Where does the massive construction waste in Beijing go?

Author:China News Weekly Time:2022.07.29

"Local digestion" becomes a new choice

In 2016, at the construction of Universal Studios in Beijing, it was almost stumbled by the problem of garbage.

After the local demolition was completed, the construction party found a huge number of miscellaneous soil underground. These miscellaneous soil contains a large amount of construction waste and domestic garbage. Because of the failure to meet the indicators such as the venue carrying capacity, total settlement and other indicators, their land cannot be directly constructed on it.

Massive garbage

If you want to build a theme park, you must first control the historical issues of the land. Li Shuo is the deputy general manager of Beijing Gongfang Resources Circulation Co., Ltd. (hereinafter referred to as the Beijing Construction Industry Resources Company). This company was established in 2014. Universal Studios's miscellaneous land is the first big project they deal with.

"We planned the soil, we could see waste furniture, and honeycomb coal used for burning stoves." Li Shuo told "China News Weekly" that they also found some pits that concentratedly dumped garbage, "full of mixed domestic garbage."

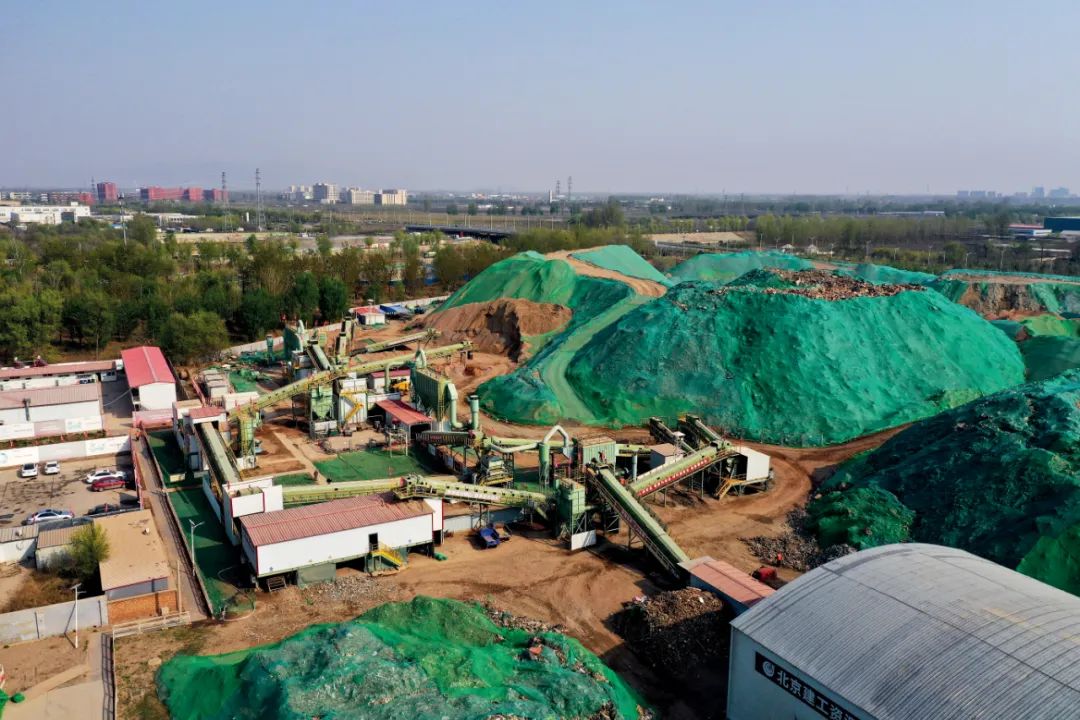

On July 18th, at the Beijing Industry Resources Company, the aggregate piles generated after the disposal of construction waste resource resource disposal. Photography/Reporter Yuan Suwen

The "miscellaneous filled soil" has been cleaned up 2.7 million cubic meters, with nearly 4 million tons, and the empty floor pile of 37 standard football fields needs 10 meters high to be put. Li Shuo said that at the time, if the soil was shipped to the garbage dump, it would take 200,000 vehicles to transport them alone. What's more, the dirty soil is transported away, and it is necessary to return to the good soil.

Li Shuo and his colleagues decided to deal with it in place. They built the production line at the construction site, "locally digestion" and filled the soil. After several screening and processing of machines, they became small granules and regenerative soil. On -site experiments have proved that these regenerative products have reached the standard of recovery.

This is a set of disposal processes that fill the soil as raw materials and resource utilization. In developed countries such as Europe, America, Japan, and South Korea, it is a general practice. At that time, it was still in its infancy in China. After the resource disposal and local backfill, Universal Studios needed to transport the disposal of more than 90 %.

In 2017, Beijing organized a special operation of “Reconstruction and Promotion” throughout the city. This operation included the demolition of illegal buildings and regional markets. As of the first half of 2022, Beijing has demolished more than 200 million square meters in Beijing for five years.

How to deal more environmentally friendly disposal of construction waste? Temporary resource disposal facilities have become new choices. On April 10, 2018, Beijing's "Opinions on Further Strengthening the Comprehensive Utilization of Building Waste Resources" was officially implemented. , Demolition after the task is completed.

The construction waste generated by the dismantling old buildings will be transformed into fine aggregate after resource disposal, and then processed and produced into a new building built in Beijing. They are mostly used to fill the foundation, build a non -inheritance wall, or become the subgrade part below the asphalt road.

These regenerative products were used in large projects such as Universal Studios, Wenyu River Wetland Park, and Liangma River Landscape Project. The regeneration aggregate was also eliminated in hundreds of new parks, creating a continuous hills through mountains and landscapes.

Regeneration

When building the Universal Studios project in 2016, Beijing Construction Industry Resources Co., Ltd. pulled the resource production line of construction waste to the construction site and was demolished after use. This was a pioneering work at the time.

In order to verify whether the recycled aggregate can be used for recovery, Li Shuo and his colleagues opened up the "test field" on the north side of Universal Studios, filling the soil, regenerating soil, vegetarian soil with regenerative soil, and regeneration soil. With 5 kinds of materials for recycled aggregate, vegetarian soil with crushed stones to perform crushing comparison experiments.

After nearly two months of testing, the data shows that the regenerative soil with the regenerative padding pads has the strongest pressure, reaching more than 160 KM. Li Shuo said, "It is equivalent to a square meter of land overlapping and standing four or five adult elephants. The regenerative materials fully meet the requirements of the high standard construction of the Global Theme Park."

The comprehensive production line of construction waste resource disposal displayed by Beijing Construction Industry Company. Photography/Reporter Yuan Suwen

Li Shuo believes that the pressure of regenerative aggregate is better than natural vegetarian soil because the "skeleton effect" is formed inside the soil. He said, "Natural vegetarian soil particles are small, and layers will form layers after stacking layers. There is lack of grasp between layers and layers. Trequently. But after the recycled aggregate mixes into the soil, these hard 'small stones' will bite each other to form a skeleton and form a stable structure. "

After the experiment and demonstration, Universal Studios also became the first large project in Beijing to fill the foundation with recycled aggregate.

In the past five years, Beijing has accelerated the reconstruction of illegal buildings and shantytowns. The relevant person in charge of the Beijing Special Action Office (hereinafter referred to as the Special Office) told China News Weekly that from 2017, in accordance with the unified arrangement of the city, how to deal with the rapid promotion of the construction waste generated by the city It has become a difficult problem. "Considering the protection of the environment, these garbage cannot be simply landed."

According to Li Shuo, before the local resource disposal plan, there are two mainstream resource processing methods in China. One is a fixed processing plant, and the other is the mobile crushing station. These two methods have their own disadvantages. For example, a fixed treatment plant, despite the high processing capacity and high environmental protection standards, can become part of the urban infrastructure after completion, but the construction cycle is long. Consumption for 4 years ". In this way, a large number of construction waste generated in Beijing's rapid promotion of demolition and shed reform operations cannot be dealt with in a timely manner. Another way of dealing -that is, the mobile broken station -is to pull the construction machinery to the construction site, and the oil can crush the construction waste. Although these small machinery are flexible, due to the open -air operation, a large amount of dust will occur during production without any environmental protection measures.

Several products after construction waste disposal. Photography/Reporter Yuan Suwen

"Some even use the gravel machine of mining mines." Li Shuo said that the current construction garbage components are complex, small machinery can only achieve primary screening, and it is difficult to cope with high mixed garbage.

Industry experts said that the construction waste generated in the demolition of violations is also divided into "grades": the first category is slotting soil, which belongs to vegetarian soil. It is valuable and can be sold directly to other projects. After crushing, the strength and hardness are still up to the standard, and it can also be circulated in the market. The most difficult to deal with the third type is that the mixed construction waste containing brick and tiles requires a large investment cost. Today, the dismantling operation advocates the source reduction and refined demolition.

Establishing a temporary production line of "disassembly after use" can strengthen the processing capacity of mixed construction waste. "Each city has a process of large -scale demolition, but it will not always be demolished. Constructing such a production line in areas where the demolition concentrated areas is concentrated. The first temporary disposal facility in the Sunhe Township of Chaoyang was the first temporary disposal facility. This facility did not need to be planned in the early stage. It took only 4 months from the finalization plan to the completion of the operation.

"Local digestion"

The temporary garbage disposal facilities of Sun Hexiang caught up with the "Dongfeng" of the Beijing pilot construction waste on -site resourceization.

At that time, the Beijing Municipal Housing and Construction Commission and the relevant municipal committees organized a large -scale construction enterprise such as Beijing Construction Industry, Shougang, Municipal Road and Bridge, to conduct pilots on -site on -site on -site on -site on -site on -site of demolition, shed reform, and stock waste treatment. In May 2017, it was the first pilot project to be completed in Chaoyang District Sunhe Building Waste Resource Resources.

According to Li Shuo, Sunhe's construction waste resource disposal project is adjacent to Wenyuhe Park, which was under construction at that time. The project consists of a temporary disposal line, a renewable road material production line, and a renewable cement product production line. In the process, more than 90 % of the garbage transformed into recycled aggregate and regenerative building materials, and these regenerative materials built the ecological island, road foundation, waterproof paving and pedestrian trails of the "Beijing Green Ling" Wenyu River Park.

In 2017, Cai Qi, a member of the Political Bureau of the Central Committee, Secretary of the Beijing Municipal Party Committee, and Chen Jining, mayor of Beijing, went to the Sunhe Project of the Sunhe Resources Company of Beijing to build a project to investigate. Green channels should be opened for temporary garbage treatment facilities.

Regenerative bricks made of aggregate. Photography/Reporter Yuan Suwen

Sunhe's construction waste resource disposal project was demolished in 2021. In the 4 years of operation, it allowed more than 1 million tons of construction waste to be "reborn".

After the "rebirth" of construction waste, the government also formulated preferential policies to promote the use of these regenerative products. In the construction industry, because it is still more inclined to use natural materials, under the premise of ensuring construction quality requirements, regenerative building materials are first promoted in government investment projects.

While demolition, nearly 500 pocket parks and urban forests have been built in Beijing. These landscapes have participation in renewable building materials. For example, in the green space of the park in Santai Road, Daxing District, the garden department "piles the mountains and landscape", which causes a continuous slope with regenerative aggregate. Covering about 50 cm of soil on these "hillside" can be planted. When the trails are built in many parks, the road shoulder also uses the blocks made of recycled aggregate.

Beijing requires that renewable products are replaced according to the designated parts of the project. Among them, the government investment engineering requires 10 %. "Standards have been introduced at present, and regenerative building materials can be used to determine the non -inherited heavy parts, fence walls and land hardening of the building."

In April 2018, Beijing's "Opinions on Further Strengthening the Comprehensive Utilization of Building Waste Resources" was officially implemented, requiring the city's districts to adapt to local conditions to build 1 to 2 temporary or semi -fixed construction waste resource utilization facilities. After the task is completed, the relevant departments will speed up the procedures in accordance with the law.

The opinion also clarifies the disposal fee, and the price is required to be clarified in the contract. The contract price is not higher than 150 % of the current standard for disposal costs for construction waste, and it is included in the project demolition cost or project construction cost.

In addition, the opinions have proposed funding support and policy support. The first is to propose the special action funds of "Rectification and Promotion and Promotion" can be used to support the resource disposal and comprehensive utilization expenses of the resource disposal and comprehensive utilization expenses generated by the illegal construction and demolition of various districts.

multiple choices

Relevant departments in Beijing predict that during the "Fourteenth Five -Year Plan" period, the city's construction waste generation will remain high, with an annual increase of more than 130 million tons, of which about 80 % ~ 85 % are abandoned soil. Garbage accounts for 15 % to 20 %. Where should the construction waste go? According to the regulations, Beijing's construction units and construction units shall formulate a treatment (governance) plan to clarify the amount of garbage generation, disposal (or utilization) method, and clearance period, sign a three -party contract with qualified transportation units and disposal places, and go to urban management The department records.

For construction units, there are many options for construction waste. The implementation of the implementation of the construction waste disposal facilities in Beijing is divided into permanent facilities and temporary facilities. Permanent facilities need to obtain planning permits and include the construction of municipal infrastructure projects. By the end of 2021, 4 have been launched in 4, respectively. Chaoyang Gao'antun and Fangshan Liuli River, one in the construction of one, in Haidian Dagura Village, has a design and disposal capacity of 1 million tons per year.

After the regenerative brick was knocked open, the dark red aggregate was revealed. Photography/Reporter Yuan Suwen

For temporary facilities, in accordance with the industry standards of the Ministry of Housing and Urban -Rural Development, the plan to plan and ecological environment departments requires a year of validity. As of the end of 2021, there were 98 temporary resource disposal facilities in Beijing, and the resource disposal capacity was 80 million tons/year.

According to the statistics of the residential construction department, in 2021, a total of 39.8 million tons of construction waste in Beijing's resource -oriented facilities. These construction waste was processed into 12 types of regenerative building materials, with a total of 22.28 million tons and sales of 21.05 million tons.

In fact, the price of resource -based disposal lacks "competitiveness". Although Beijing encourages construction units to settle and directly use the implementation of construction waste, according to government guidance prices, the landfill cost of construction waste is 30 yuan/ton, and the cost of resource disposal is 45 yuan/ton.

In Li Shuo's view, the process of resource resourceization of construction waste is more complicated and the cost is higher. On the assembly line, the construction waste must go through two crushing and multi -level screening, and through the baptism and manual selection of the "vibration wind sorting machine" twice to separate the light matter in the garbage, the last can be returned to the original soil and the regeneration of regeneration. aggregate.

The reason why such multiple processes are involved is because construction waste includes not only soil, brick and tiles, and concrete, but also a large amount of plastic, wooden products and insulation materials, as well as some harmful substances. Only complex comprehensive production lines can be disposed of.

"Cycle" up

Regenerative aggregate is sold in the market, and companies can also gain profit again. However, Li Shuo believes that enterprises still need to charge fees in front -end disposal. "Construction waste is garbage, not resources." He said that in the current demolition and shed reform, the cost of garbage treatment is mostly paid by the government and is called "subsidy", but he does not agree with this approach.

He believes that "the government has management responsibilities for the city's environment. Our enterprise helps cities to solve problems and is similar to cleaning companies, so the disposal costs we charge are essentially not subsidies."

"Actually, if there is no government's support, it is difficult to come to this day." He admits that the current status of garbage disposal enterprises relying on the government's "subsidy" is not good logically, and it is not conducive to the development of the industry. "In fact, if you want to promote the development of the circular economy and environmental protection industry in the future, the most important direction is to pay pollutors." He said that he must find the manufacturer or beneficiary of construction waste, let them bear environmental costs, pay resource -based, Use costs.

If the government is integrating the land, Li Shuo believes that the government can pay the construction waste disposal fee by the government first. In the end, this fee is charged to the beneficiary. The beneficiaries include land developers. If the land is built in a park, the surrounding environment is optimized and the appreciation of nearby commercial areas is promoted, and the cost of waste treatment will be charged from the surrounding developers.

In Li Shuo's view, compared with high land prices, garbage disposal costs are insignificant. "The garbage generated by the construction area per square meter is basically about half tons, and the cost is only 22.5 yuan. If it is replaced with acres, the waste treatment fee per mu is only 10,000 yuan. There is only one point in the land price. "

He believes that finding the generator or beneficiary cost can solve the problem of "subsidies" of government fiscal payment. It not only reduces government pressure, but also gives enterprises sufficient motivation to make the circular economy truly "cycle".

The social acceptance of construction waste regeneration products is not high, and it is also an obstacle to the government's pushing forward by the government. "We carry many other building materials companies that do not need to carry the burden." Li Shuo said that in order to prove the role of recycled aggregate, the company once built a test road in the Sunhe project. 700 tons, regeneration products used in roadbeds and lathes.

Beijing Huairou Datun Construction waste resource disposal project site. Photo/Interviewee provided

Until Sun He's temporary disposal project was demolished, this road was put into use for 40 months. The third party conducted 37 testing and obtained 171 testing data. National standard requirements. This "self -evidence" cost more than one million yuan.

Li Shuo believes that this is because the concept of protecting the environment still needs to be popular. "Although the degree of social acceptance of recycled products has been increased year by year, it has not yet reached universal acceptance. People are still not used to paying for the environment." He said that even if the price of regeneration products is lower than natural products, as a new thing, it is in the market. The top is still not the mainstream, and people still favor natural building materials. Even if the performance of the latter has greatly exceeded the required functions, causing waste of resources.

In fact, in many countries, there are policies that "natural materials are not allowed under a certain standard", that is, projects that can be solved with low -level materials can be used to prohibit the use of higher -end materials to better ensure that renewable enterprises can be better ensured market.

Li Shuo believes that one day, environmental protection will become a "fashionable" matter, or part of the moral evaluation system. "If someone uses regenerative products, it will be respected."

For example, his company recently received an order from the Belgian Embassy in China to make regenerative tiles for new buildings. In the past, orders were required to be smooth on the surface of the yand tiles, which is consistent with natural materials, but the Belgian people proposed to knock on the gray bricks and expose the red granules mixed inside.

"They may think that these uneven and 'exposure' veneer bricks have a beautiful feeling." Li Shuo said.

Send 2022.8.1 Total Issue 1054 "China News Weekly" magazine

Magazine title: Where to go in Beijing's hundreds of millions of tons of construction waste

Reporter: [email protected])

Capture: Wang Lin

- END -

How can administrative law enforcement be able to go down and accept?Experts look like this

Grassroots governance is the cornerstone of the modernization of the national gove...

Football, programming, and drone can learn!Volunteers in Fangzi District, Weifang City help the summer custody of students' holidays more interesting

Qilu.com · Lightning News July 21st. At present, many parents are worried becaus...