In the post -epidemic era, the "elephant" of industrial digitalization is trying to find a way out

Author:Shi Tianhao Time:2022.08.06

The economic recovery of the post -epidemic era allows industrial enterprises to realize the significance of digital transformation to sustainable production and resistance risks, and further accelerate the pace of industrial digital transformation.

At the end of July, the Fourth Global Industrial Internet Conference and Industrial Industry Digital Transformation Annual Conference were held in Zhejiang. The conference was based on the theme of "accelerating industrial digital transformation and promoting economic stability". question. As an authoritative industry summit with high specifications and sufficient gold content and influence in the industrial Internet domain, nearly 1,000 industry application cases were collected at the meeting, and 100 outstanding application cases and top ten typical application cases of the year were selected according to the segmented industry. Essence

From the above data, the excellent cases of digital transformation in industrial enterprises have sprung up like rain. It can be seen that in recent years, the Chinese manufacturing industry has vigorously transformed and upgraded to digitalization and intelligence.

As of the end of June 2022, the Industrial Internet Application has covered 45 categories of national economic categories, with industrial scale exceeding trillion yuan. With the influence of digitalization and intelligence, industrial enterprises have gradually switched to data -driven all businesses. Like the Digital Manufacturing and Globalization 4.0 demonstrator of the Lighthouse Factory (the World Economic Forum and the McKinsey Consulting Company) in China The production system improves production efficiency, and also provides mature digital manufacturing solutions to the outside.

The crisis brought by the epidemic has continuously spawned new technologies, new models, and new industries, reshaping the industrial digital transformation standard system, or the comprehensive impact of the post -epidemic era on the development of industrial development. Industrial digitization is destined to move forward with weight, trying to explore the way out to find victory.

In the future, the global economy competition will focus on productivity efficiency, scientific research strength and development quality. Industrial digitalization is obviously the only way out.

New infrastructure help, attack industry 4.0

Without the landing of new infrastructure, there is no industrial digitalization. Like the development of the Internet, the advancement of industrial infrastructure directly determines the rate of upstream development.

The narrow "new infrastructure" mainly refers to the new infrastructure represented by 5G, artificial intelligence, industrial Internet, and the Internet of Things, which is essentially the infrastructure of digital information. The "new infrastructure" in the broad sense mainly includes seven major areas including 5G infrastructure, UHV, intercity high -speed railway and intercity rail transit, new energy vehicle charging piles, big data centers, artificial intelligence, and industrial Internet. Traffic, numbers and other key industries such as social livelihood.

Relatively speaking, the latter is more widely covered and easy to obtain social identity. Whether it is a narrow or broad definition, new infrastructure is a powerful starting point for the digital transformation of enterprises.

First, it provides the ability of digital and intelligent "accumulating trees";

During the epidemic, the construction project of the Vulcan Mountain Lei Shenshan Hospital, which raced with time, allowed the world to witness China's strong infrastructure capabilities. The digital technologies of their perfect industrial equipment, logistics transportation, and communication networks have set up the best practical cases for the entire infrastructure industry. It also fully shows the world the fulfillment of China's infrastructure to fully apply digital innovation ideas to solve the needs that the old technology cannot achieve, and improve the ability and efficiency of enterprises in the field of product design and research and development.

Without the popularization of new infrastructure mentioned above, industrial enterprises are very scary to build industrial 4.0 capabilities. Because of the vigorous promotion of information digital infrastructure, enterprises can "set up blocks" according to their needs, and continue to digitize and intelligence with the changes in the development stage.

Second, the comprehensive application of new generation of information technology such as 5G and AI;

my country has introduced a number of policies to support the integration and development and application of 5G and the Industrial Internet. The 5G capacity of 5G in the new infrastructure has the strong empowerment capabilities of industrial digitalization, allowing them to play the economic benefits of the initial results in various professional parks in China. The three major operators and Internet technology companies represented by Huawei and Tencent have helped the Industrial Park, and Logistics parks and other parks have a digital transformation, creating the core integrated solutions for the construction of 5G smart parks. The use of 5G technology has landed in the park in the park, the intelligent security system, the Internet of Things management, and information technology are used.

The traditional Internet is more about information interaction on demand and server, ordering and delivery in the field of e -commerce, reading and machine recommendations in the content field. The end of industrial digital tentacles is countless production equipment, industrial robots and assembly lines. A new generation of information technology such as 5G, cloud computing, artificial intelligence, etc. are the basis of digitalization of the industry. The foundation of the Industrial Internet has laid the foundation, and another reason is the development of marginal computing. Without their support, industrial digitalization will not be able to talk about it.

As the name suggests, the new infrastructure is the new infrastructure construction of a digital society. It is precisely because of the extensive advancement of new infrastructure that the industrial digitization is that there is a path to go. As of the end of 2021, the number of industrial small and medium -sized enterprises above designated size reached 400,000, operating income exceeded 75 trillion yuan, and the total profit reached 4.7 trillion yuan.

Due to the factors such as the release of the manufacturing industry and the release of demographic dividends in Southeast Asia, China's industry is facing the torrent of global competition, and digitalization is the only direction of a breakthrough.

Industrial brain, from system to wisdom

Compared with developed countries, my country's development of "Industry 4.0" still has visible shortcomings and difficulties. For example, Germany is now developing to 4.0, moving from automation to network informatization, and then see the "advanced manufacturing leadership strategy" in the United States, Germany " The National Industrial Strategy 2030 "and Japan's" Social 5.0 "and other development strategies with the core of regaining manufacturing as the core are the main starting point of intelligent manufacturing, and my country's machinery manufacturing industry is still between industrial 2.0-30. Moreover, the total number of domestic labor ages has declined year by year, and it is undoubtedly worse for companies that have insufficient labor force. Seeing that global technology and industrial competition is more fierce, intelligent manufacturing needs to achieve all aspects of the product, manufacturing, and service system integration of the entire life cycle of products, and the integration of the manufacturing system of the entire life cycle. The transformation of smart devices such as NCC machine tools, robots, 3D printing, and AGV cars in emerging industries has become increasingly urgent.

The transformation from manufacturing in China to China's intelligent manufacturing, trying to seize a new round of competitive highs in the global manufacturing industry. Intelligent manufacturing with industrial robots as its core will become the main path of the digital transformation of manufacturing. Observation data shows that China's intelligent manufacturing equipment market has more than 50%of the satisfaction rate, and the main business income of more than 1 billion yuan has more than 40 suppliers.

With the introduction of a series of favorable policies, Chinese enterprises have also explored for smart manufacturing system solutions. From the intelligent supplementary spray of robotics, the internal intelligent laser welding, intelligent packaging ... to the Heier Zhijia Zhengzhou water heater interconnection factory, the intelligent and digital industrial Internet ecosystem of the Kaos platform empower.

Especially the Haier Zhijia, as one of the leading sheeps in the home appliance industry, ranked first among the latest Chinese intelligent manufacturing 50 companies released in 2021. It has been accelerating manufacturing innovation within a few years. In terms of intelligent manufacturing, Haier Zhijia Family 17 interconnected factories have been built, two of which have been selected as lighthouse factories. They all present the development trend of my country's industry from the system to wisdom.

Overall, the transit wisdom is divided into three levels of changes:

First of all, generally manufacture to intelligent manufacturing; traditional industrial fields rely on manpower. In the era of Industry 4.0, industrial enterprises will widely apply robots, intelligent machines and automated devices. On the one hand The manufacturing quality and production efficiency far exceed the traditional method.

Secondly, the production of single enterprises to ecological intelligence production; compared with the service industry, various fields of industry emphasize ecological synergy. In the past, industrial production showed a loose structure. The lack of information between upstream and downstream enterprises in ecological chains often had an effective interoperability of information. The phenomenon of mismatch with demand. In the era of industrial 4.0, high degree of digitalization between manufacturers, providing the foundation for the high coordination of upstream and downstream ecological chain companies, making efficiency production and green production possible.

Finally, the C2M model with a huge potential; the biggest disadvantage of industrialized goods is the personalized loss brought by high standardization. In the past, due to the huge information gap between the consumer and the production side, there was a delay matching in demand and production. The C2M model (user -based manufacturing) brought by Industry 4.0 is connected to the consumer Internet, industrial Internet and industrial Internet. Based on the flexibility and data -driven of intelligent production equipment, it also provides possibilities for this customized production. Taking a car as an example, now when we buy a car, we can only choose in several models produced by the manufacturer. In the future, we can directly "select" the desired configuration in the 4S shop, and then the car factory will directly produce them. This will greatly improve The relationship between demand and production.

In the past, the development of industrialization was a combination of the scale effect of standard production and the vigorous social needs. In the digital industry era, trying to find a perfect entry point between production costs and personalized needs. Data and computing power are "optimizing" our world. The digital industry brings not only production efficiency, green production, and high -quality development. Faid, it also contains more possibilities.

Elephant moves forward, high -quality development is long and far away

The rapid development of any industry requires a rule as the general program.

The Industrial Internet Conference also released my country's first "industrial digital transformation evaluation system", which marks a scientific and objective evaluation system in industrial digital transformation. The evaluation system includes the first -level indicators of technology, business, and management, 15 second -level indicators, and 33 third -level indicators. Through the dynamic evaluation index, you can intuitively obtain the basic level and growth rate of digital transformation of the nation's manufacturing industry. Provide a reference for the formulation of high -quality development policies for industrial digitalization.

How to define the high -quality development of industry? In terms of the focus of the development of the Internet, the intelligent flow of industrial data with fine computing power is the main direction, with high collaboration of industrial enterprises and various needs on the industrial Internet, and the down -to -stable closed -loop service generates industrial industrial The first line of data production realizes the comprehensive upgrade of industrial enterprises from all levels of management, operation, production, logistics, and sales. The development of efficient and scientific development pursues quality rather than blindly catching up.

In addition to policy support, through the construction of fund support to increase the digital transformation of the industrial field, major domestic digital solutions have provided new integrated information technologies for the digital transformation of industrial digitalization in the post -epidemic era from deep to realistic industrial digital intelligence applications. With operational technical capabilities. Like multi-party Unicom's China Soft International and Shen Kaihong's new "Cloud-Pipe-Duan" full-stack service, which can pave the way for industrial digital management management, the one-stop industrial product procurement platform under Jingdong-Jingdong Industrial Products With a complete supply chain cooperation relationship, in -depth cooperation has also been established with the top 100 Chinese machinery industry companies, providing enterprises with huge optimization potential through forward -looking support.

After seeing the top of the consumer Internet, it means that my consumer trading chain has entered a mature stage. Everyone is connected to the Internet, and things are connected to the Internet. Through the Internet, everyone can buy the products they want, and each product can reach its service object. Global Digital Economy White Paper (2022) ". The white paper shows that in 2021, the value added of the digital economy in 47 major countries around the world reached US $ 38.1 trillion, of which the Chinese digital economy reached 7.1 trillion US dollars, accounting for 18.5%of the total amount of 47 countries, second only to the United States and place Line second in the world.

The prosperity of the demand matching end has been born with a large series of Internet giants such as Alibaba, Tencent, Baidu, JD.com, Meituan, Pinduoduo. They gathered the most delicate talents in the domestic information industry. The Internet of Things has deep accumulation. In the tide of industrial digitalization, the digital transformation needs of countless enterprises have become the blue ocean space for their next stage.

In 2018, Ali announced that he would comprehensively enter the area of all things; in the same year, Tencent conducted organizational adjustment (that is, the "930" reform), and the "Industrial Internet" first mentioned the focus of the case. Three years later, Tencent announced its strategic upgrade of strategic upgrade It proposes to "take root in the consumer Internet, embrace the industrial Internet, and promote sustainable social value innovation"; Baidu regards AI as the future.

Needless to say, these moving elephants are not lonely, which has also become one of the good news in the future of industrial digitalization.

at last

According to the analysis of the digital transformation of industrial enterprises by E-Works Research, it is found that less than 14%of enterprises that can enter the stage of deepening or innovation, and 25.4%of companies are still in the infancy that has not yet been planned, and has not yet moved towards digitalization.

Thinking about the future industry, digitalization is an opportunity for industry, but it does not mean that all companies can get bonus. In response to the uncertainty of changes in the internal and external environment, industrial enterprises have difficulty in digital transformation project funds, new digital technologies, and new digital technologies, and corporate organizations and talents are all difficulties that need to overcome one by one on the road of digital transformation of enterprises. The bright road is still moving forward.

- END -

Daily discussion of gold | Raising interest rate hikes and pressure, gold bulls still have not succumbed to

Guest: Gold Investment Analyst Zhang BoOn the week of June 13, the spot gold price once again experienced the roller coaster, hitting a maximum of $ 1880/ounce, a minimum of US $ 1805/ounce, and recei

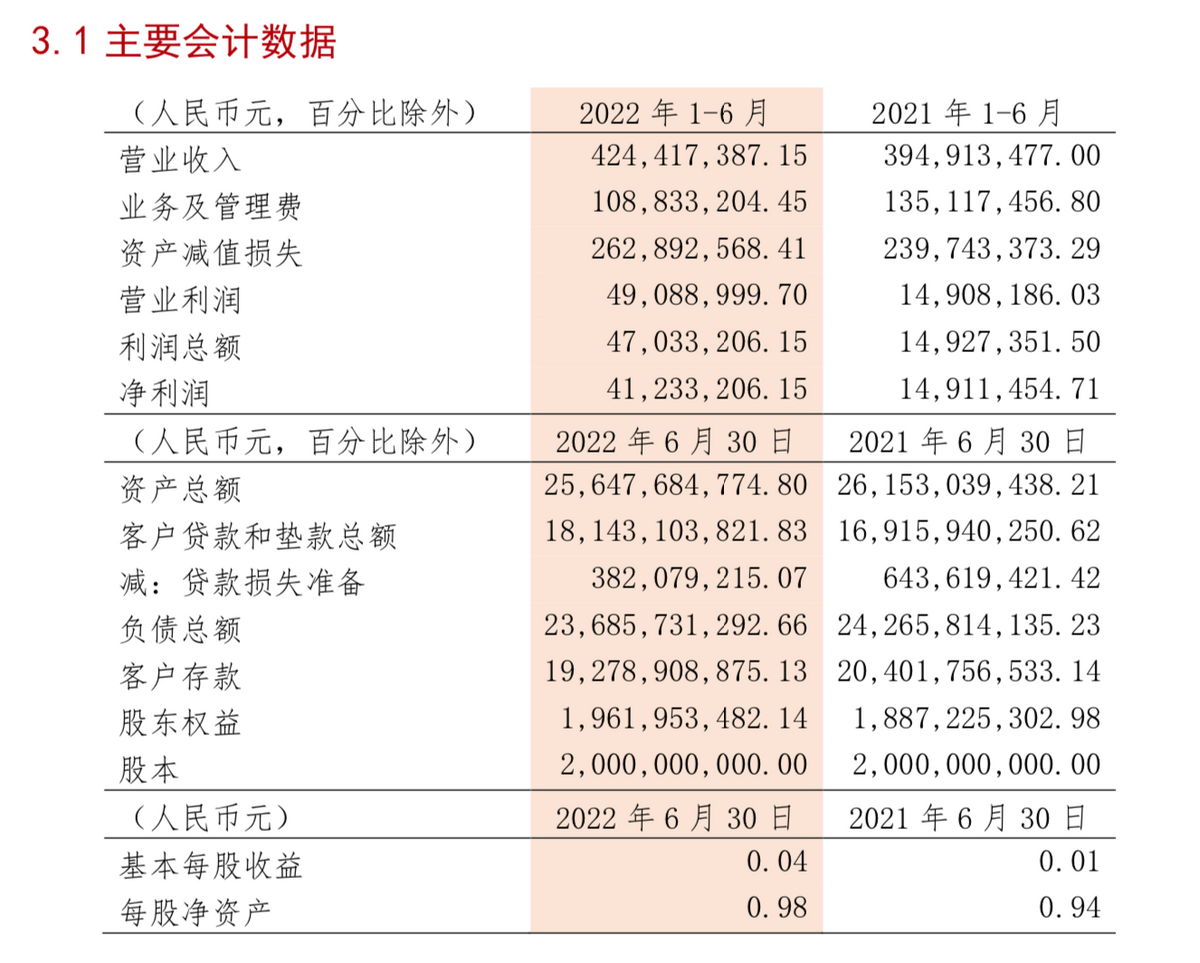

The first private bank's half -year report was released: Liaoning's revitalization bank's assets shrink, net profit increased by 176.52% year -on -year

Produced | WEMONEY Research RoomWen | Liu ShuangxiaThe first semi -annual report of ...