Sign 240 million large orders!The industrialization of the 159th Factory of Aerospace Third Hospital has taken an important step [Photos]

Author:Chinese network Time:2022.07.25

China Net News (Correspondent: Deng Yuman Zhao Guowei) Building a 5G additive manufacturing smart factory based on industrial interconnection seems to be high and mysterious, and it seems to be a game of large enterprises. What are the new models of additive manufacturing technology? Can the production line be available for replication and promotion? 30 people, 4 months, signed 240 million orders. This is the story of the Aerospace Adaral Center in the 159th Factory of the Third Hospital of China Aerospace Science and Technology.

Add material manufacturing intelligent factory. Feng Xiaodong Photography

Hire "advanced manufacturing" popularity

Entering the production workshop of the 159 factory Zeng Material Manufacturing Technology Innovation Center, 4 3D printing equipment, rowed into a row, RGV (rail shuttle car) hanging next to the device, grab the processing cylinder through the robotic arm, and place it accurately through RGV to accurately put it into the RGV Printing the device operating table, modern atmosphere comes.

If it is just robotic arm, RGV, and automatic detection, this is no different from automated production lines. But the intelligent manufacturing of additives is obviously different from this.

Factory 159 will work with Unicom to build an exclusive server of marginal clouds to transmit all data to the server. If the data does not get out of the park, all production equipment can be used to control, reduce operators, promote the reduction of the cost of manufacturing products to reduce costs and reduce costs reduction. Increasing efficiency can also protect information security.

"This is our customized production line system that we customize continuous production. It will make a reasonable layout of printing host, cleaning powder system, powder supply system, logistics system, and other supporting auxiliary systems. Through 5G online data collection, online monitoring of the printing process is realized . "Said Zhang Wentao, the person in charge of the 159 factory.

In order to meet the increasingly heavier scientific research and production needs, the additional material production line uses the features of the 5G network "large bandwidth, low latency, high reliability" characteristics, and uses the mobile cylinder mode to achieve continuous production of printing units. , Effectively enhance the comprehensive production capacity of additive manufacturing lines.

With the continuous breakthrough of the entire industry chain of the Zeng Materials Center, the influence and popularity of the 159 factory in the field of aerospace additive manufacturing are becoming more and more wider, and more and more strategic cooperation agreements signed.

Shandong Linyi cooperative enterprises are one of them. When they first came to the 159 factory to make a smart production workshop to visit and communicate, they moved the smart production line of the workshop and watched a variety of precision structured products printed by a full -time printer. Knowing that 3D printing, as a new type of technology, is not comparable to traditional manufacturing, and this advanced manufacturing method can not only expand the development path of the local real estate industry, but also become an important starting point for promoting the transformation and upgrading of manufacturing and high -quality development.

After several rounds of online negotiations, Linyi cooperative enterprises invited 159 plants to visit the local area to help them find advanced manufacturing methods and expand industrial development paths.

Trust stems from doing it first

Only by making achievements can you win trust.

After years of technological precipitation of the 159 factory additive manufacturing center, it has broken through the application technology of the addition of typical structural product additional material manufacturing technology, and has achieved the application of more than 4,000 additive manufacturing products in more than 30 models. , Difficulty, dangerous bottleneck.

In the process of 3D printing and processing, the forming direction or placement of the product will affect the quality of the product. Therefore, quality monitoring and guarantee are the focus of product manufacturers.

"Whoever can control the quality of the product can win." Zhang Wentao said.

In order to cope with quality challenges, the 159 factory Zeng Material Manufacturing Center team spent more thoughts on the breakthrough of the product formation process.

When processing and production of large -sized thin -walled structure products, higher thermal sources (laser) cause severe deformation to expand and shrink the metal. Compared with the original data, the deviation may exceed the acceptable range. In order to solve this problem, Liu Yu, the technical person in charge of the 159 factory additional material manufacturing center, led the team to choose a variety of ways to solve, such as using a shrinking component testing process to verify the process scheme, the process simulation software for multiple iterations, and the equipment on the equipment, as well as the equipment of the equipment The quality of forming is performed online.

Facing the bottleneck problem of the model task cycle and the traditional craftsmanship of new structures, the 159 factory finally ensured the smooth development of the product and the success of the flight test as scheduled.

In addition to ensuring the development of models, their manufacturing technology achievements also have greater "ambitions". In order to occupy the market and contract orders, the 159 factory additive manufacturing center has gradually formed an advantage in manufacturing capabilities. In just one year, a smart manufacturing production workshop has begun to take shape.

"5G+Smart Factory" "Multi -scenario Application of AGV Cars" ... These new things with science fiction are imaginative, and the 159 factory is gradually introducing them into the production process of traditional enterprises.

At present, the Zeng Materials Center has completed the construction of the "5G" additive manufacturing smart platform and the production line automation scheduling system. It has realized real -time collection and monitoring of production and manufacturing data, health management of additive manufacturing equipment, materials and product automation and precision distribution. Large -sized, multi -light beam additive manufacturing equipment is developed by domestic, and the core equipment of the production line of additive manufacturing production line is controlled and controllable.

Linyi cooperative enterprises have seen the technical strength and development determination of the 159 factory addition material manufacturing center. After and after, the two parties began to communicate repeatedly on the construction plan, implementation plan, and production capacity planning plan, and gradually signed a number of strategic cooperation agreements. Their cooperation developed in depth.

Provide a nanny service experience

However, the industrial development path of the 159 factory in the event of Shandong Linyi City's cooperation enterprises will eventually let Shandong's cooperative enterprises dispel concerns. "We need to provide users with production equipment, construction production areas, reasonable arrangement of work areas, and re -deploy process processes and logistics transportation processes." Zhang Wentao introduced.

This is a nanny service experience. 159 Factory Zeng Material Manufacturing Center focuses on the demand for aerospace product manufacturing, and uses independently developed laser constituencies melt equipment as the resource platform to create an overall solution for additive manufacturing. The plan design allows users to take less detours and quickly and efficiently realize the transformation and upgrading of industrial demand.

"Compared with traditional processing and manufacturing methods, our industrial model can reduce the cost of users by about 20%." Zhang Wentao said.

The 159 factory, which is seeking a greater development space, encountered Shandong Linyi cooperative enterprises seeking industrial upgrading. Based on a standardized management system, young management teams, remarkable technical capabilities, long -term foreign cooperation experience, and cultural and price advantages, the 159 factory has become a trusted partner for cooperative companies in Linyi, Shandong.

With the gradual deepening of the knowledge of intelligent manufacturing, the 159 factory not only regards it as its own technical reform. "We hope to build a smart manufacturing demonstration base to drive more local advantageous companies to participate." Zhang Wentao said.

In the future 159 factory additive manufacturing center will also continue to expand the "1+N" regional layout of the additive manufacturing industry, continue to focus on the development needs of the industrialization of additive manufacturing, promote the application of system construction, model innovation, joint innovation, and technological achievements transformation application to form can formable available. Copy and promoted additive manufacturing intelligent factory system solutions to help the upgrade of the manufacturing industry system.

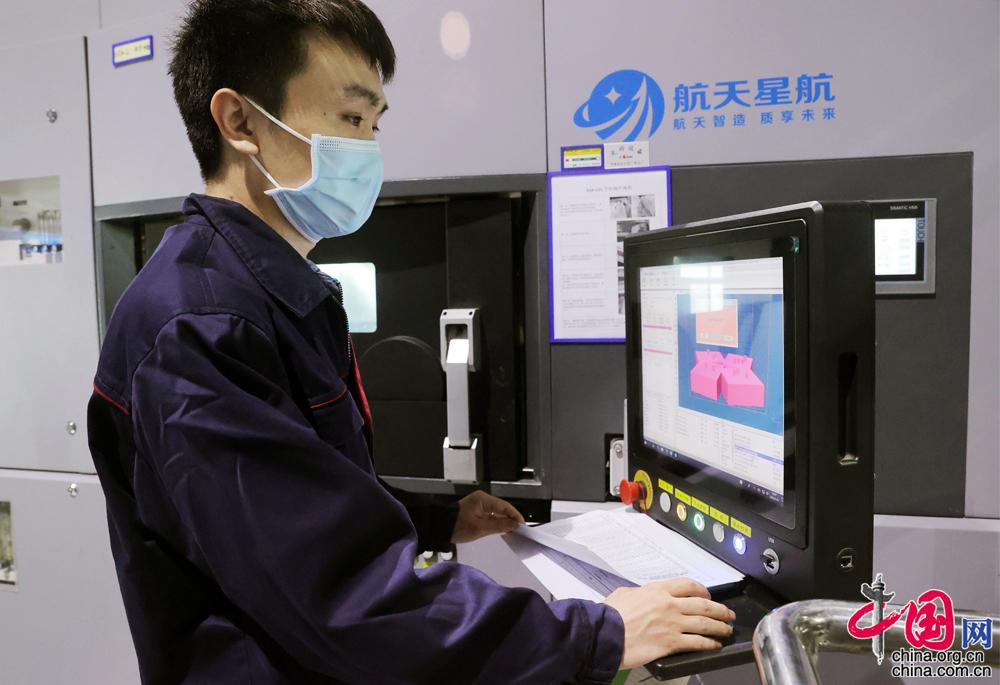

The picture shows technicians analyzing the forming data of additive manufacturing equipment. Feng Xiaodong Photography

The picture shows a platform for manufacturing and controlling the manufacturing and control. Feng Xiaodong Photography

The picture shows the melting equipment of independent development of large -sized eight -light beam laser constituencies. Feng Xiaodong Photography

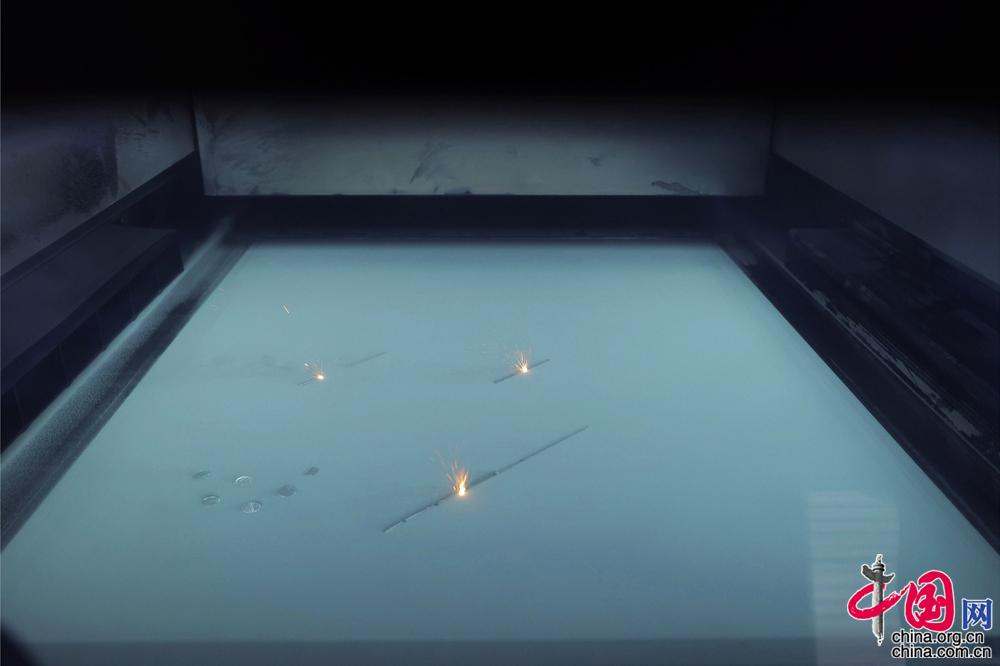

The picture shows the melting process of the laser constituency. Feng Xiaodong Photography

The picture shows the production staff for equipment inspection. Feng Xiaodong Photography

The picture shows the three -dimensional size scanning of additive manufacturing products. Feng Xiaodong Photography

The picture shows technicians conduct special technical research. Feng Xiaodong Photography

The picture shows the operating laser melting deposition equipment. Feng Xiaodong Photography

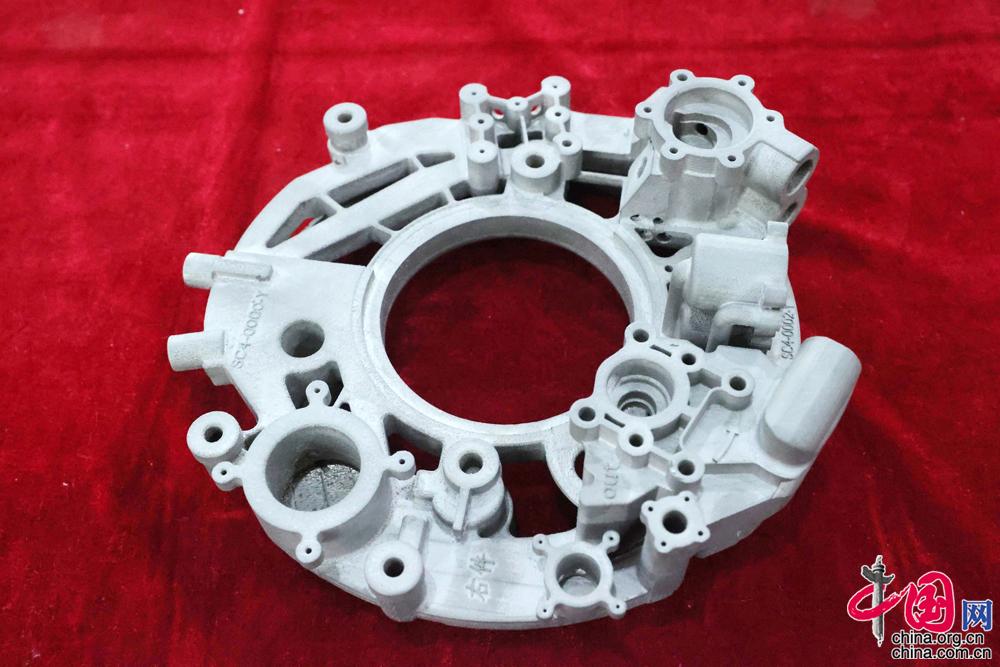

The picture shows the complex integrated formation structure of the additive manufacturing. Feng Xiaodong Photography

The picture shows the manufacturing mobile square system. Feng Xiaodong Photography

- END -

"Wu A Ping" appeared in merit and couplets again?Netizen's original picture: P's

On July 24, the investigation team of the Nanjing Municipal Party Committee and Mu...

Carry out dredging action to restore the road neat and smooth road

Maiji District Rong Media Center (Reporter Bai Li Lu Zhihui) Affected by heavy rai...