Foshan Economic Strategy 丨 Buddhist enterprise executives Africa Top Wilderness

Author:Foshan Daily Time:2022.07.12

In the southwestern part of Kenya, Africa, dozens of kilometers away from the port of Kisu Mu, there is a blue -top plant standing on the green grassland, which is particularly dazzling. This is the sixth factory invested by Foshan Enterprise Keda Manufacturing Co., Ltd. in Africa. It was just put into operation in early June.

At 9 am on June 29, Kenya time, Wang Gang, the director of the Kodak Ceramics (Kenya) factory, sat in the office and connected a video phone from China. On the other side of the phone, in addition to Jiang Hong, deputy general manager of the Kodak African Ceramics Business Management Center in Foshan, there are also several domestic college graduates. They will interview new employees stationed in Africa.

"Are there any siblings?" "Do you like sports?" "Can you drink?" ... Different from interviewers' professional ability, Wang Gang pays more attention to their character. "Working in Africa is relatively boring, and employees who like socialization can stay longer." This is his nine -year work experience in Africa.

In the hearts of many people, Africa is always linked to hunger, disease, and poverty. In recent years, with the rise of a number of Chinese companies such as Chuanyin in Africa, the emergence of Internet celebrities such as Wang Yan, "African Ten Years", has made this distant land in Africa no longer mysterious.

Under the background of the international transfer of the industry, more and more Chinese company executives are sent to Africa. And Wang Gang is one of the hundreds of employees sent to Africa in Kodak, and is also the pioneer for tens of thousands of Chinese companies to explore overseas markets. They are important bridges for China -Africa enterprises to communicate, and they are becoming a witness and witness of Foshan manufacturing from "selling global" to "global creation" historical changes.

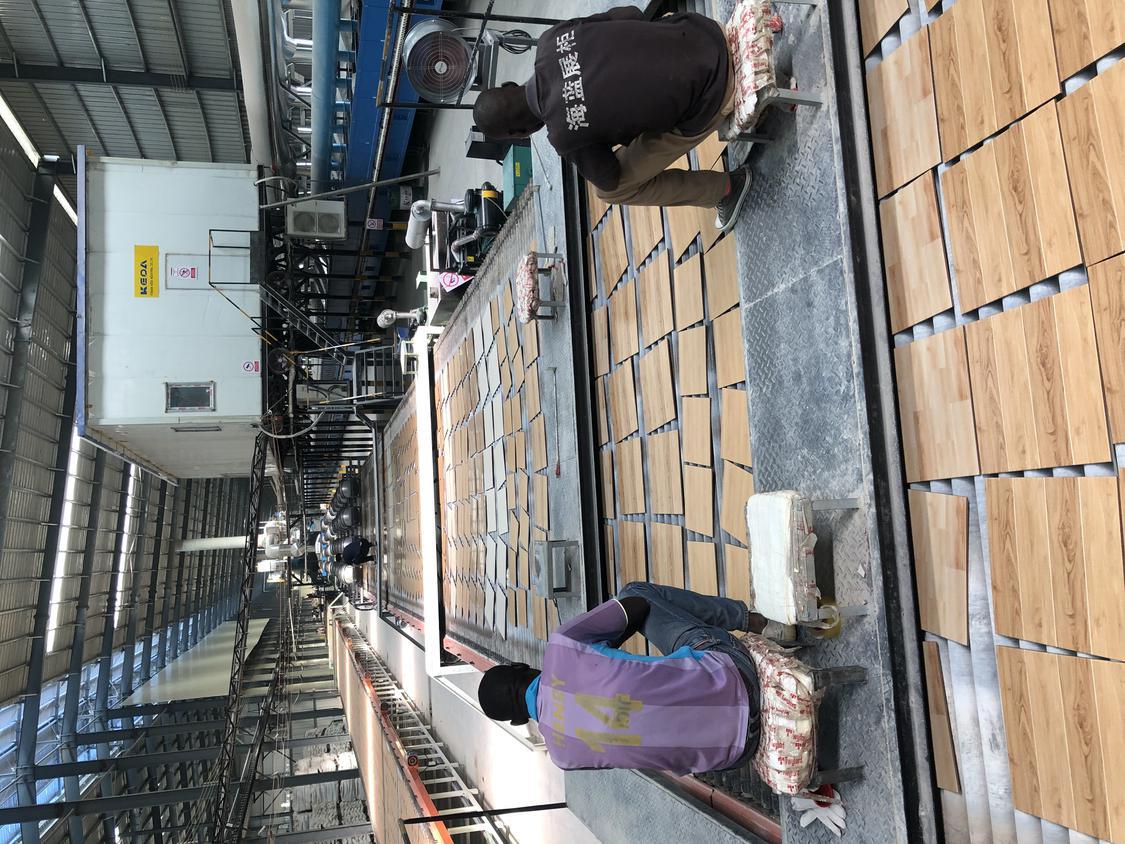

Wang Gang boiled the furnace in the raw material workshop of Kida (Kenya) Kisu Factory.

Find on the new continent to find a new way out

"China is too hot, I want to go back to Africa to avoid the heat." Many people think it is a joke, but Wang Gang knows that this is true.

The southern China was suffering from high temperature and heat. African Kenya, Africa, had only more than 20 degrees Celsius, and the climate was pleasant. When did you look at the migration of animals, where the Chinese food is the most authentic and the best Western food. Talking to reporters about these, Wang Gang came in hand.

In 2013, as an executive of a domestic ceramic enterprise, he took the initiative to apply for the management of local factories in Nigeria, Africa. In nine years in Africa, he has become "African Tong."

However, when it comes to his initial relationship with Africa, there are quite helpless components. In 2012, Chinese ceramic companies frequently encountered anti -dumping "encirclement" in the international market, and at the same time they also suffered huge pressure on domestic energy conservation and emission reduction "vanguard", and the industry entered a stage of reshuffle.

"Every day in the domestic ceramic industry, I want to find a new way out for my career." Holding the mentality of breaking into Africa, Wang Gang set foot on Africa's land.

Wang Gang's choice is to reflect the industrial changes in Chinese manufacturing. Affected by multiple factors such as rising costs and industrial upgrading, in the past ten years, China has opened the fourth round of industries in the world in the world, and some industries have begun to transfer gradients in Southeast Asia, Africa and other regions.

As the second continent in the world, Africa has a total area of 30.2 million square kilometers, and it is also the second continent of the population (about 1.286 billion). In the hearts of many people, Africa is a virgin to be developed and contains huge market opportunities.

As the leader of the domestic ceramic machinery industry, Made of Caida also smelled new business opportunities. In 2016, Kodak Manufacturing has collaborated with the Morida Group, which has been cultivating in Africa for many years, and the two parties have exerted their advantages in manufacturing and sales to jointly build ceramic factories in Africa. The Kenya (Kenya) ceramic factory in Kajia County, Kenya, became the first cooperation project. In the same year, the two sides started the construction of the Ghana ceramic factory.

Going overseas, the process, equipment, and processes are not perfect. In the early stage of factory construction, someone needs to keep an eye on the process. In 2016, Wang Gang came to Ghana from Nigeria and joined the Kodak Ceramics African factory to be responsible for the site selection and construction of the Ghana plant. As a technical guidance of Kodak Manufacturing Headquarters, Jiang Hong was also sent to Ghana. They became the earliest batch of African bulls of African bulls.

Koda (Ghana) ceramic factory site selection.

Ghana has a beautiful natural scenery, but the industrial foundation is extremely weak. Enterprises built factories almost starting from scratch. Water, electricity, natural gas, network, road, etc. must be opened by themselves, and commissioning equipment is also a big challenge.

"We use natural gas to generate electricity. When the equipment is just running, the equipment is still unstable. One day at 10 o'clock in the evening, the power supply suddenly broke. All Chinese employees ran to the factory to check the problem and kept busy until two or three in the morning." Wang Gang recalled the memory. Chinese employees are diligent and responsible. In order to ensure the smooth operation of the production line, they are almost 24 hours online. With the efforts of these "pioneering cows" day and night, in June 2017, the first production line of Caida (Ghana) Ceramics Factory was finally put into production. So far, 5 production lines have been built, and the total production capacity has reached 150,000 square meters. /Day, it became the largest ceramic manufacturing center in West Africa.

Bird's eye -catching (Ghana) ceramic factory.

Localized business requires two -way to go

In 2018, Wang Gang was transferred to Kajiakado County, Kenya, and was responsible for factory management. In June of this year, the Kenyanzi Sumu Factory was officially put into production. The Kodak Ceramics Factory is uninterrupted in 24 hours, and his mobile phone is also turned on for 24 hours.

Kenya is the third long -term life in Africa. Since the signing of the "Belt and Road" cooperation memorandum with China, Kenya's development space has continued to expand. Relevant studies released by the Institute of Policy of Kenya Africa believe that China supports the construction of modern infrastructure projects such as the Kenyan railway, highway, ports, industrial, digital interconnection, to create more positions for the local area and inject vitality to the country's economic development.

In 2016, Keda manufactured the first ceramic factory Keda (Kenya) ceramic factory.

For Wang Gang, whether it is Nigeria, Ghana or Kenya, the biggest challenge is how to do a good job of localized management.

"Although the African economy is relatively backward, some countries pay more attention to education." Wang Gang said, for example, the nationals of Ghana from kindergarten to high school are free admission, while Kenya is a free education from kindergarten to junior high school. It also has basic English communication skills.

Workers in the assembly line have not high requirements for their education. As long as they graduate from junior high school, they can train in English. However, the localization of localization is low, and related vocational education is also lacking. When many workers just enter the factory, they do not even use wrenchs. They need to train handlers and emphasize the management process over and over again.

For professional workers such as machinery and inkjet workers, they need to invest greater costs and more patience. "These types of work have to be skilled at least 1-2 years of training, and in China, we have a lot of ready-made familiar hands." Wang Gang said that for important positions, the company will circulate key cultivation objects in advance as a preparation for promotion in the future as a preparation for promotion in the future. Select personnel to enhance the enthusiasm of local employees. However, important management positions still need support from Chinese employees. Every year, Kodak Manufacturing is sent from China to Africa from China. Every time the graduation season, Wang Gang also enters the peak interview season. "This year, we want to recruit a group of heads of production lines and hope to cultivate them well and become our successor in the future." Wang Gang said.

The cultural differences between China and Africa are large. While African employees are working hard to adapt to the management of modern factories, Wang Gang is also working hard to adapt to the local customs of Africa.

Wang Gang recalled that once a African employee made a mistake when operating the machine, he was about to be injured, and they immediately stopped the employee behavior. Although this was avoided, the employees were injured, and employees were unhappy. "This is because, no matter how urgent the situation is on the scene, you can't talk loudly with African employees, and will be considered disrespectful. So we also pay special attention to this problem in daily management later."

African employees check the bricks of the brick platform for the brick platform of the glazed kiln on the production line.

There are also many precautions in the daily contact with local employees. For example, Africans encounter white and black clothes, but they encounter red clothes in the funeral. If you want to go to the employee's house, they will pay great attention to these pretending etiquette Wang Gang.

In order to increase the exchanges between employees of the two places, Wang Gang will hold entertainment activities every week and every month. For example, after get off work, organize everyone to play table tennis, basketball, or hosted a marathon game to let everyone deepen each other.

After several years of careful operation, the Kodak (Kenya) ceramic factory has also become a benchmark for many African projects. At present, the two factories have a total of 1,500 African employees, and the localization rate exceeds 95%. The flow rate of local employees has also been steadily controlled from 30%in 2017. "Africa's unemployment rate is high. Locals cherish their work after adapting to the work of the factory." Wang Gang said.

Bird's view of Kida (Kenya) ceramic factory Kisu project.

African low -cost front and back

For many companies investing in Africa, Africa's most attractive places also have low costs in addition to the market that is still yet to be developed. However, Wang Gang said frankly that if you only look at the cost of production, the advantages of Africa are not obvious.

"Taking Kenya as an example, the monthly salary of the assembly line workers is 1,000-2000 yuan, but the work efficiency is relatively low. A domestic worker can top 2-3 African workers." Jiang Hong, who has long been responsible for the development of the African market for a long time The cost of employment in Africa is equivalent to domestic third- and fourth -tier cities.

In the production session, ceramic production needs to use raw materials such as clay, long stones, and color glaze. The localized supply rate of the Kenyan plant has exceeded 70%, but core raw materials such as glaze and chemical materials still need to be imported from China. "Africa's ceramic industry chain is far less than domestic." Jiang Hong said.

African employees are packed in graded tiles. What is the cost advantage of the African factory? Freight and import tariffs. Wang Gang said that Africa will impose high tariffs on many imported products. For example, Kodak's main small floor tiles and small wall bricks category, Kenya will impose 35%tariffs. At the same time, affected by the epidemic, since last year, the cost of logistics of sea transportation has soared, and Chinese exporting companies even "one cabinet are difficult to find." These saved costs have become the profit of the enterprise.

The continuous spread of new coronary pneumonia is also profoundly changing the global manufacturing pattern. "All factories in Keda manufacturing in Africa have not stopped working due to the epidemic. Compared with Chinese export companies, we can maintain a more stable supply of supply." Wang Gang said that this production time difference has also made Cardor Manufacturing since 2020, Cada manufactured in Africa in Africa since 2020 in Africa in Africa. The business implementation has increased significantly.

In recent years, the rise of the African real estate industry has also made many Chinese companies eager to invest in Africa. Every month, Wang Gang will receive several batches of Chinese companies representing Chinese companies visiting the factory.

"Today is different." Wang Gang believes that the era of investment opportunities in Africa has passed. Affected by historical reasons, Africa's high -profile energy industries such as hydropower and mines were monopolized by European and American companies. Indian companies followed closely and opened factories and trading companies in various industries. After the reform and opening up, Chinese companies that have gradually entered Africa can only focus on relatively low profits such as the people's livelihood industry, such as building materials and electronic products.

In the context of friendly exchanges between China and Africa, more and more Chinese companies have begun to pour into Africa. As of the end of 2020, China has exceeded 43.4 billion US dollars in Africa, and has invested in more than 50 African countries. China has become the fourth largest source of investment in Africa, and more than 3,500 Chinese companies have rooted in Africa investment. Among them, more than 300 companies from Guangdong.

"Now that Chinese companies enter Africa, they face more competitors." Wang Gang said that at the same time, although Africa has a large population, the local area is rare, and the population is already a big country. More importantly, Africa's per capita income is low, and the gap between the rich and the poor is large. At the same time, it is necessary to deal with a variety of relationships with local governments, workers, etc. These are challenges.

The tiles produced by the Keda (Kenya) factory are mainly small -specified tiles.

However, these new competitors are challenges, but in terms of the manufacture of Kodak, which have already developed first, it is a moat. Made in Kada's 2021 report shows that in 2021, its African building materials business revenue was 2.345 billion yuan, an increase of 31.05%year -on -year; net profit reached 819 million yuan, a year -on -year increase of 100.21%. Kodak created the status of the boss of African ceramic companies.

This year, Kodak Manufacturing not only has the successful operation of the Kenyana Sumu Ceramics Project and the Ghana Ceramics Four Phase IIs. It is also accelerating the construction of the first phase of the Cottda Ceramics, the first phase of the Ghana Sanitary Ware, and the first phase of the Cameroon Ceramics. With the accelerated construction of a group of projects, Jiang Hong will also step into Africa again to start a new round of technical guidance. He will stay in Africa for more than 3 months.

Wang Gangzheng was preparing to return to China. As a child's father, every year, he chose to return to his hometown to accompany his family in the summer vacation. Except for the isolation time, he will enjoy a 30 -day annual leave. This is the annual long vacation of employees and the day he is most looking forward to.

"Africa's ceramic industry is at a booming stage, and I hope to be able to retire in Africa." Wang Gang said.

Text/Foshan Daily Reporter Ruan Fengjuan Picture/Interviewee provided

Video/Foshan Daily reporter Chen Yiwei

- END -

"Pinghu Tongxin · Sunshine Junior Heart" public welfare activity was launched in Wanzhou, Chongqing

(Correspondent: Li Youth) On the morning of June 28, the launching ceremony of the...

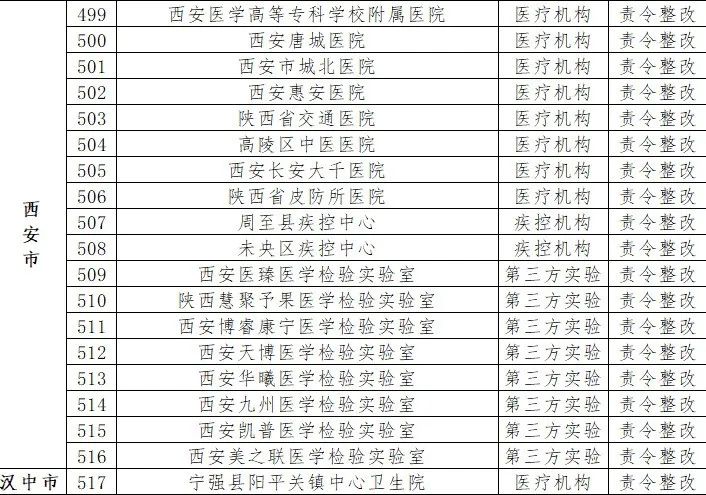

These 19 nucleic acid testing agencies were ordered to rectify!

Recently, Shaanxi Province responded to the new type of coronary virus infection w...