Energy -saving carbon reduction performance in the alkaline industry

Author:China Chemical Newspaper Time:2022.06.20

During the National Energy Conservation Publicity Week on June 16, the reporter learned from the National Organization of the National Association of Chloro -alkali Industry Associations online. At the National announcement of the national alkali -roasted energy -saving carbon -saving work meeting, the current chlorine industry in my country has been adjusted through industrial structure and in -depth implementation of energy conservation and emission reduction upgrades. In the transformation, the comprehensive energy consumption of the product of the alkaline unit continued to decline, and the level of equipment ranked at the forefront of the world's advanced level. A large number of backbone enterprises performed well.

Zhang Wenlei, the chairman of the China Chlorohydal Industry Association, pointed out in his speech that in recent years, my country's alkaline production technology and equipment have continued to improve, energy and resources consumption continues to decrease, and comprehensive use of resources has continued to improve. At present, the enterprises have all adopted the ion membrane electrolytic process and equipment, and the membrane pole distance transformation has been completed by more than 90%, which is at a world -class level. With the increasingly mature and continuous expansion of domestic ion membrane products, the production equipment of chlor -alkaline industries has reached 100%, and the level of equipment is at the forefront of the world's advanced level.

In the general manager of Qingdao Gulf Chemistry Co., Ltd. Gao Zijian and the vice president of Binhua Group Co., Ltd., Dong Hongbo said in the sharing of energy -saving and carbon reduction experience of their respective enterprises that enterprises can use advanced process equipment to realize intelligent support control, optimize and detailed operations, strengthen security Training and improvement of employee position skills have achieved very significant results. Specific measures include the implementation of technology transformation and upgrading, optimizing the use of resources, and achieving full use of the residual heat voltage of the alkaline device, the supporting advanced production control system and rectification transformer system, introducing modern information management platforms such as SAP, ERP, OA, and CBS to enhance the core Competitiveness, carry out all employees' innovation and efficiency increase, rationalized suggestions, emergency drills, technical reform measures, etc., improve employee enthusiasm, multi -level excavation of energy conservation potential, and realize innovation and efficiency, energy conservation and emission reduction.

Focusing on the innovation of alkaline equipment innovation and material research and development, Zhang Jian, chairman of Chongqing Po Zhang Intelligent Equipment Co., Ltd., said that the implementation of four -effect evaporation energy saving transformation and upgrading with high concentration of alkalinity and solidine as the main products can effectively save steam consumption. Reduction of carbon emissions; intelligent slices and ion membrane -alkali -molten salt -lowering film evaporation and concentrated integrated technology will also play an important role in promoting energy -saving carbon reduction in the alkali industry and achieving green development.

Liu Yancai, general manager of Beiyuan Chemical Group Corporation of Shaanxi Beiyuan Chemical Group and the leader of the China Chlorohydal Industry Association roasting expert group, shared the company's experience in energy -saving technology transformation and energy management system construction. He pointed out that paddling enterprises should increase technological investment in the fields of low -carbon products, low -carbon technology applications, green hydrogen resources development, and rely on industrial integration to build clean energy+energy storage+chemical+hydrogen energy+zero carbon integration new competition. Power model, reduce carbon emissions of life cycle, and provide new impetus for the high -quality development of enterprises.

The reporter learned that in the context of the "double carbon", the chlor -alkali industry is strengthening green low -carbon technology research, accelerating the transformation of innovation results, and helping energy conservation of carbon reduction in new progress. The use of ionic membrane roasted alkali device to carry out industrial waste salt resource utilization, efficient development and utilization of chloroine hydrogen energy, and the study of electrocatalysts in chlor -alkaline industries and electrocatalysts are becoming a key topic for energy saving and carbon reduction in the industry.

- END -

Wenyuan District, Jiashan Tianning Town, Zhejiang, holds the publicity campaign of "The benefits of garbage classification and multi -environment protection depends on you and me"

In order to actively respond to the call of garbage classification, actively promo...

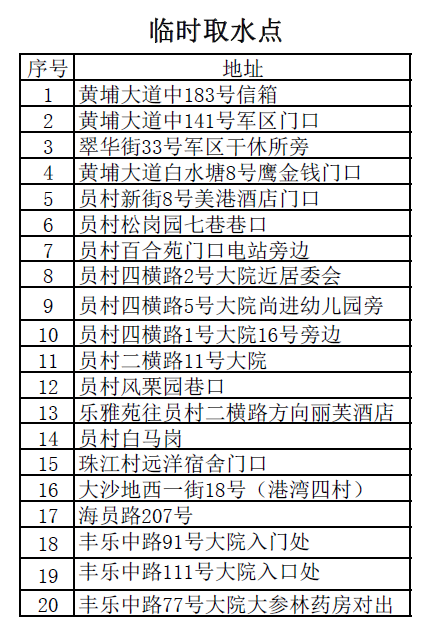

The water pressure in some areas of the original water pipe of the eastern water plant in Guangzhou

The reporter learned from the Guangzhou Water Investment and Water Corporation tha...