Hubei!Hubei!Good "screen" like a tide!

Author:Changjiang Daily Time:2022.09.04

Together by the Central Radio and Television Terminal and the Ministry of Industry and Information Technology, a large -scale financial media reported by the Finance and Economics Center reported "Intelligent Manufacturing China", which has recently focused on Hubei.

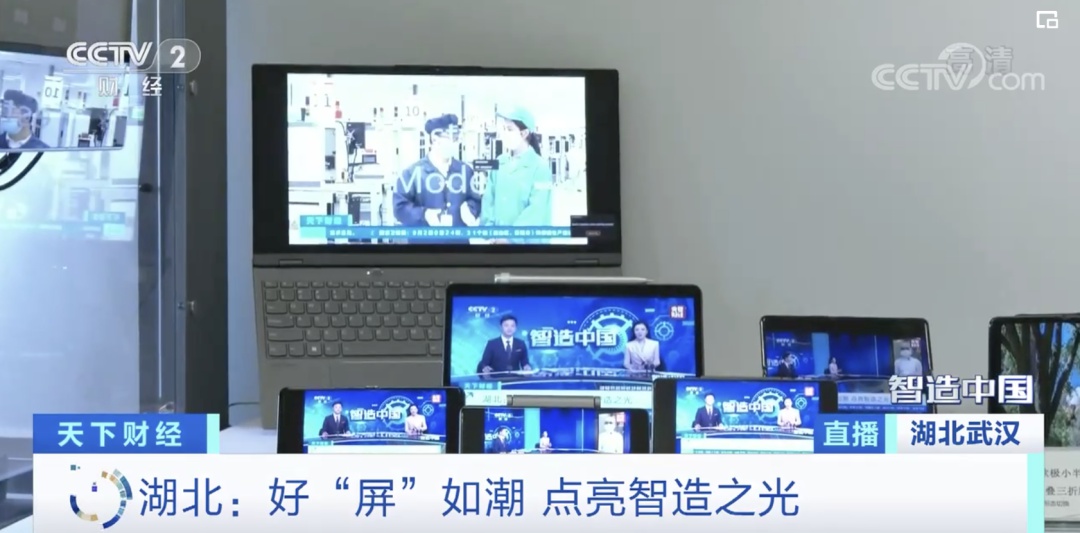

The optoelectronic information industry is the most beautiful business card in Hubei Province, which is known as "China Optics Valley". Hubei has the largest and most comprehensive small and medium -sized display panel production base in China. From the "lack of core" to the good "screen", how can the domestic screen accelerate the rise through intelligent manufacturing?

Hubei: Good "screen" is like the tide to light up the light of smart manufacturing

△ CCTV Finance "World Finance" column video

The reporter came to the production workshop of TCL Huaxing Optoelectronics, and many TVs, computers, and mobile phones were produced here.

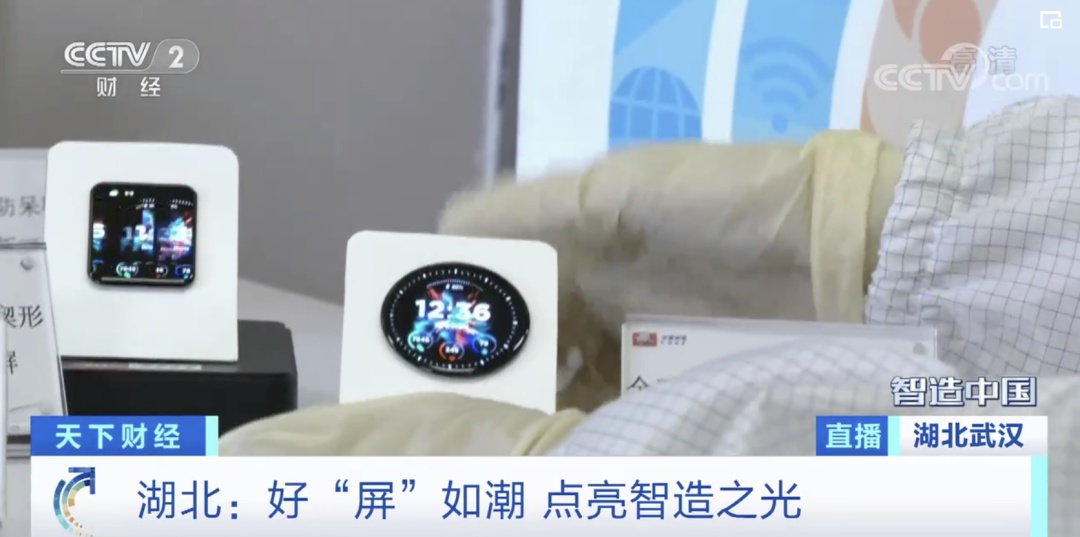

Some of the "screens are the most" here, such as the world's lowest refresh rate wearable device screen. The low refresh rate means low power consumption and can be long standby.

A folding mobile phone, using the narrowest folding screen of the frame, only 1.8mm, almost no creases, not only with two folds up and down, but also a screen with a 30 % discount inside and outside.

In a machine here, 9 folding screens are placed. The simulated human hand is folding. It can be folded 30 times in one minute. A screen requires 200,000 crazy folds to test performance.

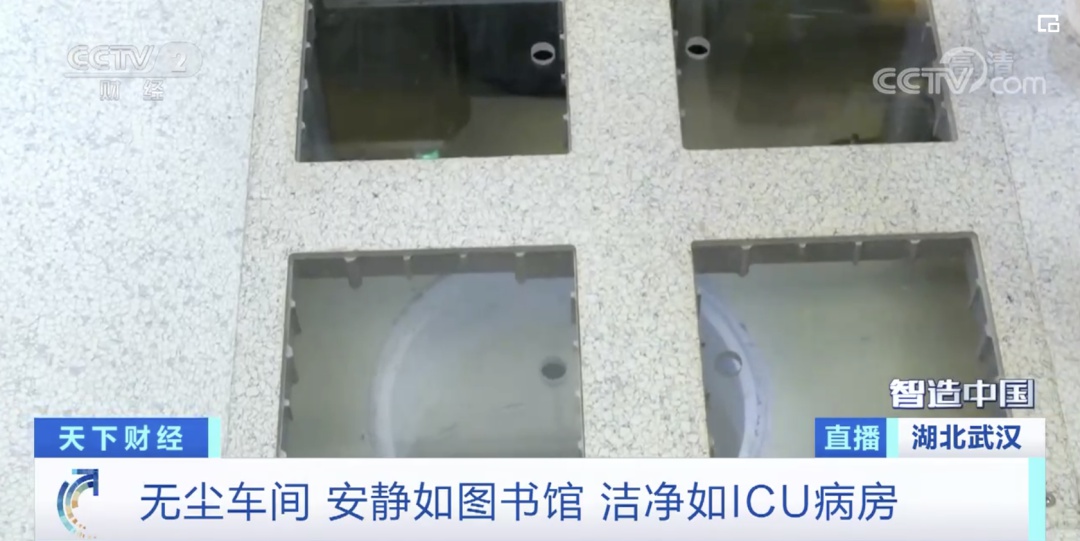

The dust -free workshop is quiet as the library is as clean as the ICU ward

There are also domestic leading flexible panel production lines. Compared with the traditional production workshop with sparkling splash and roaring mechanical roar, there are only very few workers in the production workshop, like a quiet library, and very clean. The reporter was wearing a strict conjoined dust uniform, and he had to wash his hands twice, step on the dust mats, and take a blowout of the wind chamber before entering the workshop.

The floor here is covered with small holes. Below the floor is a large -shaped pore of 35cm diameter. The role is to allow the dust in the air to flow to the ground through the hole, and the fine pores of the ceiling are sent to the purification that has been purified. Clean the air, the cleaner the factory building, the higher the quality of the screen produced. The entire factory cannot see a pipeline. The entire production is completed by more than 1,000 automated equipment and more than 600 robotic arms. Here is a wonderful journey with glass transformation into the screen every day.

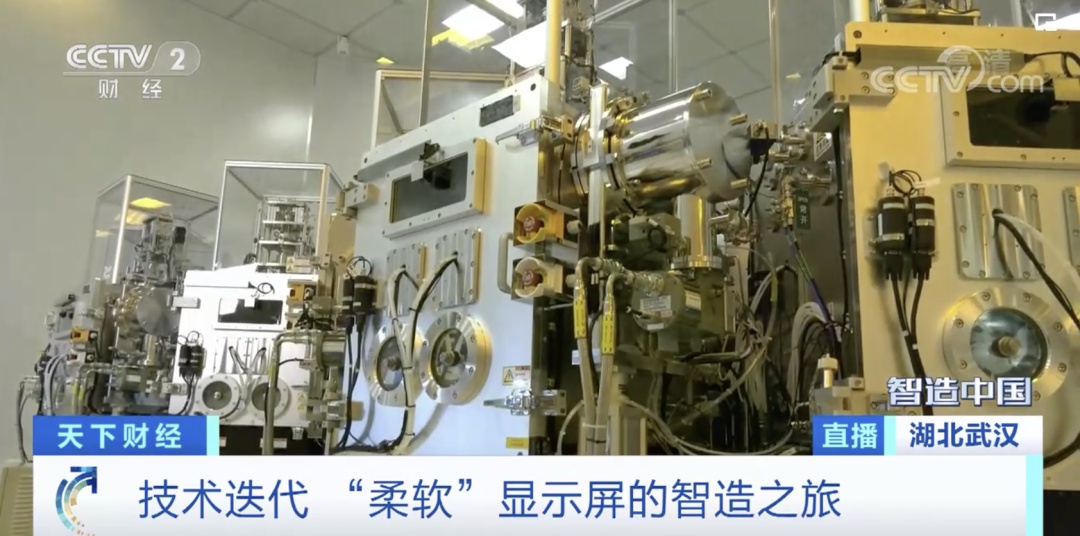

Technical iterative "soft" display intellectual building journey

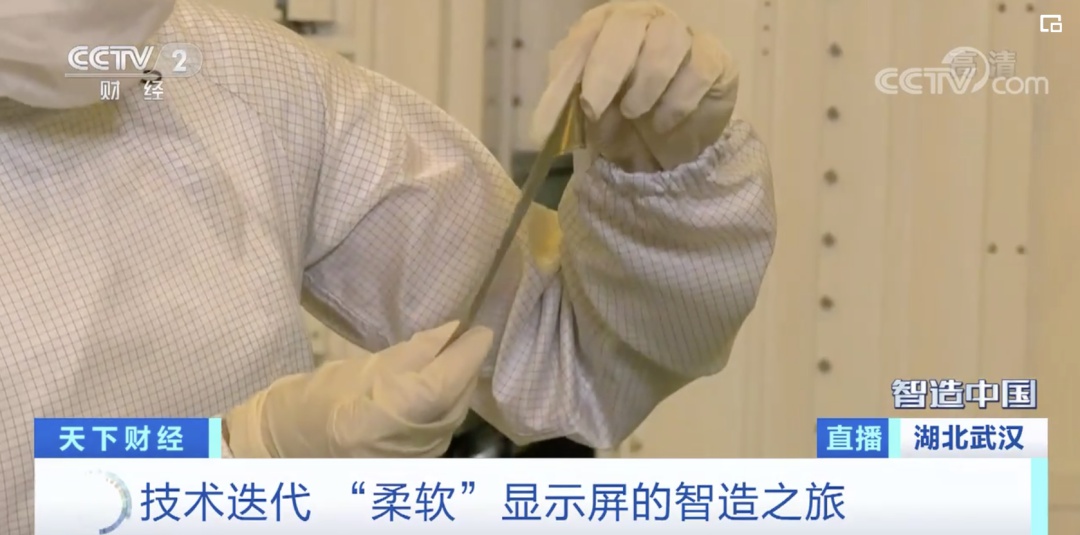

How is a flexible screen made? First of all, the glass is transported into the device by the robotic arm and coated with a layer of flexible base materials. It is one of the core materials that realize the flexible screen. Most of these materials are monopolized by foreign countries. After that, the circuit layer needs to be used, similar to the EXCEL vertical grid. Each grid is a pixel and an independent switch. The circuit layer is the switch of each pixel point.

The reporter saw the original line of the line through a microscope, only 3 to 5 microns. These lines formed tens of millions of small switches. Under the size of a nail cover, there can be 336,000 such small switches.

After the switch is done, enter the most critical link -connecting the light bulbs to these "switches" and making "small bulbs" equipment is called steamer, the price is hundreds of millions of yuan. The steaming process is similar to steamed buns. It is used to cover the template, which is similar to the sieve under the glass substrate. Each sieve is performed on each concave pit. inside.

After the steaming is finished, it can be encapsulated by a machine to prevent the invasion of water vapor and oxygen. The lights in this area are yellow, because the materials used for packaging are more sensitive to light. The products after packaging are slightly yellow, and then they are irradiated with laser to peel off the flexible base from the glass.

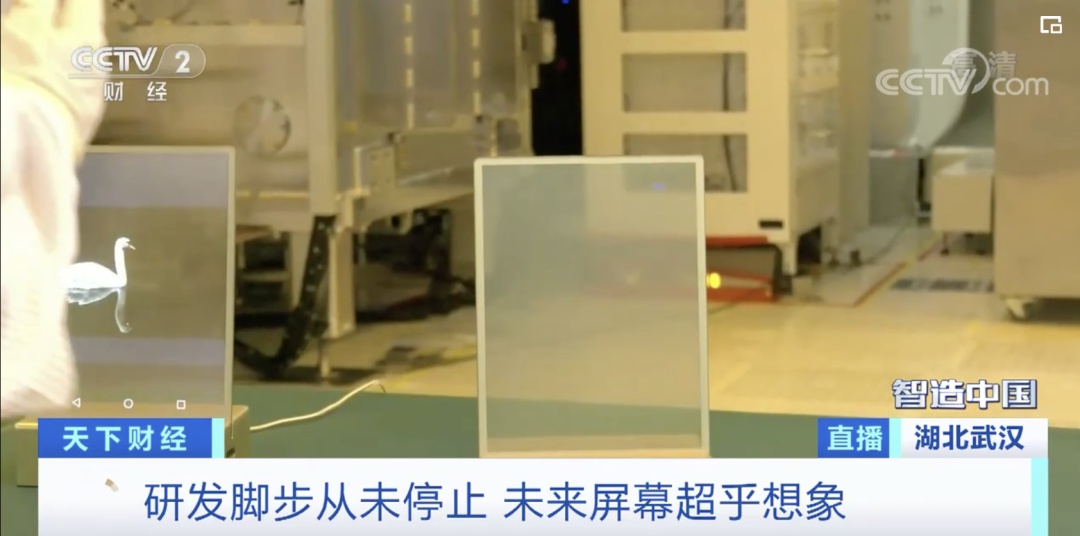

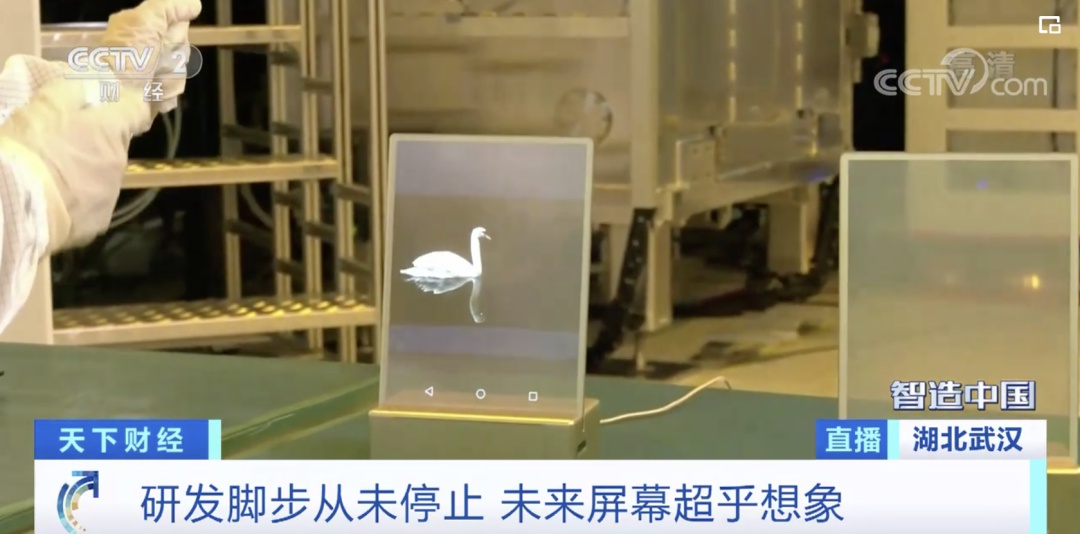

The pace of research and development has never stopped the future screen is beyond imagination

There are also screens like transparent glass, which exceeds 55%, but after lighting, you can display high -definition and bright pictures. This is the latest transparent display technology. If such a screen is used as a window, it does not display it. At the time, you can watch the scenery outside the window. After lighting, the window becomes a display screen, becoming a scenery in the eyes of others.

my country's panel production has not only led the world in terms of scale, but also some technologies have also led the world, and the pace of research and development innovation has never stopped. Maybe in the future, more screens will break our imagination and bring a new viewing experience. Hubei: Ten years of grinding a "line" mobile phone "smart manufacturing" to accelerate running

△ CCTV Finance "World Finance" column video

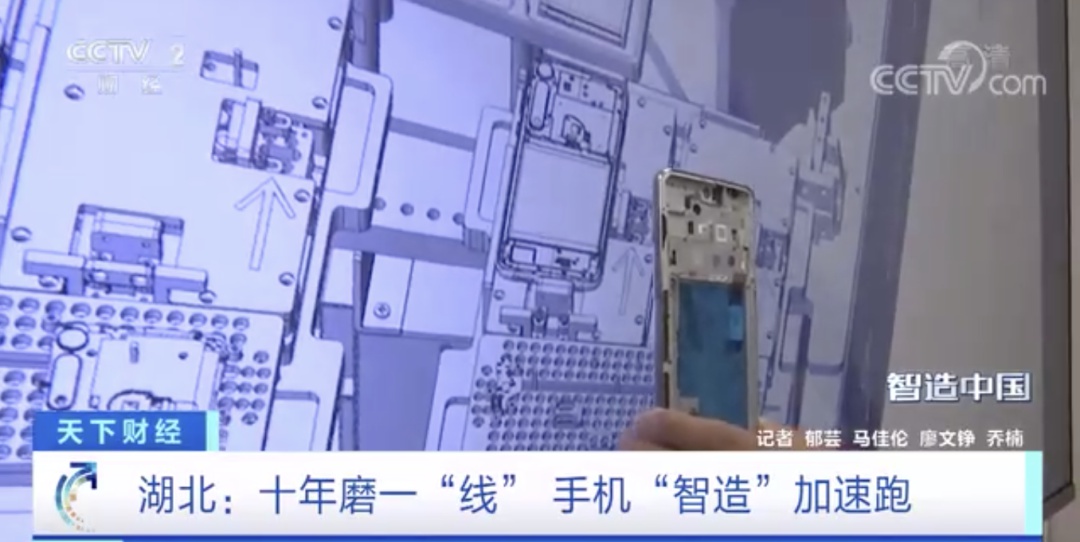

The production line is a lifeline manufactured by the industry. The continuously upgraded intelligent production line gives industrial manufacturing stronger potential energy. In a mobile phone manufacturer with the largest export volume in Hubei, the automated engineer grinds a "line" for ten years to help the production line running out of the acceleration.

To assemble a large -scale mobile phone, do dozens of processes such as patch, testing, assembly, and packaging. There are thousands of parts, the smallest less than 0.2mm. Therefore, especially in the assembly link of mobile phone, a large number of artificial labor is still needed, which is the pain point of the industry.

Hu Xuzhou, the production line automation engineer, his task is to take into account the cost and efficiency, and to achieve "device replacement" as much as possible. In order to increase the degree of automation of the production line, Hu Xuzhou led the team to hold countless feasibility assessment meetings. Each discussion was almost "quarreled." The recent "quarrel" is mainly whether the robotic arm can automatically install the battery.

The production cycle of the new "100 million offline" products is shortened by half

If you ca n’t solve the drawings, then compare it on the ground next to the production line. In order to restore the flexible movements of people's hands, Hu Xuzhou needs to shoot videos of artificially assembled batteries at multiple angles, and then go back to play and simulate the design. This method is the most effective, and it has also witnessed the increase in automation rates year by year. In 2019, the Lenovo Wuhan Industrial Base was launched in the line of 10 million units, which took a total of 6 years. Just early next year, the second 100 million units will be ushered in here, but this time it takes only 3 years.

Today, the automation rate of this mobile assembly line has increased from 14.8%ten years ago to 48%today. On each production line, the output of 49 workers with a shaft was completed. Now with automated equipment, 28 people can easily complete.

Now on this production line, robots and workers sit in staggered and perform their duties. At a distance of the production line, there is a transparent glass cover. The white small robotic arms inside shake their heads and grab the parts up and down. They are responsible for getting multiple processes such as mobile phone assembly, testing, and inspection output. Ten years of grinding a "line", Hu Xuzhou led the team to lead the industry.

Hubei: Light the world in the name "Light"

Hubei is a large industrial province in central my country. The optoelectronic information industry is unique in the country. How can traditional manufacturing provinces rejuvenate and vitality, from intelligent manufacturing to Hubei creation?

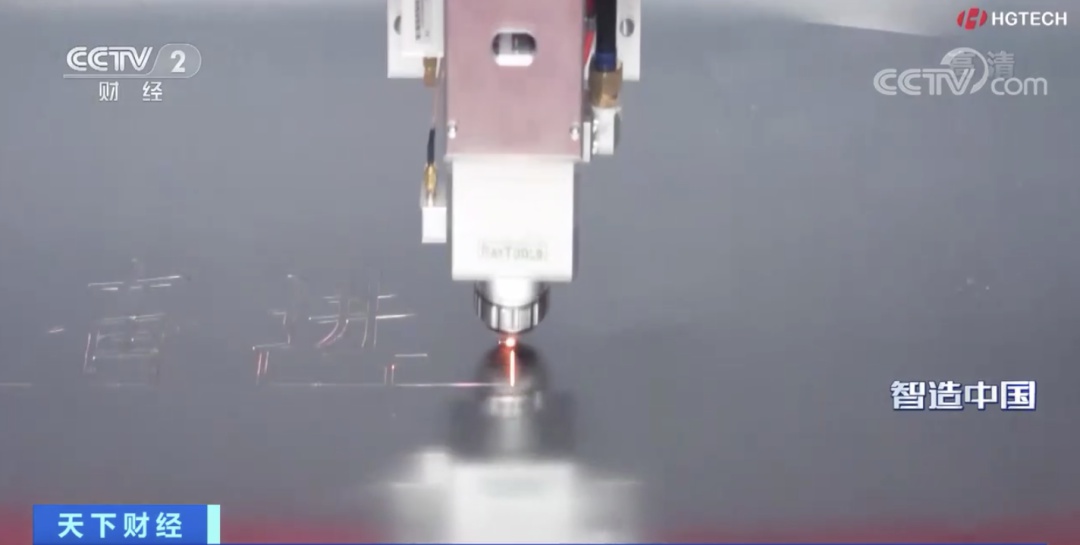

Laser is also known as "the brightest light, the fastest knife, and the most accurate ruler." Intelligent equipment is widely used in semiconductor, metal processing and other fields. At the workshop site, the reporter saw that whether it is several millimeters or hundreds of millimeters of metal plates, they can be "iron -cut like mud". Essence

From the accuracy of parts and components, the level of process, and the degree of standardization, mass production can be achieved through intelligent control. The product category of laser manufacturing in Hubei accounts for 70%of the country, and the output value of laser equipment accounts for 50%.

The laser industry is just a microcosm of the Hubei Optical Electronics Information Industry Cluster. As a golden signboard in Hubei Province, it has become the largest domestic optical component production base and optical communication technology research and development base. It is known as "China Optical Valley".

Rely on "Old" Huan "New" to go together

In order to promote the accelerated transformation of the traditional manufacturing industry, Hubei Province has introduced measures such as "technical reform and capacity manufacturing". Automobile is the first pillar industry in Hubei Province. Hubei Province focuses on new energy vehicles and intelligent connected cars, and promotes the in -depth application of new technologies in key links such as automotive research and development, manufacturing, and other key links.

Hubei production capacity reached 2.1 million vehicles last year. There were 25 manufacturers manufactured by vehicle manufacturing. 75%of the component manufacturing was produced through the smart manufacturing line.

It is necessary to comprehensively improve the level of intelligent manufacturing. There are more than 17,000 small and medium -sized enterprises in Hubei, accounting for nearly 90 % of the market players. Driven by leading enterprises, intelligent upgrades are undergoing intelligence.

Hubei has set up high bandwidth information transmission networks for SMEs, provides hardware support, organizes some professional institutions, and diagnose these small and medium -sized enterprises to provide a solution to improved transformation to SMEs.

Science and education building the base of intelligent buildings move towards creation

Driven by a series of measures, Hubei Province has cultivated more than 20 national R & D platforms in the field of intelligent manufacturing, and selected 196 smart manufacturing demonstration companies. In 2021, the digital economy scale increased to 2.1 trillion yuan, ranking first in the central part. By 2025, the value -added of the manufacturing industry in Hubei Province will reach more than 30%of the province's GDP.

Hubei science and education is an important advantage. There are more than 150 universities and a group of vocational colleges that can be closely integrated with industries in the manufacturing field to customize talents. Facing the future, the goal is to create efforts to China.

(Source: CCTV Finance)

【Edit: Shang Pei】

For more exciting content, please download the "Da Wuhan" client in the major application markets.

- END -

Jining High -tech Zone: To help enterprises climb as a strategic traction from dots and faces to promote the high -quality development of the manufacturing industry

Since the beginning of this year, Jining High -tech Zone has resolutely implemente...

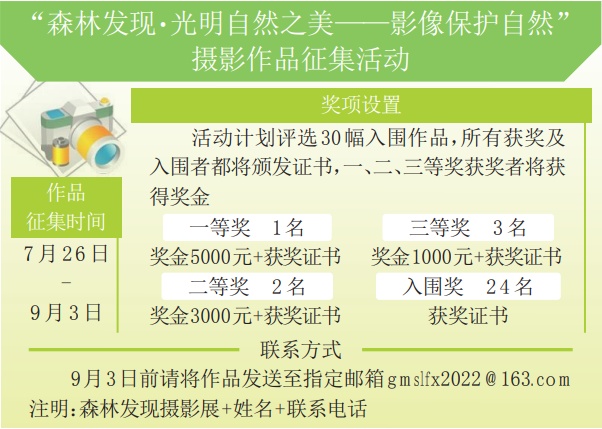

"Forest Discovery · Light and Natural Beauty" photography collection activity is waiting for you

In order to show the Blue and Green ecological base of the Guangming District Inte...