Make a car like a toy?10 days 7!This section is hot, the industrial chain company said that ...

Author:Broker China Time:2022.07.23

Source: E company ID: lianhuacaijin

Make electric vehicles like a toy car, Tesla CEO Musk's idea is gradually becoming a reality.

Unlike the tedious traditional process such as stamping and welding, integrated die casting is like kneading dough. Through large tonnage die casting machines, the decentralized aluminum alloy components are integrated and shaped to achieve the lightweight of the car.

As the penetration rate of new energy vehicles increases the demand for lightweight, integrated die casting has attracted much attention from the market. The upstream and downstream of the chain was restless.

In the secondary market, the concept of integrated die casting has remained high. In the past month, the car integrated die -casting index has risen by 25%. Chunxing Seiko has recorded 10 days and 7 boards, and Holi Technology rose 11 times in January. At the same time, on the interactive platform, more than 10 listed companies were asked if investors were involved in integrated die -casting technology and applications.

Is the integrated die casting an irreversible trend or a temporary virtual fire? "Everyone wants to seize the opportunity of development, and at the level of capacity or technical level, they want to prepare in advance." An internal personnel of an A -share die -casting enterprise told the Securities Times · E Company reporter that since May this year, the integrated die -casting has been rapidly serving. The company is accelerating the pace of layout.

At the same time, some people in the industrial chain company bluntly stated that the prerequisites for integrated die -casting profit are high, and many companies in the industry are still in the early stage of business reserves.

OEMs of the new technologies expanded

In the traditional car production solution, dozens of or hundreds of parts should be assembled and welded. After integrated die casting, the casting machine can be implemented by the die -casting machine and mold at one time.

In 2019, Tesla first proposed integrated die -casting technology and was used in the backboard of Model Y the following year. After Model Y adopts an integrated die -casting process, the body weight has been reduced by nearly 30%, the cost is reduced by nearly 40%, and the mileage increases by 15%. The manufacturing time is shortened by 1 to 2 hours required for the traditional four -step process to 3 to 5 minutes.

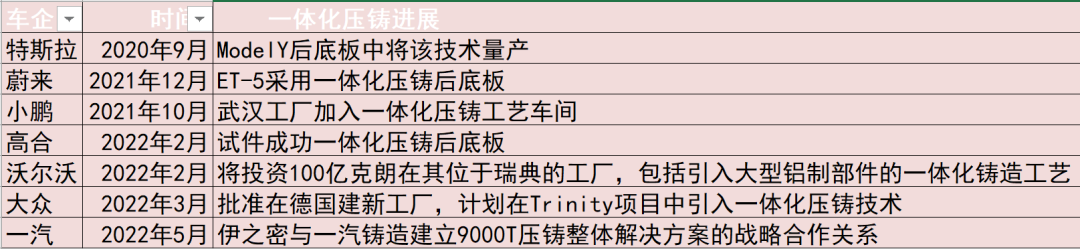

Since then, new forces such as Weilai and Xiaopeng have also followed up the integration of die -casting technology. Weilai ET-5's post-bottom plate application integrated die-casting process achieved a weight loss of 30%, and the trunk space increased by 11L. Xiaopeng will use large -scale integrated die -casting technology on the new pure electric platform in 2023.

In

"The advantage of integrated die -casting technology is to press all parts together, reduce the manufacturing cost, reduce the weight of the body, and make the production line and process simple." Jiangxi New Energy Technology Vocational College of New Energy Automobile Technology Xiang told the Securities Times · E company reporter.

For new energy vehicles, the significance of integrated die casting lies in lightweight and driving the same mileage. The less electricity required for the body. At the same time, reducing the weight of the car can reduce the pressure on tires and braking systems, thereby extending the service life of these components.

It is worth mentioning that the technology whirlwind of integrated die -casting has been scraped by a new forces of the car to traditional OEMs.

In February of this year, Volvo announced that it would invest 10 billion krona to upgrade factories in Sweden and introduce integrated casting processes. Volkswagen also needs to introduce a new factory for integrated die -casting technology for the Trinity project. In May this year, Izi Mi and FAW Casting strategic cooperation signed a LEAP9000 super large die -casting machine.

At present, car companies are applied to electric vehicles more in order to reduce costs and increase efficiency.

"The cost of aluminum use is relatively higher than the cast iron cost. Integrated die -casting also requires heat -free treatment materials. From the perspective of later maintenance, it is not as convenient as cast iron. The car as a steel object has its best choice. "Cui Dongshu, Secretary -General of the National Passenger Vehicle Market Information Joint Association, analyzed the Securities Times · E Company reporter's analysis that electric vehicles can lose weight through integrated casting aluminum alloy. Generally speaking, integrated casting is more suitable for electric vehicles. For In traditional fuel vehicles, it should be unsuitable.

The vehicle tends to the "sandwich" structure

At present, it is mainly the backplane of the integrated die -casting process in the market. However, with the optimization of the process, the model of casting the casting of the car body is expected to increase in the future.

"This year's integrated die casting application scope of the transition from the backplane to the front cabin, the battery tray transition, the front cabin and the battery tray have related plans, and domestic OEMs are also trying. In terms of, the needs of integrated die -casting equipment and materials will double. "A person in the die casting industry told the Securities Times · E company reporter.

The focus of the integrated die casting process is that the components are large -scale, and necessary steps such as heat treatment need to be treated when casting aluminum alloys. The heat treatment will cause problems such as casting deformation to limit the application of aluminum alloy on larger automotive structural parts. As a result, heat -free processing materials have become one of the key factors in integrated die -casting processes.

In a survey in March this year, Lizhong Group mentioned that this year is a year when the deep cooperation of the integrated die -casting industry and further landing in mass production is also the first year of the company's heat -free treatment alloy development. It is expected that the future demand will increase significantly in the future. Entering the rapid development stage in 2023, and entering the market outbreak from 2024 to 2026.

Theoretically, integrated die -casting can be applied other than the white body parts other than covering parts and some suspension parts, including body structures and seat skeleton. Guotai Junan Securities analysis, new energy vehicle shell products can also be applied for integrated die -casting, with higher technical maturity. At present, the structural parts that are the first to achieve integrated die casting are the body chassis, including the front body assembly and rear floor assembly. It is expected that in the future, it is expected to be in the middle floor assembly, door frame, auxiliary frame, lower body assembly, A pillar and B pillars The seat skeleton and the entire white body gradually penetrated. In addition, Guangfa Securities Research Report pointed out that although the previous integrated die -casting is due to the limitation of production capacity and metal material performance, integrated die -casting battery packs are still mostly used for small energy battery packages of hybrid models, but with the performance of various types of alloy materials in the future Increasing, large -scale die -casting machines and other capacity capacity, large -energy battery packs of pure trains are also expected to achieve integrated die -casting.

The integrated die of the front cabin, the rear chassis and the battery tray makes the body structure greatly simplify, and the entire vehicle tends to the "sandwich" structure.

Many institutions believe that except for the coverage parts, the stamping and welding links of the remaining body components may be replaced by die casting processes. According to the calculation of Tianfeng Securities, the market space of integrated die -casting starting from 2023 will usher in a rapid increase. The market space of domestic integrated die castings is expected to reach a scale of more than 30 billion yuan by 2025. The annual average of 2022 ~ 2025 will be The compound growth rate reached 238%.

"Bettings" upstream and downstream of the industrial chain

In addition to the heat -free treatment materials, the upstream of the integrated die casting also includes the die casting machine equipment and molds. The midstream is the die -casting business, and the downstream is an OEM.

"At present, the business model of integrated die -casting applications is based on the midstream die -casting plant. Overhafeites are purchased from the die -casting plant. From this perspective, the performance of the die -casting plant is relatively high. From the long run, some OEMs also also Will do die casting by yourself, this will have a certain impact on the competitive pattern of die -casting plants, and the industry's gross profit level will decline. "A car industry analyst who is unnamed to tell reporters that the die casting machine on the upper reaches of the integrated die casting belongs to the first first. Investment, buying machines according to the corresponding models, the technology of die -casting machines is also iterated, and the demand for materials and equipment will increase with the increase of application models.

With the continuous improvement of the penetration rate of new energy vehicles, all aspects of the industrial chain are linked to compete for "betting" integrated die casting.

Hong Kong stock company Li Jin Technology recently announced that its subsidiaries are intelligent to build a large -scale die -casting machine production base at Hangzhou Bay New District, Ningbo. It is expected that it will be completed in production next year.

On July 11, Tuopu Group announced that it intends to issue a convertible bond of not over 2.5 billion yuan, for an annual output of 1.5 million lightweight chassis system construction projects, and an annual output of 3.3 million lightweight chassis system construction projects.

Ekodi also recently announced that it plans to acquire 67.5%of Fuller's 67.5%equity for 298 million yuan. The target company is mainly engaged in the research and development, production and sales of precision die castings of zinc alloy.

In addition, the concept of integrated die -casting has also been robbed by funds in the near future, and has obtained investor betting. Chunxing Seiko 10 days, 7 boards, Holi Technology rose 11 times in a month, and the stock price of Guangdong Hongtu rose three times within two months. On July 22, Guangdong Hongtu rose again, reaching a record high, with a turnover of 1.371 billion yuan and a renewal rate of 7.28%. After the data of the Dragon and Tiger List after the market, a net special seat of a special institution sold was 16.2652 million yuan.

At present, a number of integrated die -casting industry chain companies have released their performance trailers. Guangdong Hongtu is expected to have a net profit of 217 million to 230 million yuan in the first half of the year, a year -on -year increase of 65%to 75%; Wencan's net profit in the first half of the year increased by 70.56%to 97.85%. Regarding the reasons for the growth of performance, the above companies did not clearly mention the impact of integrated die casting.

Guangdong Hongtu said that the company completed the transfer of equity transfer of Baolong Motor's equity, actively responding to market changes, and reducing the adverse effects of external environment changes such as epidemic and raw material fluctuations on operating performance. Wencan said that in addition to the customer lack of core and the company's sales orders, the company's new energy vehicle customers and new energy vehicle products revenue increased in the first half of the year, driving the company's gross profit growth.

The layout of listed companies in integrated die casting has also attracted attention from investors. According to the insufficient statistics of the Securities Times · E company reporters, in the past week, there are more than ten listed companies being questioned as questioning the integrated die casting. "Whether the company has integrated die -casting products or technology" and "whether the company is preparing to lay out an integration die -casting" is the problem with the highest volume rate.

Among them, companies such as Tongyu Heavy Industry, Central Plains, Zhubang, and Guansheng shares have not yet involved the application of integrated die -casting technology. Chunxing Seiko said that the company's car integrated die -casting project is currently in preparation and development. Zhongjie Precision said on the interactive platform that the company's wholly -owned subsidiary specializes in the research and development, production and sales of die casting products. At present, there are no orders for customers to provide integrated die -casting products, but the company has the ability to provide such products for downstream customers. Another company said that it will promote the innovation and application of new processes according to market demand and its own situation.

Industry prospects still have uncertainty

The institution is optimistic, is popular with funds, and integrated die casting looks upright. However, the industry's views on the application prospects of integrated die -casting technology are not completely consistent, and many auto industry practitioners and experts have expressed concerns to reporters.

"We are also back and forth in the process of integrating die -casting. It is a bit fluctuating in the middle. This year just caught up with the air outlet. Basically, the same is like this." A share -casting enterprise employee of A shares is a reporter of the Securities Times · E company reporter. It is said that integrated die -casting technology is now relatively cutting -edge, and some customers of new energy vehicles, including traditional brands, try to lay out in this direction. As for how big the market space was later, the employee said "maybe". The staff of another die -casting manufacturer also expressed the same view to reporters: "We are still in the early business reserve stage. At present, there are not a few truly integrated die -casting business in the industry, or the threshold for profitability of integrated die -casting business to achieve profitability. It is relatively high. In the early stage, the purchase equipment is a large investment. The price of the die casting machine is generally high, and it is necessary to personalize the personalized customization of different models. In addition, the integrated die -casting process also requires technical and experience. "

From the perspective of consumers, higher maintenance costs are where integrated die -casting technology is criticized. It's like the mobile phone case is damaged. It is good to change the shell, but the integrated die casting is equivalent to firmly coupled the battery and the shell together. If there is damage, the overall parts should be replaced.

"The integrated die casting process has advantages and disadvantages. Once a traffic accident or system occurs, the maintenance fee will be relatively high. Integrated die -casting technology is relatively large. In terms of economic effects, investment cannot be collected. Especially the integrated die -casting production line is currently in the early stages of the market. The cost of equipment is higher than that of non -integrated models. "Zhang Xiang believes that integrated die castings are not as consistent as consistent as much as consistent as much as consistent than consistent than consistent. Pulling parts, then a large amount of waste may be generated in the quality inspection process, and the advantages of low cost can be played.

"We do die casting by models. Not all models are used by this technology. Some car manufacturers' models are still in the research and development or planning stage, and there is no formal mass production." The development direction of the enterprise itself is closely related. "The development of integrated die -casting technology must be double -sided. What we can do at present is to practice internal skills and welcome the needs from the sales side." Said the aforementioned employees of A -share pressure casting enterprises.

Responsible editor: Luo Xiaoxia

- END -

Zhengzhou: Support Zheng Shang's promotion of chicken, cement and other varieties to speed up listing

Zhongxin Jingwei, July 20th. On the 20th, the Zhengzhou Municipal People's Government issued the Implementation Opinions on Supporting the High -quality Development of the Futures Industry (hereinaf...

Community fun sports will allow residents to enjoy life

In order to create the atmosphere of the health movement of the community and mobi...