How can I innovate and evolve from imitation to becoming a leading screen in the industry?| The secret of the little giant

Author:Cover news Time:2022.09.01

Cover reporter Xiong Yingying

Entering Chengdu Fist Technology Co., Ltd., which is located in Chengdu Gaoxin West District, there is an ordinary four -story office building in the green tree cover. The decoration and furniture in the building seem to be quite old, which is slightly old and humble. However, it is such an inconspicuous company that developed the first large -scale domestic Fresnel optical screen to fill the domestic gap.

Fresnel's optical screen is a type of optical screen. It is currently widely used in laser TV projection display. Most of the mainstream laser TV brands on the market are Fresnel Optical screens. However, at the beginning of Fist in 1999, no company in China could make more than 100 inches of optical display.

In the past 23 years, what kind of process has this company experienced from imitation to independent innovation to becoming an international leader? What is the secret of being a national key specialty new "little giant" enterprise?

Fest Laser TV screen (Photo Conferring in the Interviewee)

From imitation to independent innovation

Fill in domestic gaps

Wu Qingfu, co -founder of Fist, clearly remembers that on November 18, 1999, he took a backstone optical screen sample to Wuxi to participate in an industry standard conference. With this sample, the company's first 120 -inch Fresnel's back voting optical screen was "pre -sale" at the price of 36,000 yuan. At that time, the domestic optical screen was not yet popular, and the prices of similar imported products were nearly doubled.

The reason why the price is high is mainly because the manufacturing technology is extremely difficult. It is understood that the core component of the optical screen is Fresnel Class, which is a fine structure of optical components, which are widely used in national defense, aviation, industrial production and other fields. The design and manufacturing of large Fresnel lenses involves multiple technical fields such as optical engineering, polymer materials, ultra -precision molding technology and equipment manufacturing.

In fact, Fist at that time did not really master this core manufacturing process. It only adopted the most basic way. One by one, the products that went to "cloned" foreign countries have not been high.

The turning point appeared in 2002. This year, the company obtained the number of national projects on the TV screen digital, and the demand for expanding production capacity became urgent. This also made the team realize that imitation is not a long -term score and must break through the large -sized Fresnel lens manufacturing technology. In order to achieve the large -scale production of the product.

Therefore, under the difficult situation of no learning sample, no ready -made technology, and no equipment introduction, the startup team of more than 20 people began a night -day research, while conducting a decomposition of advanced foreign products, while conducting ultra -precision mold processing equipment while carried out an ultra -precision mold processing equipment Research and development independently. It took more than six years before and after, and finally overcome this technical problem, becoming the first domestic manufacturer to make large -sized Fresnel's optical screens in batches.

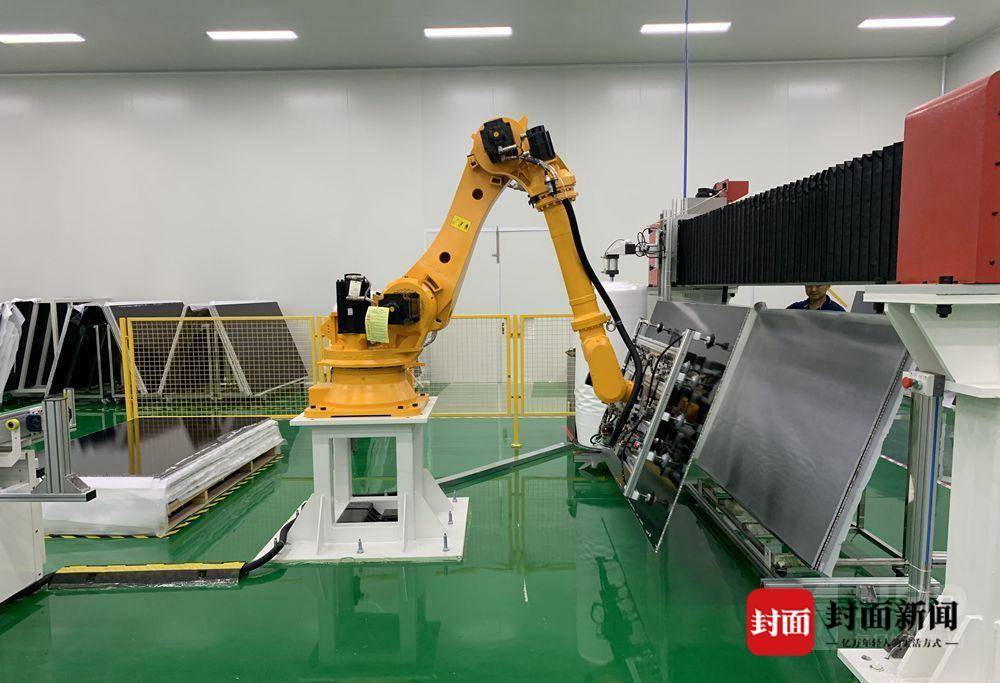

Fist Factory (Photo Conferring in Interviewee)

Break the industry giant monopoly

Do the native first

In 2013, with the advancement of projection display technology, laser TV came into being. Based on the technical accumulation of optical fields, Fist began research and development of laser TV optical screens. Two years later, the company appeared at the international multimedia audiovisual integrated exhibition held in Beijing with the latest 100 -inch ultra -short -focus laser TV Fresnel.

"The exhibition lasted three days, and the Japanese DNP people looked at us six times in the booth." Wu Qingfu mentioned that as a global optical screen manufacturing giant, DNP is the first company to develop 100 -inch Fresnel optical screens. "So They once suspected that we bought their products to participate. "

DNP shows great interest in this sudden competing rival. After several consecutive days of exchanges, the two parties held a cooperation conference. DNP proposed the idea of cooperating with Fist to establish a joint venture company, but Fei Ster did not agree. "I know very well that our screen is better than them, the screen brightness factor is higher, and the lens is thinner. Now we can do 120 inches, they can't do it." Wu Qingfu's words were full of confidence.

Although the cooperation failed, the DNP executives flew to Chengdu with technical staff and translators on the second week after the exhibition. "They wanted to visit the company's production line and were rejected by us. During dinner, they proposed to be able to exchange a screen." Wu Qingfu recalled that the company's founder Zhang Yimin agreed on the spot and said that he could send the other party for free. Although this screen was not really delivered in the end, it has shown the strength of this unknown company. Actively embrace the capital market

Let the laser display enter the family

From the earliest backstop optical screen, to the current laser TV optical screen and intelligent projection optical screen, after more than 20 years of technological innovation and product change, Fist has also settled in the leading position of the industry.

At present, the company's laser TV display accounts for more than 30%of the national market, becoming an important supplier of well -known companies such as Hisense, Changhong, Xiaomi, and XGIMI, with an annual output of optical screens of 500,000 pieces. At the same time, the brightness coefficient of the laser TV screen of its production reaches 1.6, and on this basis, the three -base color of the laser screen can be made to achieve higher resolution and display accuracy.

In December last year, Fist completed a round C financing of over 100 million yuan. It was led by the Qing Da Strait Investment. CITIC Investment Capital and Chengdu Rongxing Venture Capital and other institutions followed up. etc. "The plan will expand the production capacity to 2 million pieces in the future. At the same time, the company has also entered the listing counseling period. I hope that in the future, it can be listed on the science and technology board." Wu Qingfu said.

According to relevant industry reports, in the first half of 2021, the downstream application market of laser display in my country ushered in a high -speed growth. According to Luotu data, in addition to the decline in the sales of education scenarios, the sales of other application scenarios have increased significantly. Among them, the sales volume of household scenarios increased by 42%, business scenarios increased by 400%, engineering scenes increased by 531%, and theater scenes increased by 120%.

How to grasp the future development trend of the industry? Wu Qingfu believes that "First, the screen gain needs to be improved; secondly, if it is only used by ordinary families, there is no need to pursue too much viewing perspective." In his opinion, compared to LCD TVs, laser TV has strong eye protection ability and broad market space. However, in order to truly achieve popularization, technical adjustments and breakthroughs should be made in combination with the demand of the home market.

- END -

"Zhu Rong" will welcome the Martian winter solstice

The Zhu Rong Mars northern hemisphere in Mars will usher in the winter solstice on...

One article takes you to understand the Toppon S465-24 storage server product stability is stronger

In recent years, the market demand for data storage has continued to rise, which h...