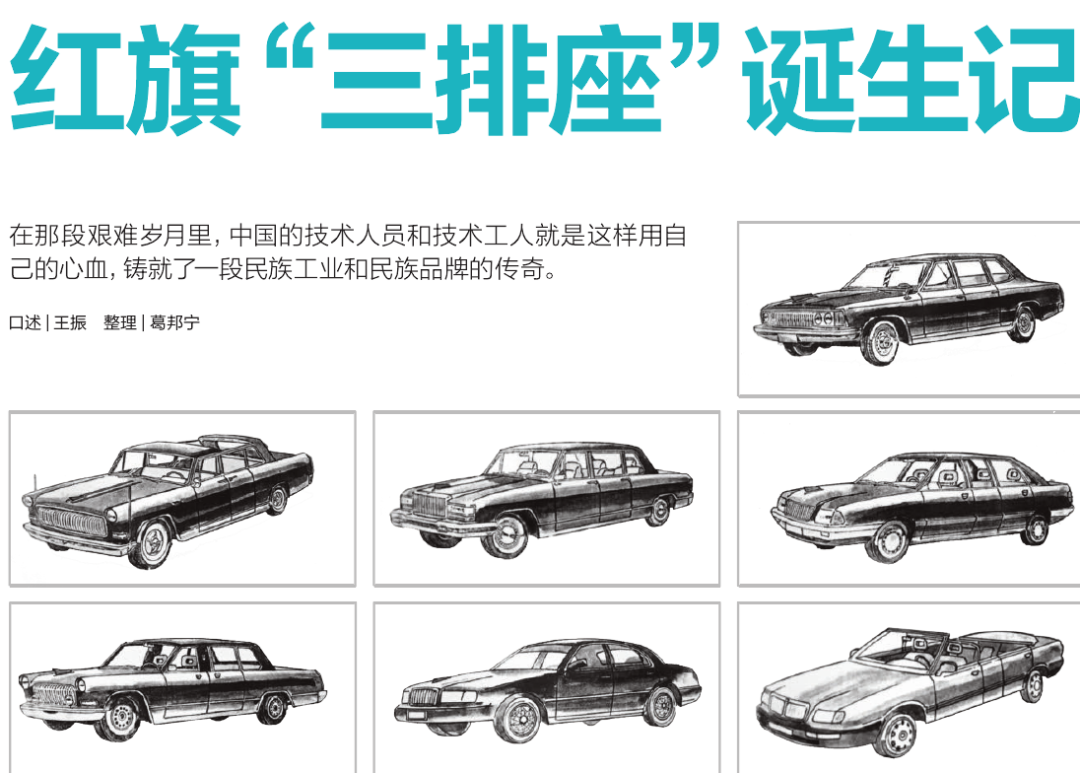

Oriental luxury car | Red Flag's "Three Rows" Born

Author:Writer Wen Digao News Agency Time:2022.07.04

1

To say that the red flag "three rows of seats", the first thing to say is naturally "two rows".

In 1958, when FAW's "two rows of seats" cars CA72, there were no sedan factories, and various components were scattered. For example, the engine workshop production engine, the chassis workshop production chassis, and finally concentrated.

The "two -row" sedan has been produced until 1960. As a review of the 10th anniversary of the founding of 1959, it was stopped for a period of time due to quality problems.

In 1963, the car factory began to focus on the "two -row" problems, and found 42 quality problems, 20 of them, 20 items and 22 types of problems. The so -called type of problem is the key problem that cannot be left without solving, such as brake bias, engine turning off, door closes, and cannot be opened. Others such as cars are ranging everywhere, horn do not ring, etc., which belong to the second category.

Subsequently, the sedan factory proposed the slogan of "quality first" and established more than 20 quality research teams, each of which includes craftsmen, designers and manufacturers. It took nearly 4 months to solve all these quality problems.

On October 1, 1964, the 15th anniversary of the founding of the New China, 20 newly improved "two rows" were sent to Beijing. These cars were used well in Beijing. The central government replaced the Soviet Gim sedan to welcome foreign guests who participated in the National Day ceremony.

After talking about the "two rows", it is time to talk about "three rows".

"Three -row" refers to the CA770 of the Red Flag Search, which has a specific historical background.

At that time, the central leaders were all in the Soviet cars. Among them, Geis 115 bulletproof insurance vehicles are available for 5 people including Chairman Mao and the Standing Committee of the Political Bureau of the Central Committee; Geis 110 three -row seats are used for leaders of the Vice Premier of the Political Bureau of the Central Committee. In addition to these, there is also a domestic Gim car produced by the Soviet Golki Motor Factory for the provincial party committee secretary, commander of the military region and ministers.

In the early 1960s, Sino -Soviet relations deteriorated, and all Soviet experts in China were withdrawn. The Soviet Union no longer provides car accessories, causing these Soviet cars in China to have no parts to replace. When I went to Beijing for an investigation, I found that Gis 115 and Gis 110 stopped.

In this case, under the leadership of the machine department, we are determined to change the high -end sedan we produced for the central leaders.

In 1964, Minister Duan Junyi came to FAW: "The central leadership comrades sitting on the old (CA) 72 must not work. It is two rows of seats, and the quality is not good.

In 1965, the order came down to try out a three -row red flag high -end car with an advanced level by October 1.

2

What is it easy to produce "three rows"? The first thing that requires is modernization. What was modernization? No one knows at the time. I couldn't go abroad at that time, and I didn't know what foreign cars were. The requirements of the "three -row" shape are beautiful, generous, solemn, and rich in national colors.

We quickly find a prototype. At that time, there was only a Rolls -Royce of the British Queen in our hands. We want the best car, but no one sells it to us. The Automobile Bureau gave us an idea, let's see the Mercedes -Benz 600 sitting by the Vice Premier Chen Yi of the State Council.

Mercedes -Benz 600 PULLMAN (Data Map)

I took a few people to Zhongnanhai and happened to meet Chen Yi's driver Lao Li. He was rubbing Mercedes -Benz 600. Chief Cao Ke of the Central Security Bureau said: "This is the director of the FAW car factory, they want to see Mercedes -Benz 600."

Lao Li was very polite, but very refreshing: "Look at the car of others, and then look at the two rows of cars in your two rows, how can we do it? The car manufacturer eats in vain? So, I'll pull you you first. A circle. "

We sat on the Mercedes -Benz 600, went out of the No. 6 Gate of Zhongnanhai, followed Chang'an Street, and drove to Wusong. The police knew that this was Chen Yi's car (only this one in the country at the time), so we were unobstructed all the way, and it felt really good.

However, it is not necessary to see any name, at least one test and amount can be measured to know the specific size. We applied to the ministry, can we make Mercedes -Benz 600 sample cars.

In 1958, the first domestic red flag sedan was born

Chen Yi didn't agree at first, but then there was a turnaround. Premier Zhou told him: "You can forget the car to others, they make a high -end car for us."

At this time, less than half a year before the National Day, the "three rows" entered the design stage. The technical personnel participating in design and technology have started research on engines, gearboxes, brakes, and dual -tube.

Let's study the prototype first. Rolls -Royce looks noble and long body, shakes a little when testing, but the interior is good. The Mercedes -Benz 600 has a good appearance and is very stable to open, but the following is always "gurgling", which has a bad relationship with the pavement of our country at that time.

Next, the "three -row" vehicle is set to 5.98 meters. The Rolls -Royce car of the Queen of the United Kingdom is about 6.2 meters and the 600s of Mercedes -Benz is about 6.4 meters. Why does our chief design design less than 6 meters? Because at that time, there were many Beijing Hutong at that time, and the body was short. Although the vehicle is shorter, both Rolls -Royce and Mercedes -Benz 600 have the functions, such as the sound insulation glass in front, the automatic rear seat in the rear. Now the design of the car must be kept secret, but we were open at that time, and the more people, the better. Seven people designed 7 sludge models respectively. At noon, the entire factory employees took the lunch box as a judge to pick and choose the 7 sludge models, and to modify their opinions. Later, we concentrated the advantages of each model and made a 1: 1 main clay model. This is the appearance of the red flag's "three rows".

3

When the car factory was preparing to make a sample car, an accident arrived unexpectedly.

One day in May 1965, Changchun storms and rain and lightning. The tens of thousands of square meters of factory buildings in the car factory were covered with brick and wood during the "Great Leap Forward" period. Where can I stand the impact of the storm and rain, and some places are cracked. When I came to the workshop, I saw the house cracking and blocked the lathe, threatening the safety of workers and equipment.

I hurriedly called the general factory: "Director Guo, you come over, this problem is big, the factory building is going to collapse. I can be responsible for other things, but I can't afford the life of life."

Guo Li immediately took the people at the Infrastructure Office to check the factory building. On the spot, the factory building was urgently repaired, and the car factory moved immediately.

"We are producing a red flag sedan, what should I do now?" I was a little worried.

"I'll find you." Guo Li said.

The two of us rushed to each branch to ask for help. Everywhere, Guo Li said: "For 61 brothers, everyone has to assist the car factory."

It took us for a long time to take 7 units in the 6 units of off -road, engine, molding, chassis, accessories, and education building cafeteria. Coupled with the general loading line of the car factory, the Red Flag is distributed in 8 places to produce.

After the venue was determined, we rushed to move the equipment with heavy rain. The car factory relied on its own strength to move hundreds of equipment to 7 venues after half a month. The "three -row" prototypes and 20 "three -row" sedan sent to Beijing before "May 1" in 1966 are basically made in decentralized factories.

During this period, while relocating and trialing, technical workers have played an extremely important role. There are many difficulties in the trial process, and there are almost no molds, which depend on them.

I have always insisted on a point of view: the role of technical workers must not be ignored whether it is past or now. But now the facts are the opposite. We pay more attention to technology and experts, but do not pay attention to capable craftsmen.

The body assembly adopts the "three combinations" of designers, craftsmen and workers. After the length of the car and the width of the car is determined, according to the height, body shape and ride demand of the central government, the internal size of the car is determined. Now you can use computer to design these, but at that time, it was not easy to handle, and only different people could sit inside and tested.

In order to design the size of the cab, we found several experienced drivers who drove and let them represent the three types of people with fat, thin, and short. Essence

The wine cabinet and tea cup were first designed behind the car, but later canceled. The design of the suspension device involves many principles. Under the cooperation of the workers, the designer Hua Fulin boldly made improved design so that they could adapt to the road at that time.

We pioneered the frame -shaped frame on the "three rows". This was seen by designer Zhu Zizhi in a foreign car magazine. At that time, there was no precedent for foreign cars. Frame -shaped frames are difficult to do. First, you need to design molds, and you need to find materials after designing. I asked Zhu Zizhi to set up a group, and I also tuned two people: welded craftsman Sun Dechang and the eighth -level fitter Qian Zeng Rong.

After the first design, the effect of the frame -shaped frame is not ideal. Some people start gossiping: "You see, you want to make the limelight, you can use it without using it, you can use it? You can design it?" Other people think that if the time is delayed, it may be wrong.

For this reason, Zhu Zizhi came to me specifically. I said, "Don't care what they say, let's keep the time and continue to do it. Marxism is not a fortune -telling, let's practice practice."

In the end, the trial -based frame loading effect was very good.

4

On September 12, 1965, we installed the first "three -row" sample car. On September 19, the car factory arranged to send the car to Beijing to Beijing. Although I didn't go, they called the situation every night.

On September 20, the central leaders and comrades of the State Council watched the "three -row" sedan.

At 9 pm that day, Comrade Peng Zhen wanted to watch the car. He was a member of the Political Bureau of the Central Committee, secretary of the Secretariat, and secretary of the Beijing Municipal Party Committee. Guo Li, who has been transferred to the deputy minister of the machine department, took the comrades of the delivery team to drive the "three -row" sedan to the residence of Comrade Peng Zhen. When he saw it, he was very happy and asked to try a new car.

On Chang'an Street, Peng Zhen made the driver faster. The driver said that the speed has reached 100 kilometers per hour. "I didn't think it was so fast in the car, it was really a good car." Peng Zhen was very satisfied with the appearance, performance and interior of the car. "We must use our own car to pick up the president of other countries." Seeing behind the car At the event seat, Peng Zhen said happily: "Premier Zhou welcomed the foreign guests very tired. With this seat, he could lie down and rest." When he saw the side label of the red flag, he asked what it meant. Guo Li replied that the three red flags represent the main route, the "Great Leap Forward" and the People's Commune.

Peng Zhen said, "That's not complete, and Mao Zedong's thought red flag, just use a red flag." Later, after the decision of superiors, the side standard only retained a red flag.

After watching the car, Peng Zhen said, "You leave the car, I will drive to the Politburo tomorrow, and give them to the chairman and the prime minister."

This is difficult. We only made a prototype, and we gone after the car was left. Guo Li said: "Leave Comrade Peng Zhen, he can do publicity."

Peng Zhen was sitting in the red flag "three -row" sedan every day to Zhongnanhai. Many leaders want to take this car and ask him to ask him. Where is this car? When they heard that it was made by FAW, they asked the car from the ministry.

At the end of 1965, we received instructions from superiors that in 1966, we must produce 20 red flag "three -row" sedan before the "May 1st" section for leaders at the Political Bureau of the Central Committee. In other words, 20 new cars should be produced within 5 months.

5

It is difficult to complete this task. First, the product design drawings are not complete. When we made the first prototype, we prepared some drawings and workers, but were not complete.

On October 4, 1965, the car manufacturer's general meeting mobilized everyone to fight for 20 "three -row" sedan.

The Heat's "battle" began. The comrades of the body design group were lying on the cold picture board and designed drawings, and more than 1,000 cards were drawn within two months. After drawing the drawings, the workers knocked the model by hand. The technicians and workers of the Gongguang Design Group created hundreds of workers. Some parts that are too late to engage in workers are done by the technology of old workers.

For example, the control arm of the suspension part was milling from the master of Shanghai master Chen Kunxiang; the active and passive rotor of the high -pressure oil pump was grinded by the eight -level worker and the model workers. Good grinding beds; hydraulic gearboxes are designer Feng Jinwei, director of the workshop Dong Zhengbu, engineer Huang Yuanrong and old workers Yu Zhaofeng and Yu Xueyi together. At that time, the body covered group was also located in the cafeteria of the Education Building. The team leader Liu Yubao took the workers, with a hand hammer and a flat shovel, steel plate plus steel, and took 17 days to make the front and rear fender and the eight large coverage of the front and rear covers. Tire.

The door lock of the "three -row" is produced by the Shanghai factory. It cannot be opened after installing the car, and it cannot be closed after opening. The old workers of the Shanghai factory took the door locks away from Changchun to study what problems were to study. The designer re -chart the modified door lock. The old workers brought the design picture back to Shanghai. Without the mold, they made a new lock by hand.

I often lamented that the successful production of the "three -row" red flag sedan was first relying on a group of good engineering and technical personnel, followed by a group of real old technicians. Everyone says that the atomic bomb is good and high -tech, but no matter how good the design is, who does it? Also depends on old workers. At that time, the highest skills of workers were level 8, and the average skill level of the car factory workers was 6.8, which was already very high.

6

Due to the tight time and heavy tasks, many workers living in the city, such as Wang Mingshan, Xu Wenheng, and Zhang Liu of the car in the city, have spontaneously moved to the factory to live in the factory. They went upstairs and cushions, and took food steamed rice themselves.

One night, we gave the workers boiling water, and encountered the Qiu Xianglu of the water in the halfway, carrying a few rice pockets in our hands. When asked, we knew that in order to let the workers sleep more for a while, they volunteered to steam breakfast every day.

It can be said that when the "three -row" sedan, everyone in the car factory was mobilized. I have said, I do n’t know how my children grow up, because I am in the factory every day and I am with the workers.

Dinner is a problem. The workers' breakfast can be solved by their own food, but what to do with dinner? I go to the people of the labor and capital offices of the General Factory: "The workers are too hard, and the food is not enough. I often do it in the middle of the night. Solving a meal? "

People from the Labor and Management Division did not agree, saying that there was no such rule. We said it, and finally they agreed to give overtime fees: two cents an hour.

The workers have opinions: "We are not for these two cents. Why do we run here for two cents in the middle of the night?" They said, "We are for the Red Flag, to let the central leaders sit on the red flag as soon as possible."

I went to Zhao Xueyi, secretary of the party committee of the General Factory again: "Our cadres are okay, we can go home to eat, come and come again, but the workers live too far, and I can't go back to work (work)."

Zhao Xueyi said: "So, let's give the workers a meal according to the standard of four cents, but the workers need to get a grain ticket and buy meals in the cafeteria."

At the beginning of 1966, 20 "three -row" sedan entered the tackling stage, and the major repair project of the main project of the old plant was about to be completed. In order to eliminate the management difficulties brought about by decentralized production, the car factory mobilized the infrastructure, mechanical department and power department, and proposed to shorten the infrastructure time and let the decentralized production departments move back to the old factory within 3 months. It stands to reason that after the infrastructure is done, it is impossible to restore production so quickly. We took the infrastructure workers and all comrades of the mobile department to the line. At that time, the director of the Infrastructure Division Cao Xin disagreed and said that it was dangerous. Later, under the coordination of the deputy factory director Liu Diandong, we reached an agreement with the Infrastructure Department: the infrastructure was dry during the day, we did it at night; they were doing it on the east and we were doing it on the west.

In addition to ensuring normal maintenance, the mobile department also needs to be installed with the capacity network and various pipelines. When they set up the scaffolding, they put on a simple springboard; the pipes with ventilation of the heating equipment weighed hundreds of pounds, and they carried them with one shoulder. The comrades of the Quality Inspection Office were touched and said that they had never seen such a work.

The entire plant soon realized the kinetic energy seven -pass, and the car factory resumed centralized production.

In March 1966, the "three rows" began to assemble in the new plant.

The main assembly workshop director Lu Baogen was a worker, and he was particularly excited at the mobilization meeting. He said loudly, "This is the time when we are all the workers in our pretending workers." Jiang Naiquan, an interior fitter, was called "Little Tiger". After completing his own task, he helped the collaboration department to suppress the mold. In the case of new collaborative parts, the old worker calendar Jin Yuan engraved the front and rear side decoration parts.

After 20 cars are made, each car must complete various performance tests and 1,000 kilometers of running -in test. The car could not be on the road during the day, and I could only run at night. It was very cold in Changchun Night in March. The front and rear windshields produced by Shanghai Yaohua have not been delivered. Sun Xianwen, the leader of the entire vehicle adjustment team, convened an excessive technical personnel and a technical worker to form 5 carts. Each group was equipped with 4 cars. Essence They put on cotton coats at night, cotton hats, and hurried time for debugging.

After the windshield was delivered, in order to obtain the data of the warm air system, in the late night, the vehicle test personnel and the test workers drove the car to the wild, repeatedly opened the window, and measured the data all night.

7

On April 20, 1966, the car factory completed the task 10 days in advance.

On the 21st, FAW sent more than 20 drivers to send the car to Beijing to reach the Yongdingmen Railway Station.

The scene at that time was very spectacular. The "three -row" sedan, which has not been on the card, sailed from Yongdingmen Station to Chang'an Street, becoming a beautiful landscape. On both sides of the road are full of onlookers, including Beijing citizens and foreign journalists.

The batch of cars quickly distributed different central leaders.

On April 23, the second day when the Hongqi sedan arrived in Beijing, the party group of the first machine department sent a congratulatory message to the FAW -General Factory: warm congratulations to the first batch of "three -row" Hongqi cars in advance.

On April 29, the car factory held a conference, one was to celebrate, and the other was to mobilize everyone to complete the production tasks of 100 vehicles throughout the year.

In that difficult years, Chinese technicians and technical workers used their own efforts to create a legend of a period of national and national brands.

Author: Wang Zhen, Ge Bangning

Recommended books

Source: "Chinese Workers"

Editor -in -chief: Nala

Council: Wei Wei

Trial: Kong Ping

- END -

Rolls -Royce's "armored vehicle" appeared, only one world!

Recently, such a unique and unique luxury car was circulating on the Internet -6X6...

The highest subsidy for buying a car is 26,000 丨 The anchor said today's Da Wuhan

Data-version = 0 data-vwidth = 854 data-vHeight = 480 transcoding = 1 / On June 17, the relevant person in charge of the Wuhan Economic Development Zone Science and Economic Bureau said that