The reporter hit the scene: Follow a screw to experience the "smart manufacturing" satellite

Author:Changjiang Daily Time:2022.07.24

The Yangtze River Daily Da Wuhan Client News On July 22, a reporter from the Yangtze River Daily followed the 77th Wuhan Industrial Intelligence Reconstruction Demonstration and Promotion of the "Friday" event to enter the aerospace industry base of Wuhan National Aerospace Industry Base The company's first small satellite smart production line. On the same day, over 20,000 people watched the "smart manufacturing" satellite online.

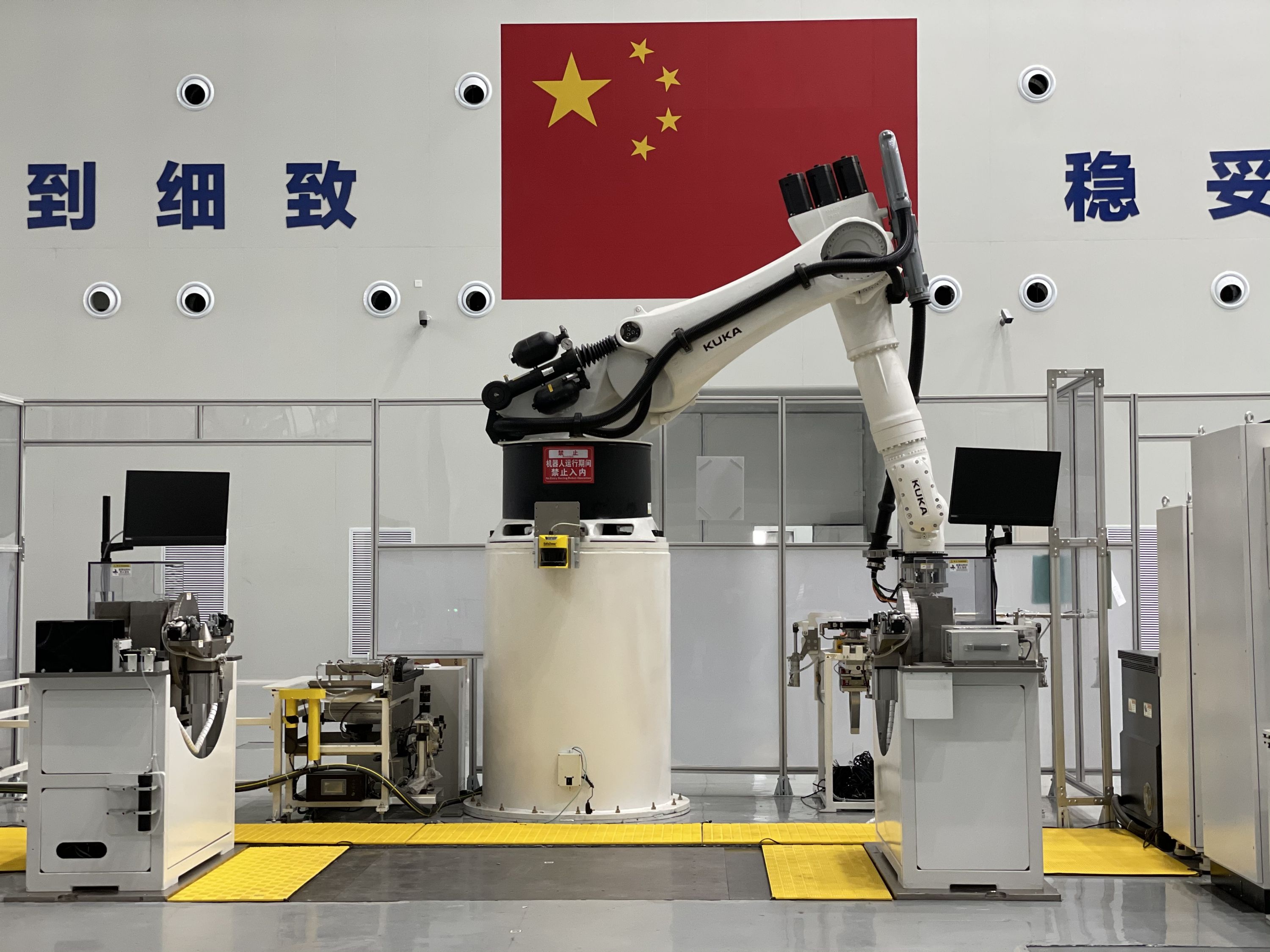

Aerospace Science and Industry Space Engineering Development Co., Ltd. Aerospace Intelligent Manufacturing Center. Drawing

Inside the Aerospace Intelligent Manufacturing Center, two small satellites are being "intelligent". If calculated by the highest capacity, a small satellite is offline every day and a half in this "star -making factory" produced by various types of satellites below 1,000 kg.

The reporter from the Yangtze River Daily first came to the about the seven or eight -level high -level satellite parts library. Here you can store tens of thousands of parts used by satellite manufacturing. Through the intelligent management and control of the warehouse, each screw is coded. From thousands of warehouses, the screws are selected and the stacking machine is sent to the outlet. The screws are delivered to the corresponding amount to the station.

The reporter saw that there was a yellow line on the ground floor of the manufacturing center. Through laser guidance, the AGV car distributed the screw to the smart production line along the yellow line. In the installation link, large -scale robotic arm clamping antenna, communication systems and other components on the 5 stations. At the same time, the lights above have been flashing. Ensure the installation holes of the parts and the installation holes of the cabin can be aligned.

When putting down, the robotic arm should be "weightlifting". "This is much more difficult than catching dolls." Dr. Liu of Aerospace Science and Technology Space Engineering Development Co., Ltd. introduced that this "force" is particularly difficult to grasp. The thickness of the skin and honeycomb cores that require load -bearing are below the sub -millimeter level. To ensure that it will not be too high or too low to smash the cabin and damage the parts, the force sensor of the robotic arm is required to control.

In the end, these parts were perfectly in accurate positions. At this time, the screws that had long been "waiting" here were sent in handy. The operator was responsible for using different specifications of screwdrivers to tighten the screws.

In the assembly session, even "tight screws" do not need artificially. Due to the relative regular, the robotic arm automatically nails, glue tuning, and it is also automatically tightened.

Subsequently, the screws followed the small satellites to complete the entire star electrical testing, thermal control implementation, precision testing, solar wing installation and testing, quality testing, vibration, heat vacuum, leakage, etc., and experienced unpredictable extreme environments. After completing the test and test, small satellites ushered in a new mission and will be launched into space to provide more accurate services for ordinary people.

Through a small screw, you can also see the driving force of "making stars". Dr. Liu introduced that the production line adopts the world's leading cloud manufacturing model, strengthens the sharing and collaboration of resources, and realizes digital integration of upstream and downstream enterprises in the industrial chain. In order to allow components such as screws to meet the needs of batch manufacturing, upstream enterprises continue to upgrade product design according to the production data on the clouds to accelerate the assembly of intelligent production.

(Changjiang Daily reporter Li Jia Liqin Correspondent Wu Jingxuan)

【Edit: Zhao Ke】

For more exciting content, please download the "Da Wuhan" client in the major application markets.

- END -

Newly added +1 in Shanghai, the trajectory involves Huangpu Putuo, and Pudong is listed as a high -risk zone!Preface strengthening immunity start →

At 17:00 on July 4th, the Shanghai Municipal Government News Office organized a pr...

Longquan Town, Longhua District, Haikou, launched the "Action of the Twenty of the 20 CPPCOs" and walked into the promotional activities of the nursing home

In order to further promote the promotion and education of the whole people in the...