Striving for first -class and striving for the only one | Tianyi Machinery: Technical empowerment of prefabricated building equipment industry leaders

Author:Jining News Network Time:2022.08.16

Editor's note: Keep in mind that the instructions are entrusted to the front, and the mission will start a new game. From August to September, Jining Radio and Television launched the "Walking in front of the new bureau, striving for first-class and striving for the first-in-one-the 20th National Congress of the Party" Jining 14 counties and urban areas of the city. The forms of experience, marching reports, and panoramic display, etc., fully demonstrate the positive progress and achievements of counties and cities in the implementation of the "Nine Congress Strategy" in various counties and cities.

Jining News Network August 16th. Recently, in the modern factory workshop of Shandong Tianyi Machinery Co., Ltd. in Yanzhou District, Jining City, the machine roars, rows of intelligent machinery and equipment operate in an organized manner, colorful and different robots, robots in different sizes, The synonym for intelligent manufacturing has changed the traditional construction industry.

"The major transformation of the traditional construction industry is largely benefited from the construction equipment called 'prefabricated'." When the reporter saw Chen Depeng, the chief engineer of Tianyi Machinery, he was leading the team to conduct a trial production of Xinjiang -free template production projects in Xinjiang After the details of the details, Chen Depeng pointed to the machine running in the workshop and told reporters that during the four -month construction period, from the discussion plan, mechanical personnel building, electrical engineers to make circuit diagrams, to work, delivery, installation, debugging, acceptance, acceptance, acceptance, acceptance, acceptance, acceptance, acceptance, acceptance, acceptance, acceptance, acceptance, acceptance, acceptance, acceptance, acceptance. Only a production line project for prefabricated building equipment was completed.

Technical empowerment, "Little Giant" leads the domestic prefabricated building equipment industry

"This is an automatic fabric machine, which is an advanced level in China. It can be automatically fabricated according to the drawings from the design institute. The quantitative is accurate and the location is accurate ... This is the wall board installation equipment, which is suitable for on -site installation. Don't look at it small, but it is very popular with the installation company. "Chen Depeng introduced various equipment to reporters to various equipment in the workshop and their" housekeeping skills ".

In 1998, it was established with the construction of the building wall board. Since the promotion of prefabricated buildings, enterprises have been actively invested in R & D costs, and continuously attracting high -level technical talents to join the industry to deeply cultivate.

Since the prefabricated building equipment has been completed in the factory, only the finished product is needed at the construction site. This production model makes the original handmade production converted into mechanical production, the construction site production turns to the factory production, and the on -site production will be converted to the on -site production. On -site assembly, not only the on -site construction efficiency has improved, the safety and environmental protection factor have also improved, and the development of the prefabricated building equipment industry has a unique advantage.

Chen Depeng recalled that there was no robotic operation. Welding a molding table requires about seven people, and one day can be welded in one day. Today, the investment and use of welding robots greatly saves labor costs and improved production efficiency. In 2000, Tianyi Machinery began to transform into assembly building equipment. Sales increased from hundreds of thousands of yuan to 700 million yuan today, and tax revenue increased by more than 20 million yuan.

In 2019, Tianyi Machinery ranked the top three in the world and the number one in the country with the single product market share of the composite wall board production line, and became a "national specialty new giant."

After standing firmly in hardware, as an "chain owner" enterprise with ecological leadership with ecological leadership in the prefabricated construction industry, Tianyi Machinery puts attention to the software industry. In 2021, Tianyi Machinery established the nation's first nationwide prefabricated building smart factory Internet platform to combine intelligent sensing technology, 5G technology, big data analysis technology and artificial intelligence technology to meet customer intelligence, flexible, and integrated need.

At present, Tianyi Machinery has obtained more than 300 technical patents, drafted and entered into 18 national and industry standards, and has become the "leader" in the industry, and is at the forefront of the prefabricated building equipment industry.

Go abroad and "tailor -made" to seize the industry market

“建筑墙板最多只能运100多公里,从兖州可以卖到泗水,但是不能卖到临沂,因为运输成本在那里放着,但是装配式建筑装备可以,甚至可以卖到哥伦比亚、沙特阿拉伯、南非Wait. "For the advantages of prefabricated building equipment, Chen Depeng talked," Enterprises sell the equipment production line, not only the transportation cost is low, but also the labor cost is low. Customers can assemble it locally. "

"In industrial buildings, civil buildings, tourism buildings, and government buildings, there are prefabricated building equipment, like the inner ring viaduct in the city, and the modular square cabin hospitals. Construction. "Chen Depeng said that it was the technical support of the upstream prefabricated building equipment industry, and the assembly buildings were quickly unplugged. In some first -tier cities, the building assembly rate has reached more than 50%, and this ratio is also increasing in second- and third -tier cities. With the development of corporate innovation and technology, customers of Tianyi Machinery cover most domestic real estate developers, and there are more than 100 production lines in Hainan alone.

The company adheres to the concept of strong joint and open development. In May 2018, Tianyi Machinery and Germany's largest BIM company ISOCOM established TBT Company. In June 2018, the acquisition of Germany's 36 -year -old assembly building equipment technology enterprise - The BCDS company established its first overseas R & D center in Germany. Comprehensive integration, innovation, and use of German Industry 4.0 technology, the level of intelligent machinery intelligence has taken the international frontier. The first nationwide nationwide prefabricated building smart factory Internet platform combines intelligent sensing technology, 5G technology, big data analysis technology and artificial intelligence technology to meet the needs of customers' intelligence, flexibility, and integration. Intelligent transformation provides an integrated solution. Around the "prefabricated", Tianyi Machinery is not just on the production line.

"We will analyze customers' architectural materials in the early stage. From the aspects of material formula and other factors, it will be matched to the customer's suitable production equipment. At the same time, the technical personnel are sent to inspect the layout and terrain of the factory area on the spot, designing a set of production lines of" local conditions "for customers Plan. "In the technical department of typical Chinese style, Chen Depeng's team is tailor -made for" one -to -one "for customers every day. Integrated solution.

At present, the dominant products of Tianyi Machinery include lightweight wall board intelligent equipment, PC intelligent equipment, steaming pressure and gas concrete (ALC) plate intelligent equipment, insulation decoration integrated board intelligent equipment. Some products have a domestic market share of more than 40%. Products have been exported to 106 countries and regions such as Germany, Saudi Arabia, and South Africa.

Chen Depeng said that constantly innovative products and "tailor -made" services have made enterprises have the right to speak in the industry.

Tianyi Machinery is a technical leading manufacturing enterprise. It always focuses on the research and development, manufacturing, and providing integrated solutions for the comprehensive utilization of solid waste in prefabricated building equipment. Tianyi Machinery has closely seized the rapid development of the rapid development of the prefabricated building industry, adhered to the direction of high -end, high -quality, and efficient development, obtained more than 300 technical patents, drafted and entered into 18 national and industry standards, and has national high -level talents. Four, with more than ten scientific research institutions including the Chinese Architectural Materials Science Research Institute, Hunan University, and Shandong University of Architecture, have established in -depth cooperation in integrated cooperation in industry, university, research. It has won more than 40 national and provincial honors such as "National High -tech Enterprise", "National Manufacturing Single Champions Enterprise", "National Specialty New Little Giant", "National Installed Building Industry Base", "National Green Factory" Essence

- END -

The IPO of the Lilida North Stock

Picture source: Bei Stock Exchange websiteLyda's main business is the research and...

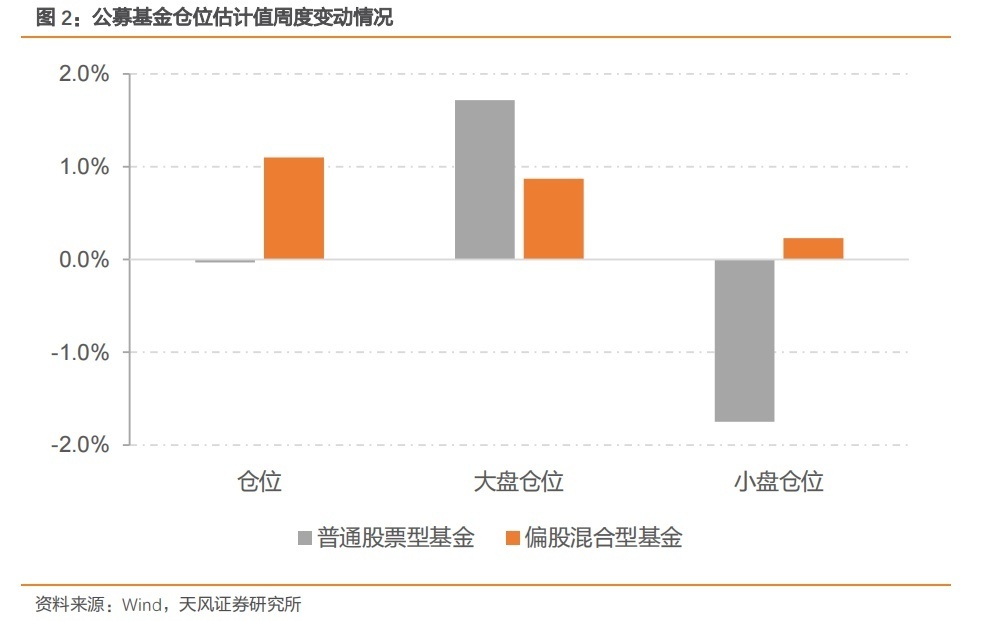

Public -private equity fund positions have rebounded, fund manager confidence index recovers

On July 6, Capital State learned that since April's round of rebound, some public ...