soon as possible.

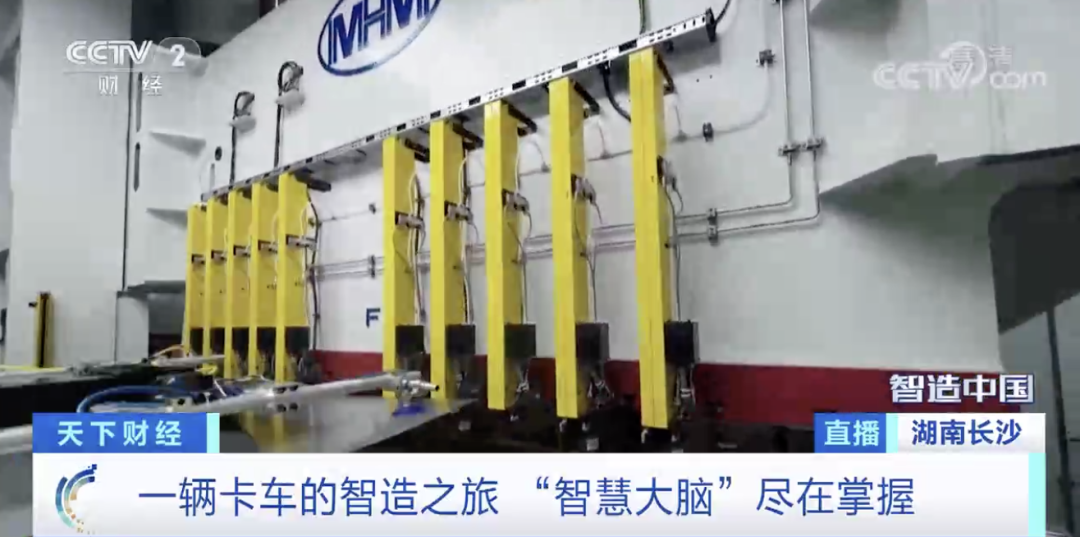

How did the truck make? Entering the factory, the automated stamping production line shaped a piece of steel plate to cause various shapes, that is, the parts of the front. The AGV car is a portal of the factory. They connect all aspects of production in series and send 100,000 components to the specified location every day.

Next is welding, components of different sizes, will continue to work by 184 robots on a 196 -meter -long welding line. The front of the cab.

The next link is coating. The front of the car will be sent to the painting workshop. The 29 robotic arms are working. Some are responsible for automatic wiping, some are responsible for opening the door, and some are responsible for spraying. After about ten hours of operation, the body is put on the coat of different colors, and it will come to the interior workshop, and the dashboard, steering wheel, etc. will be installed here.

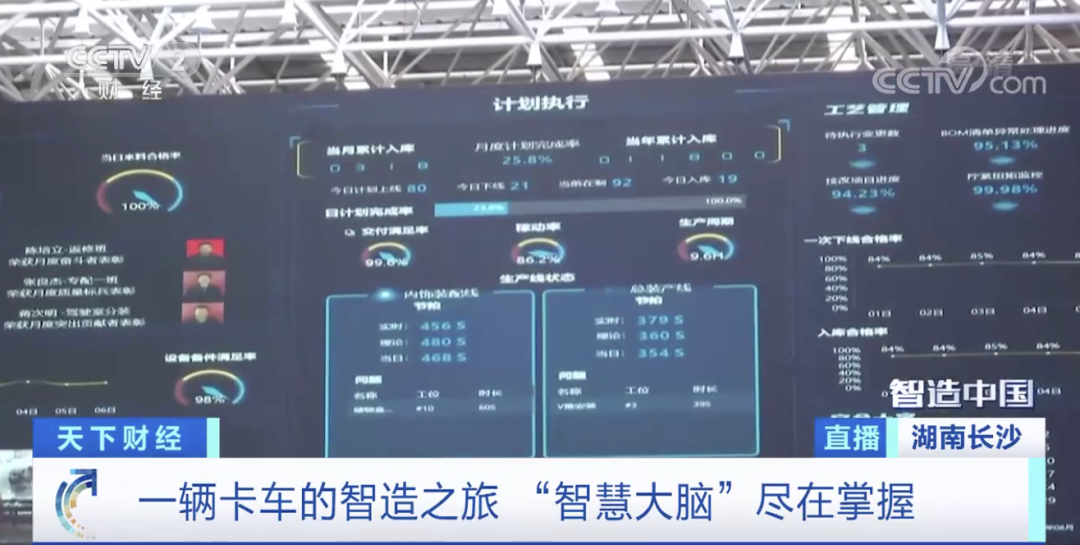

These seemingly smooth operations are inseparable from the control of the wisdom brain behind, that is, a large smart screen, it is an intelligent production management system. From the large screen, you can see all the production processes, so that all manufacturing is in control.

To complete the offline of a vehicle, you need to pass the final assembly production line. The entire production line supports flexible customization and is fully produced according to needs. At present, this production line has been offline, with more than 400 different cars, of which more than one -third of them are heavy trucks of new energy.

It can be said that every truck from this smart factory runs on the road network across the country, and is perceiving the breathing and pulse of the Chinese economy. Behind this is the transformation and upgrade of smart manufacturing in China.

Changsha, Hunan: Drinking coffee open shield machine

Intelligent counterattack of heavy weapons

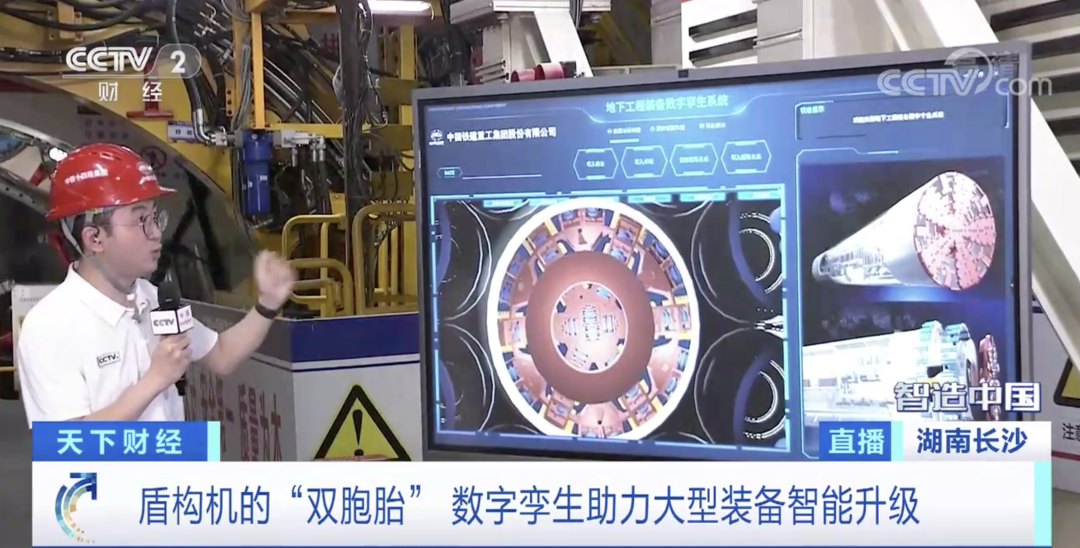

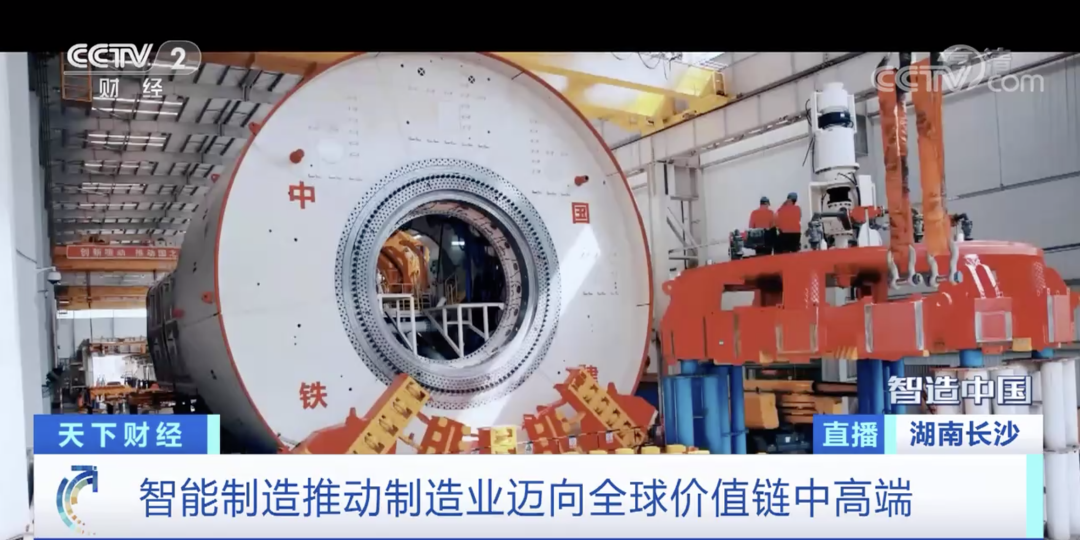

Intelligent manufacturing is not only reflected in the production process. After the product and equipment are put into use, intelligent manufacturing technology continues to play an important role. The reporter came to the construction site of the Xiangjiang River Crossing Tunnel in Changsha, Hunan. In the depth of 32 meters underground, a shield machine with a total length of 136 meters is at a speed of 6 meters a day. Essence

In the past, the construction of the tunnel was actually very dangerous and the environment was very bad, but now, more than 30 meters under the ground, the driver can blow the air conditioner, drink coffee, stare at the screen, and perform operations. This is inseparable from the help of intelligent manufacturing technology. One of the critical technologies is called "digital twin". As the name suggests, "digital twin" is to create a "twin" in the virtual world for the shield machine.

On the right rear of the reporter, it is the core component of the entire shield machine -the blade. It is relying on the blade to continuously rotate that the shield machine can cut the underground rock and achieve continuous progress. On a screen next to the reporter, the real -time picture of the shield machine "digital twin" system is displayed.

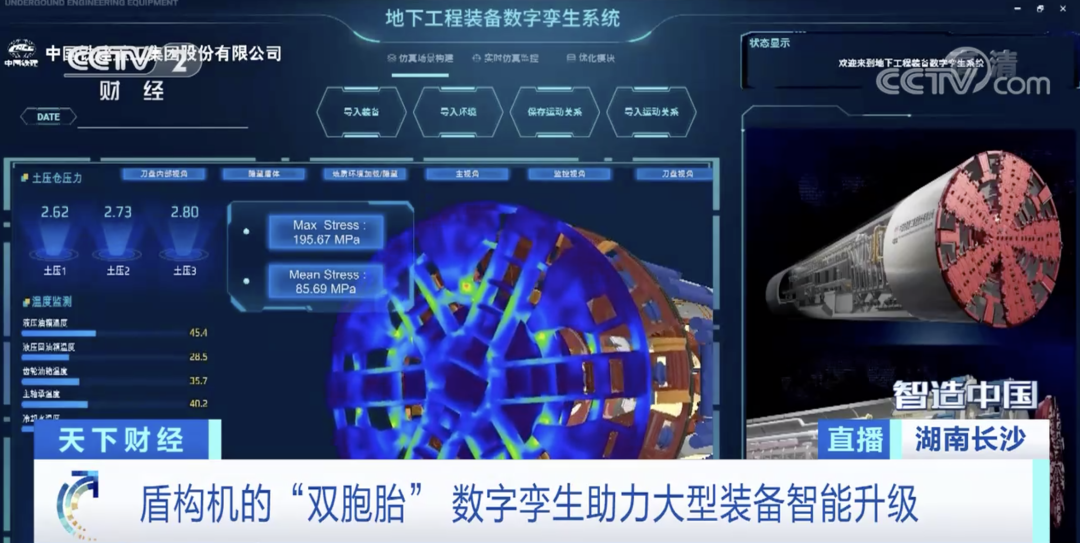

What is the role of this "digital twin" system? The reporter saw the second picture. The shades of color on the screen represent the force and wear of the shield machine. Some yellow and red areas on the screen represent the areas with severe wear.

During the operation of the shield machine, the "Digital Twin" system will collect various data of the shield machine in real time. For example, its operating data, underground environmental data, etc., realize intelligent analysis, monitoring, and even independent decisions, making the entire construction process more intelligent, secure and efficient. And after the accumulation of these data back to a certain degree, the designer of the shield machine can use these data. In the future, it will improve its performance in the design and development and manufacturing of the next -generation shield machine products. It is of great significance to a large -scale equipment worth 100 million yuan.

The empowerment of intelligent manufacturing technology has made Hunan manufacturing industry at the forefront of the country and the world. Among the top 50 construction machinery, 4 Hunan companies were on the list; the entire industrial cluster was 280 billion yuan, ranking the top three in the world. Many technologies have been used in emerging industries such as new energy vehicles, photovoltaics, and wind turbines, which not only bring the opportunity to transform and upgrade enterprises, but also allow Hunan's manufacturing industry to move forward towards the mid -to -high end of the industrial chain value chain.

Hunan: Make every effort to build an important advanced manufacturing highland for the country

In recent years, Hunan proposed to build an important and advanced manufacturing highland in the country. So, what good experience does Hunan have in this process? What problems do you need to focus on? A reporter from Financial Channel made an interview with Chen Fei, deputy governor of Hunan Province.

Four Hunan Construction Machinery Enterprises, including the top 50 global construction machinery manufacturers in 2021, released the top 50 list of global construction machinery manufacturers in 2021. Last year, the scale of Hunan Construction Machinery Industry Cluster reached more than 280 billion yuan, becoming the world's third largest construction machinery industry cluster, and its operating income and total profits have ranked first in the country for 12 consecutive years. This achievement is inseparable from the efficiency improvement brought about by intelligent manufacturing.

Chen Fei, a member of the Party Group of the Deputy Governor of the People's Government of Hunan Province: Zhonglian Smart City is the most advanced production line in our construction and operation. Digitalization, networking and intelligence.

In recent years, many leading enterprises in Hunan have invested in building a number of digital and intelligent transformation projects. A number of unmanned factories and black light production lines have become the industry benchmark. In 2021, Hunan Province's manufacturing technology transformation investment increased by 20%, and the growth rate was higher than that of the province's fixed asset investment 12 percentage points.

Chen Fei, a member of the party group of the Hunan Provincial People's Government: Digital transformation is mainly to rely on corporate investment. We introduced the promotion regulations of advanced manufacturing last year, which is the first in the country.

From March 1st this year, the regulations that officially implemented will support the digital transformation of enterprises, parks and industrial agglomerations from many aspects such as financing, infrastructure and other aspects.

Reporter Zhang Weijie: In the process of building an important advanced manufacturing highland, what are the shortcomings in Hunan's manufacturing industry? How to make up for the short board?

Chen Fei, a member of the party group of the Hunan Provincial People's Government: Our manufacturing industry must move towards the mid -to -high -end, truly becoming a manufacturing power, and a lot of work to do, including many materials in the construction machinery industry depend on import.

To this end, Hunan Province and the Chinese Academy of Engineering jointly established the Yuelu Mountain Industrial Innovation Center to gather innovative resources from universities, research institutes and enterprises, and carry out technological research and development tackling.

Source 丨 Changsha Publish Comprehensive

Material 丨 CCTV Finance

Edit 丨 Tangwei School Fight 丨 Wen Chunyan

Review 丨 Du Jin

- END -

Developing "next -generation cars", Chinese car valley creates a safe, controllable, more resilient car supply chain

Luo Junmin, deputy secretary -general of the China Automobile Industry Association...

deal!Volkswagen China ’s management structure is adjusted, Bearing will take over Feng Sihan as CEO on August 1

The long -rumored Volkswagen Group (China) CEO change has finally landed.On June 1...