New Era · Railway example 丨 Ru Deyi: The beginning of the heart of the artisan

Author:China Railway Time:2022.07.14

Rudao

● Member of the Communist Party of China, the maintenance workshop at the Shantou Machine Affairs Section (formerly Longchuan Machine Affairs Section) of the China Railway Guangzhou Bureau Group Co., Ltd., has 16 results of personal innovation and invention, led the team to obtain 2 national patents, and has obtained the advanced professional ethics construction of the country. Personal, Guangdong May 1st Labor Medal, Full Road Technical Experts, "Railway Artisans", Nigeria Medal and other honors.

"Taking a line of experts", "The peak of climbing technology is my fun" ... This is a few words that Rudao, the maintenance workshop foreman of the Shantou Paragraph of the China Railway Guangzhou Bureau Group Co., Ltd., often hangs on his mouth. Twenty years, Rudy has concentrated on technical changes and gradually grew from the internal combustion vehicle to the workshop foreman, senior technician, chief technician. Love to think, think hard, and be willing to study ... These traits have made him a world of heaven and earth.

Challenge self -bravery

The Beijing -Guangzhou Line crosses his hometown Shaoguan, and Ru Deyi has deep feelings for the railway since he was a child.

In 2002, Rudeya, who was only 19 years old, graduated from Guangzhou Railway Machinery School and entered the Longchuan Machinery Section responsible for the maintenance of internal combustion locomotives.

From northern Guangdong to the east of Guangdong, Rudao has since entered the new world.

At the beginning of the work, Rudao admired the master's rapid and high -quality to complete his homework. He secretly resolved that he should reach such a high level as soon as possible, so that the internal combustion locomotives he maintained were smoothly and rapidly on the Wanli Railway line to serve the fellows of the father and the people's livelihood.

From then on, Rudao has been studying business knowledge day and night, chasing a master and colleagues at work, holding the script of the script of the principles after get off work, and soaking in machinery and wiring in the evening. Flected. For one year, he achieved the goal of completing the locomotive maintenance alone. "When I first went to work, I read a book a week." Ru Deyi recalled.

In 2003, the Longchuan Airlines section began to undertake the task of repairing internal combustion locomotives. This was a "component" at the time. There were not many units that could be connected.

Ru Deyi's focus on maintenance is also good at seeking breakthroughs and innovation. At that time, the joint regulator of the "heart" of the internal combustion locomotive was 0.01 mm. Rudao was inspired by watchmakers: "The precision accessories of the watch are smaller than sesame seeds, and there are many professional tools. Can I also design a special tool?"

To this end, he studied in the waste compact library of the workshop for 3 months, and tested the physical characteristics of various materials such as iron, plastic, aluminum and other materials. In the end, brass was used as a material to innovate the "special rapid measurement of samples". The measurement time was compressed from 30 minutes to 5 minutes, which greatly improved production efficiency and helped complete the task in the whole section to complete it on time. For a time, the company's self -contained internal combustion locomotive companies around the surrounding area came here to learn and repair technology.

After trying the sweetness of technological innovation, Rudao was angry and actively participated in technological transformation and innovation. In response to the problem of internal combustion locomotive diesel engine injection pump oil leakage oil and card failure in the use of frequent occurrence of locomotives and easily causing fire accidents, he took the lead in tactoring Dongfeng 4 locomotive co -regulator oil motor failure, and proposed the oil injector in the oil pipe joint processing and reform The suggestions of the sealing rubber ring; the "three -research and three trials" maintenance method of the fuel injection pump and the adjustment of the dual installation slot of the tooth barrel processing, which greatly reduced the locomotive failure rate, saving more than 2.8 million yuan in maintenance costs for the unit.

He also kept "charging" himself, and obtained the degree of academic qualifications of Sun Yat -sen University and Southwest Jiaotong University through the self -study examination.

There is no problem with the problem

In 2007, Rudao was promoted to the chief, and he had a heavy responsibility on his shoulders. He changed from a point to a chain, which needed to catch the front, middle and back end.

Combined with daily work experience, Rudyao formulated the team's inspection standards to pass the concept of "planned prevention" to each employee.

Although it is now popular, "planning prevention" was still a forward -looking concept at the time. Ru Deyi mobilized the team to actively implement it and take the lead in action. It was his "master" consciousness that prevented three possible accidents in the future. He treats difficulties as a kind of fun, and he feels very fulfilling after each solving the problem. Ru Deyi always adhered to his original intention, studied hard, and practiced a superb technology. From 2007 to 2011, he ranked among the top three in the professional skills contest for five consecutive years. In 2011, he won the first place and the first place in the Guangzhou Bureau Group Corporation in the technical competition of the Guangzhou Bureau Group Corporation. "Technology is uncertain, find Brother!" Now, when you encounter "difficulty in dysfunction" in your work, the first thing everyone thinks of is him. Not only that, Rudao also has a strong "after -sales consciousness". The driver is driving a locomotive that he is doing himself. He often communicates with the drivers, inquires the experience, and collects feedback from all aspects as a direction for technical research.

In May 2016, the team was meeting. Everyone generally reported that the amount of scrap of the gear of the fuel injection pump was too large, and a large box was piled up, and the maintenance cost increased. This tool is an important accessories for regulating oil. Due to the design of the factory, it can only use a 1/2 circle part at work. The other half is still new at the end of the scrap. He led the team at night to set up a day -to -day research and invented the internal combustion locomotive "dual installation of the fuel jet pump tank to adjust the gear." This design has also been used in half of the new scrap accessories, and the service life doubles. Based on this section of 64 internal combustion locomotives, more than 190,000 yuan can be created per year. In 2021, the invention won the national patent.

Hundred flowers are full of spring and full garden

One flower is not spring, and the flowers are full of spring. Only more technological innovative talents have emerged can the industry be fruitful. Over the years, Ru Deyi has actively shared the teaching experience through the form of "bidding bands" and cultivated a large number of outstanding technical personnel.

In 2019, Longchuan Machinery section founded the Rudao Labor Model Innovation Studio named after his name. His entire chapter system has formed a complete standard management system and workflow of the studio.

The studio focuses on the three key development of "driving equipment, scientific and technological innovation, and labor efficiency", becoming the thoughts and actual positions that lead the technical workers to pursue the spirit of craftsmen. Here is not a matter of seniority, not the length of the work, and the talents. "We have the flight attendant, the reserve group, and the maintenance group. As long as you have a little child, you can come, and you can also come to visit." Ru Deyi said. There are 8 members of the studio, with an average age of 34 and the youngest 27 years old.

From then on, in addition to studying technology, Rudao also led young backbone science and difficulties. The studio not only carried out the spirit of workers' model workers, labor spirit, and craftsmanship education, but also business training such as technicians lectures, locomotives second classrooms, and youth lectures, and gave full play to the "biography" role of the studio team.

Since 2019, the "technician lecture hall" has been taught by the studio 90 times, and the employees have received more than 90%of the training coverage. The business quality has been greatly improved.

In recent years, under the guidance of the studio's demonstration, the Shantou Machinery Section won 29 people in various employee skills competitions of the Guangzhou Bureau Group Corporation, and won 8 people in various employee skills competitions above the road.

Driven by the members of the studio, in 2020, 8 people in this section won the top three results in the Guangzhou Bureau Group Corporation's professional skills competition, 1 person won the 15th place in the Vocational Skills Competition of China National Railway Group Co., Ltd., 4 people won the National Railway Youth Science and Technology Innovation Award.

At present, the studio has carried out 11 technologies and 11 items; 175 problems of locomotive equipment were solved, and nearly 500 other problems were found to be solved; 3,350 employees were trained. In 2019 One of the Guangtailian artisans, 23 technicians and senior technicians in 2020; two technologies have won national practical new patents, and two technologies have won the entire road youth science and technology innovation award. In 2021, the studio was selected by the Guangdong Federation of Trade Unions as the Guangdong Modeling and Craftsman Talent Innovation Studio.

"Organizing me to cultivate me, I will be a good leader." Ru Deyi said.

More than 7,000 days and nights, Tao Liman's world of Rudao inspected more than 10,000 units of locomotives and achieved personal safety production for 20 years. These internal combustion locomotives are galloping on 8 routes such as Beijing, Guangshen, Zhanglong, and Dragon, and played the role of the Hangzhou -Shenzhen -Shenzhen high -speed rail, the Meishan Railway and the Wanhui Intercity Railway. Essence

"Innovation studio strives to apply for a national patent every year." This is Rudy's plan for future.

On the Dongjiang River not far away, the Zhanglong Railway and the construction of the Meilong high -speed rail in construction are "Shuanglong Cross the River". East of Guangdong Tielong Flying, playing the notes of the new era. Ru Deyi took the results of technological innovation to participate in the dialogue of this time. In the new era and new starting point, he will use technology to light up a more efficient and beautiful tomorrow!

Twenty years of persistence

Ru Deyi knocked on the door of innovation with wisdom

Pour the flower of technical reform with hard work

Use rigorous and solid security wall

Book of youth with dedication

Flowers with technological innovation

Blooming on the railway line

Supply: "People's Railway" Newspaper Co., Ltd. Guangdong Reporter Station (Guangzhou Bureau Group Company Rong Media Center)

Wen Tu: He Tingzhao Liu Qiu'an Video: Luo Qun Lin Hao

Edit: Lin Feiyi

- END -

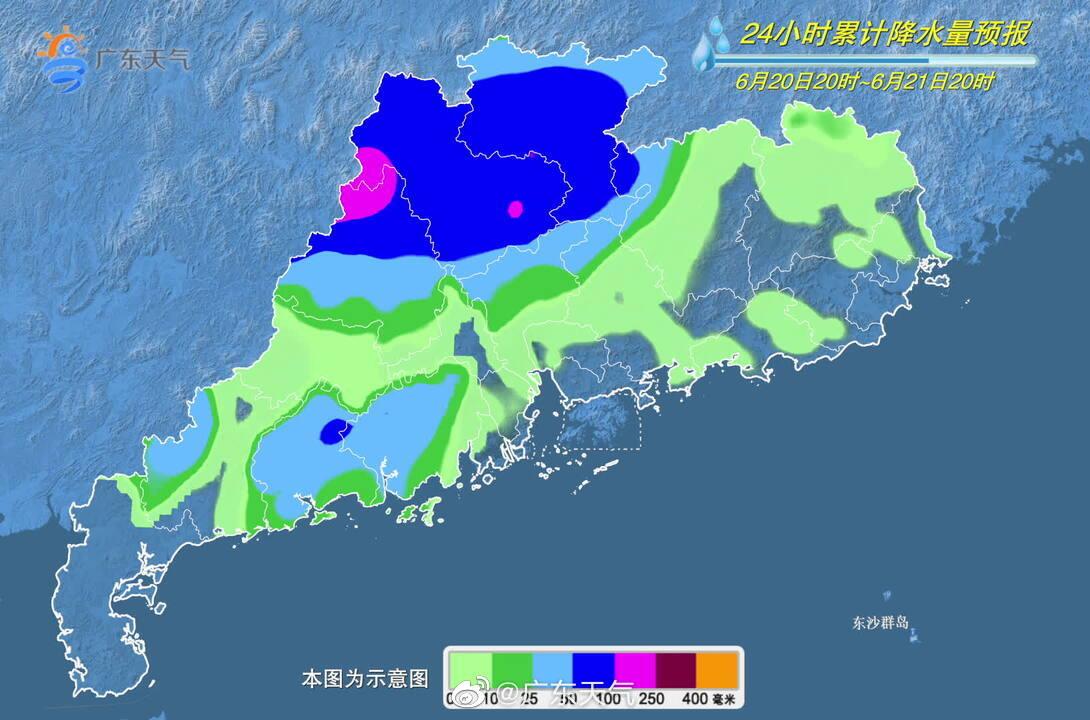

"Summer Solstice" Day "Dragon Boat Water" may still "Lai" northern Guangdong.

Text/Yangcheng Evening News all -media reporter Liang Yantao Correspondent Liang J...

Build a "anti -external break" security network

Insufficient safety distance between excavators and electricity lines, please stop construction immediately! On July 13, the operation and maintenance personnel of the Guozhou County Power Supply Co