The metallurgy is not working on the ground. Why do you go to the sky?There are many advantages in space metallurgy

Author:Scientific belief Time:2022.07.31

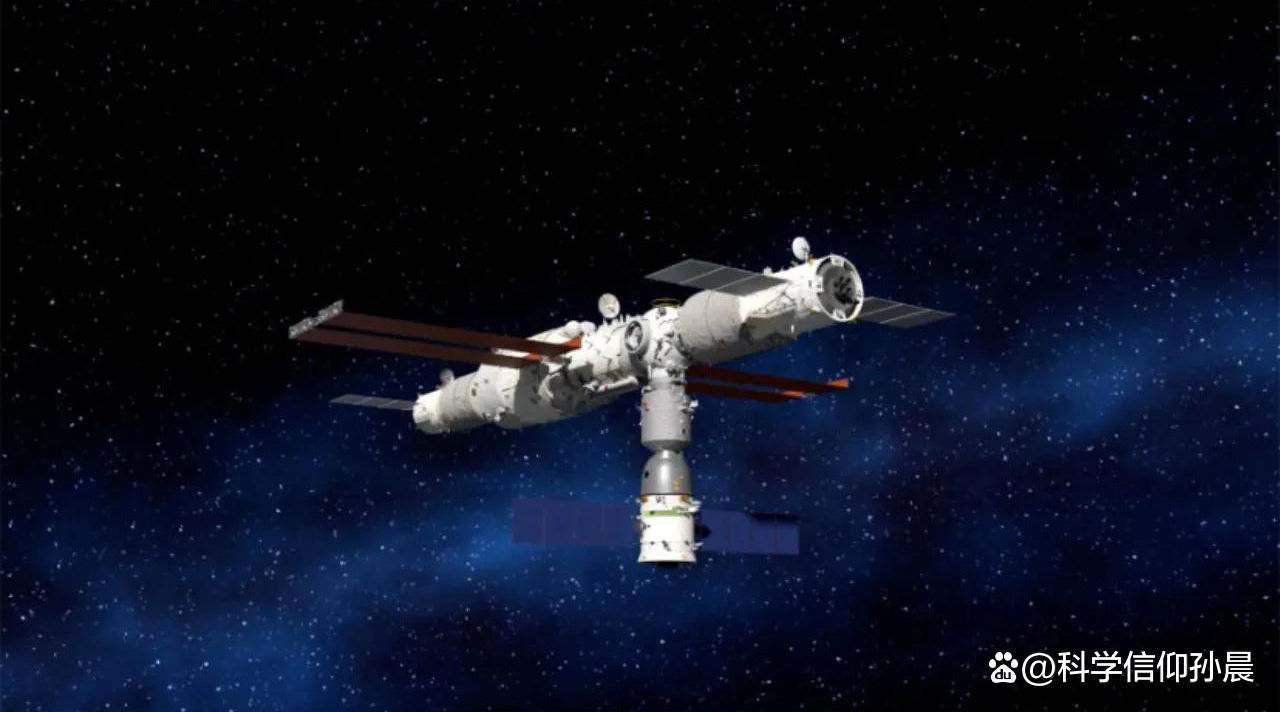

The space station is a space base built by human beings. Reasonable use of space stations can complete many exploration and research that cannot be performed on the earth surface.

Speaking of research experiments in space, the first thing many people think of is to cultivate space seeds. This is indeed a function of the space station, but in space, there are many more important things than cultivating space seeds. Such as space metallurgy. At present, the world's countries attach great importance to space metallurgy experiments, and the earliest space metallurgical experiments can be traced back to 1969. At that time, the Astronauts of the League 6 completed the first micro -gravity metallurgical experiment in human history on the spacecraft. The first manned space -on space was in 1961, which means that the space metallurgy experiments were launched 8 years after the first manned space task, which fully illustrates the importance of space metallurgy experiments.

Has my country launched space metallurgy experiments?

On June 5, 2022, the Shenzhou 14 spacecraft launched a launch, and an important task of the Shenzhou spacecraft was to build a national sky laboratory, and the Sky Lab is composed of two main functional modules. The Members and Dream Timinal Experimental Cels are engaged in micro -gravity experiments, and micro -gravity metallurgical is a very important experimental part in micro -gravity experiments. Metallurgical, we are all very familiar with the process of extracting metal or metal compounds from metal ore, and then processing these extracted metal substances into various metal materials with specific processing methods. Metallurgical is undoubtedly the industrial foundation of a country, but it is not necessary for this work to do it. So what exactly is Sky Metallurgy?

The biggest difference between space and the surface is that gravity is almost ignored, which is difficult to simulate the surface of the earth.

The micro -gravity environment can change the attributes of many substances, so ordinary seeds will turn into space seeds when they turn around in space. Seeds will change in a micro -gravity environment, which is well understood. So how does the micro -gravity environment affect metallurgical? In the micro -gravity environment, metallurgical has a lot of indispensable advantages. The first advantage is reflected in the processing of alloy. The so -called alloy is to integrate two or more different metal substances, and finally form a solid substance with metallic properties. However, the fusion of different metals on the surface of the earth will cause a problem, which is layered.

Different metals have different density. Therefore, when fusion, the density metal will settle, and the low density metal will rise up. Therefore, the distribution of internal metal materials inside the alloy substance is often not uniform.

What happens to the unevenness? The performance of the alloy is not good, but this problem can be easily solved in a micro -gravity environment. Because there is no impact of gravity, the various metals in the alloy liquid will not be layered due to different density. Various metals will be layered. Various metals will It can be fully integrated, so the ultimate alloy performance will be improved. According to previous experiments, the alloy generated in the micro -gravity environment is more than 10 times that of ordinary alloy properties. Another advantage of micro -gravity metallurgy is reflected in the production of foam metal. What is a foam metal? It is a metal material containing a large amount of bubbles inside, which is similar to the plastic foam or brick bricks we usually see.

How to make foam metal?

Simply put, it melts the metal into a liquid and then inflated inside, so that a large amount of bubbles will be generated inside the metal, and then the metal is quickly cooled to solid. These bubbles stay inside the metal. Like the production alloy, the bubbles filled in the metal liquid will also rise due to buoyancy. Therefore, the bubbles inside the foam metal in the final formation are not very uniform, but there is no problem in the micro -gravity environment of space. There is no gravity, so the bubbles will not move in a direction. The bubbles inside the metal liquid can be evenly distributed, so that the bubble metal produced has high quality. In addition, in the micro -gravity environment, the final finished product is more pure without impurities.

Why do metals produced on the earth surface exist in impurities?

Because high -temperature metal liquids always need to be installed. Although the usually used metallurgical container is very stable, it is still inevitable that a small amount of impurities are mixed into the metal liquid. There is almost no gravity in space, which means that the metal solution does not need to be installed with a container. Without container, naturally it will not mix in impurities, which is very important for the production of special materials. Materials are the basis of all industries, and the space metallurgical experiments can greatly promote the development of material engineering. This is why various countries attach great importance to the development of micro -gravity metallurgy and scramble for relevant experiments. It seems that metallurgy in heaven is really more advantageous than metallurgy on the ground.

- END -

3 death penalty!The total number of drugs involved exceeds 566.6 kg

On the morning of June 15th, the first instance of the Nanning Intermediate People...

Maintenance | Flood prevention project (Shandong section) in the lower reaches of the Yellow River officially started

On July 9, the 14th Five -Year Plan flood prevention project (Shandong section) un...