See the crazy "stone" again!It can be seen everywhere in the past, and now it has become a "golden pimple"

Author:Global Times Time:2022.08.28

Recently, benefiting from the rapid development of the photovoltaic and semiconductor industry, a state of short supply called "quartz" is in short supply.

On an open space in Donghai County, Jiangsu Province, some villagers were waving a hoe and dug stones from the soil to put them into a barrel. The villagers said that the stone they dug out was called "quartz", which was mainly sold to the local quartz processing plant. This year's market is good, and the price has doubled.

A villager told reporters that quartz stones are generally 1 to 2 meters underground, and they can turn them out when farming land turns soil. In recent years, as the local environment and land resources are more and more protected, there are fewer and fewer stones that can be dug.

At the door of the factory, the transport truck driving a dedicated heavy station in turn. The truck driver said that these quartz rough are acquired. Recently, the market demand has increased significantly, and it can pull up to 4 vehicles a day. In order to cope with the shortage of quartz stone, Yin Chengqi, a quartz processor, stepped up the purchase of raw materials from the villagers to increase the inventory.

Public information shows that the main ingredients of quartz are silicon dioxide, which has the characteristics of corrosion resistance, high temperature resistance, and high insulation. In recent years, silicon materials based on quartz have developed into an indispensable key material for electronic information, semiconductor, photovoltaic energy, aerospace and other fields.

Playing stone -changing high -tech key materials to simulate the "volcanic burst"

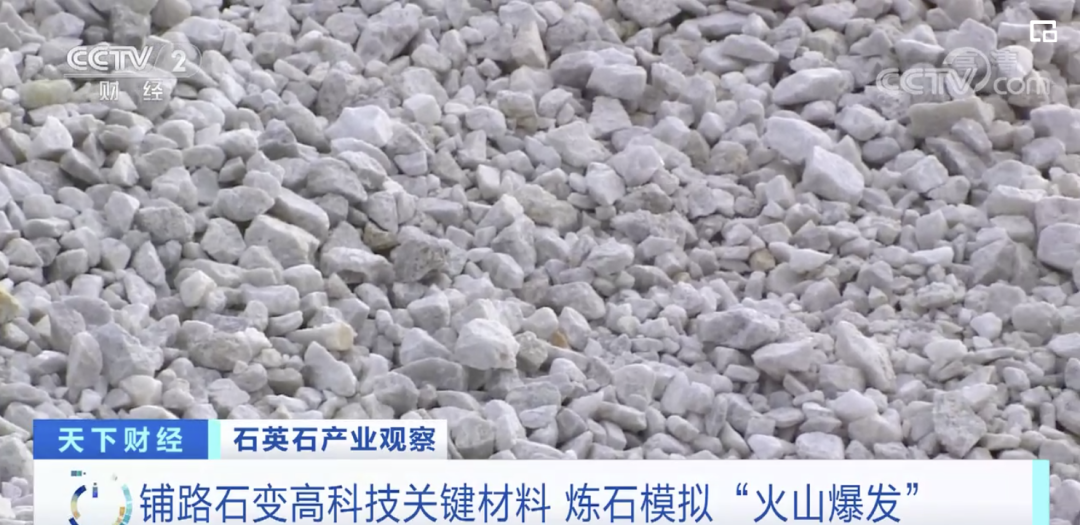

In Donghai County, Jiangsu Province, quartz stone is processed into quartz sand, and according to the content of silicon dioxide, it can be divided into ordinary quartz sand, refined quartz sand, and high pure quartz sand. Usually the content of silicon dioxide is greater than 99.8%. It is called high -pure quartz sand, which has become a raw material for high -tech products.

The reporter came to a quartz rough processing plant in Donghai County, Jiangsu, with 30,000 tons of rough. Quartet is collected from thousands of local households. The color is yellowish, about 500 yuan per ton.

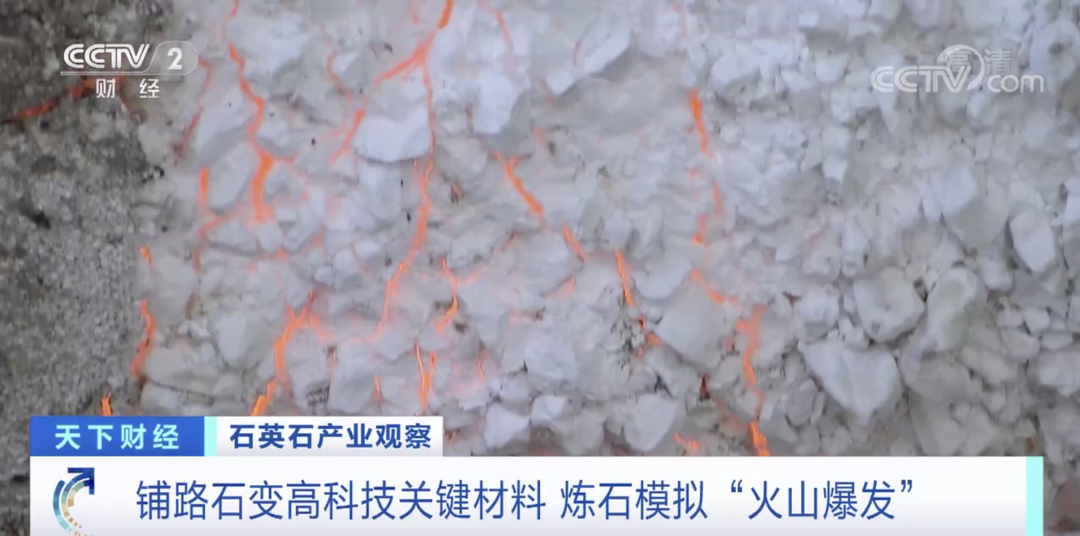

The rough stones after the acid washed in the acid concentration area removed impurities such as yellow skin and mud. The color is white, about 950 yuan per ton. After 8 to 10 hours of smelting these sour rocks, they finally turned into melting quartz.

The staff told reporters that the smelting session simulated the "volcanic outbreak" outdoors, heating the quartz stone to more than 1700 degrees Celsius, and continued to burn for 8-10 hours. broken. In order to further accurate grades, artificial naked eye recognition and selection are also required, and it is broken manually.

The two crushed quartz was as sharp as a "knife". Therefore, in the hot summer, he saw that the staff still wore long -sleeved trousers to prevent "stabbing" in the factory building. At the same time, the reporter learned that the different levels of the quartz are very different. A small black dot can cause completely different uses, and the wages of workers will be different.

After being purified, the higher the pureness of the quartz crystal, the wider the use. The single -crystal quartz pupa in the production of photovoltaic silicon wafers, the inner layer of the inner layer is at least 99.99%, the purity difference is 0.001%, the price per ton is 2 to 3 to 3 10,000 yuan.

According to the local processing household button Ji Qin, he is committed to improving the use of quartz purity as aviation materials, and the highest purity quartz powder can be sold to 300,000 tons. From the 500,000 yuan of business raised in 2012, the total assets have reached 500 million yuan this year.

Lost domestic output in the quartz stone company overtime supplies

The reporter learned in the interview that the peasants in Donghai County, Jiangsu lasted for many years. In order to protect resources and ecological environment, the current mining volume of Donghai County is declining, and there are fewer and fewer quartz stone. As the downstream demand is becoming stronger, enterprises work overtime to ensure supply.

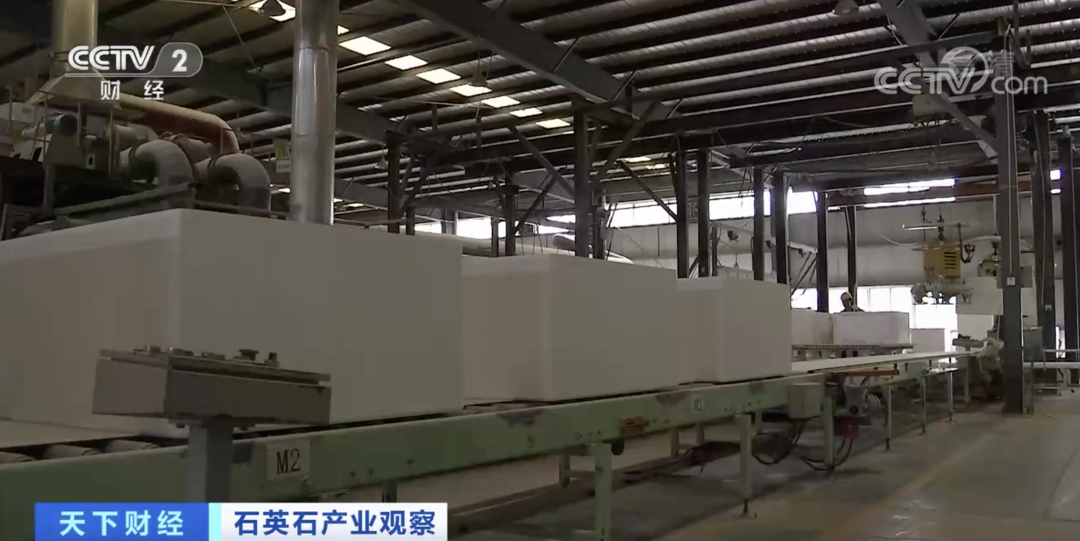

In a factory area of a quartz enterprise in Donghai County, Jiangsu Province, the reporter saw a row of neatly picked imported quartz stone. According to reports, there are fewer and fewer domestic quartz stone output, and more and more imported quartz stones are imported, and some companies have imported stone raw materials in the next five years in advance. Domestic quartz stone is 500 to 1,000 yuan per ton, and the price of imported quartz stones is 2 to 3 times higher than domestic.

The reporter learned that imported quartz stones also need to go through a dozen complex purity processes. Only the silica content reaches more than 99.99%to meet the prerequisite of the domestic single crystal raw materials.

The reporter saw in an enterprise production workshop that more than 4,000 quartz crickets produced overtime will be sold all over the country, and the next step will be used to produce photovoltaic silicon wafers.

As of the end of 2021, the total global silicon wafer production capacity was about 415.1GW, an increase of 67.8%year -on -year. The production capacity of silicon wafers in my country was about 407.2GW, accounting for 98.1%of the world's. This year's photovoltaic development continued to develop at a high speed. In the future, the demand for high -purity quartz is greater.

Source: CCTV Finance

- END -

Notice No. 146, Wuxi Epidemic Prevention and Control

Notice No. 146, Wuxi Epidemic Prevention and ControlAt 6 o'clock on July 13, the city has completed the test of the entire nucleic acid test of the 14th round of regions, with a total of 5.1854 millio...

Four junior high school students in Haikou grab crabs at the seaside, and one was killed by the waves.

Jimu Journalist Zhang HaoOn the afternoon of July 17, four junior high school stud...