Science and Technology Summit 丨 Tan Jianrong, Academician of the Chinese Academy of Engineering: Scientific design is the key to the manufacturing power

Author:21st Century Economic report Time:2022.09.23

21st Century Business Herald reporter Yang Qingqing Beijing report

From a manufacturing country to a manufacturing power, it is inseparable from the transformation and upgrading of manufacturing companies. What are the key links in the transformation and upgrading process of manufacturing companies?

On September 23, the "2122 212 Century Science and Technology Summit" hosted by the "2122 Economic Herald", hosted by the "2122 Economic Herald", was officially held. In the keynote speech of the "Strategic Trend" of the summit, Tan Jianrong, an academician of the Chinese Academy of Engineering, gave his answer.

"Scientific design is the key to moving from a large manufacturing country to a manufacturer. We must innovate independently and design first. To become a manufacturing power, we must first scientifically manufacture, and scientific manufacturing must first be scientific design. The design and visualization of design are scientific design. "Guarantee." Tan Jianrong believes that in this process, the application of digital twin technology is worth looking forward to.

Manufacturing transformation emphasizes scientific design

Tan Jianrong pointed out that the new generation of information technology has four remarkable features, including from the Internet to the Internet of Things, from virtual reality to augmented reality to recent Yuan universe, from network computing to cloud computing, from machine learning to deep learning, in these technologies, in these technologies, in these technologies, in these technologies In the process of evolution, there were also cross -fields including industrial interconnection, hybrid reality, big data, and artificial intelligence.

At the same time, my country's manufacturing enterprises are still at the middle and lower end of the industrial chain and need to be transformed and upgraded. "The transformation and upgrading of Chinese manufacturing enterprises requires basically relying on advanced technologies to achieve, that is, relying on digital manufacturing, networked manufacturing and intelligent manufacturing." Tan Jianrong said.

It should be noted that Tan Jianrong believes that in the process of using digital, networked, and intelligent technologies for transformation and upgrading, digital manufacturing is the core system. "We need to do intelligent manufacturing. First of all, we need to make digital manufacturing and use digital manufacturing to achieve digital transformation."

Tan Jianrong pointed out that digital manufacturing mainly involves digital design, intelligent processing, intelligent assembly, digital assembly, and digital and intelligent services. These need to use digital twin technology behind these. Digital design superimposed digital twins can help companies achieve interactive feedback and data fusion in the product design process, thereby achieving optimization of decision -making iteration.

"Design is the key to moving from a large manufacturing country to a manufacturing power. We must innovate independently and design first. To become a manufacturing power, we must first scientifically manufacture, and scientific manufacturing first requires scientific design. The design and visualization of design are scientific design. Guarantee. "Tan Jianrong emphasized.

There are three major methods in the current engineering science, including theoretical modeling, experimental verification, and simulation simulation. In Tan Jianrong's view, combining virtual reality with actual technology is an epoch -making revolution. The product function verification and performance analysis are performed by replacing the experimental prototype through digital prototypes. It can reduce product development costs and shorten the product development cycle. The main means of independent design and independent innovation.

Three major trends in digital twins

When interpreting digital prototypes and digital twins, Tan Jianrong listed many cases.

Tan Jianrong pointed out that digital prototype technology can be traced back to the concept of virtual reality in 1965, and the US Department of Defense proposed scientific computing visualization in 1987. In 1994, Boeing took the lead in realizing the product design of digital prototypes on large aircraft. In 2000, IBM proposed digital management of the entire life cycle of the product. Ford also applied digital prototype technology to enhance the core competitiveness of the product, and applied digital design and digital twin technology to all aspects of automotive design and equipment manufacturing.

The concept of digital twin was born in 2003, involving the connection between physical models, virtual products and the two. "Digital twins include testing and verification of knowledge product performance and functions such as product information modeling, assembly modeling, simulation simulation, etc., and optimize iterations through historical data, manufacturing data, and maintenance data of the product to improve product design." Tan Jianrong Rong Rong According to the introduction, "Digital twin emphasizes the integration of false and reality and sequencing control. By displaying, statistics, analysis, and processing multi -channel information and multi -channel interaction to achieve real -time monitoring and control of physical products and the surrounding environment."

At present, the application of digital twin technology has a relatively successful precedent for product design. For example, Tan Jianrong said that during the design of Dasau's phantom series of fighters, Dasau developed a 3DEXPERIENCE platform based on digital twins, including social collaboration, three -dimensional modeling, virtual simulation, intelligent information processing and real -time experience.

According to reports, the 3DEXPERIENCE platform continues to improve the product design model in the information world by using information feedback from user interaction, and feeds back to the improvement of physical entities. The platform was applied in the design and manufacturing of the Phantom series of fighters, reducing the waste of 25%and increased quality improvement by more than 15%for the first time.

In addition, Tan Jianrong mentioned that Siemens established a production system model for integrating manufacturing processes based on the digital twin concept, forming a model -based virtual enterprise and automated enterprise mirror image. The degree of production process automation, personalization, elasticity, self -optimization and improvement of production resources, reducing production costs for production resources, and reducing production costs, which greatly improve production efficiency, save production resources, and reduce production costs.

Tan Jianrong pointed out that there are eight key technologies in digital twin and digital design, including complex equipment polyphonic heterogeneous data conversion and integrated technologies, complex equipment geometry-physical-behavior-behavioral modeling technology, complex equipment digital twin multi-performance coupling analysis technology,, and Digital twin behavior simulation technology, complex equipment all life cycle operation process simulation technology, smart workshop layout planning and production scheduling optimization technology, operating status visual analysis and fault intelligent prediction technology, and maintenance operation navigation technology. Facing the future, Tan Jianrong believes that twins exist in three major development trends. The first is to be integrated, involving multi -physical modeling. "The degree of success of product digital twins in the industrial field depends on the degree of integratedness of product digital twins. Study how to associate models based on different physical attributes, to establish product digital twins, and then give full play to product numbers. The key to the role of twin simulation, diagnosis, prediction and control. "

The second trend is the periodic of the whole life, which is extended from the product design and service phase to the product manufacturing stage. Tan Jianrong pointed out that at this stage, the research on product digital twins mainly focuses on product design or after -sales service stages, and less involves the product manufacturing stage. Digital twin will become a new hot spot in the research and application of product manufacturing stage.

In addition, integrated and integrated technology integration will also become a new trend. Tan Jianrong believes that there are still breakpoints between various links of digital twins at this stage. How to use digital bond technology as the basic technology, combined with new generation of information and communication technology, big data analysis technology, enhanced reality (AR) technology and other advanced technologies Organic integration is the next research direction of digital twins.

- END -

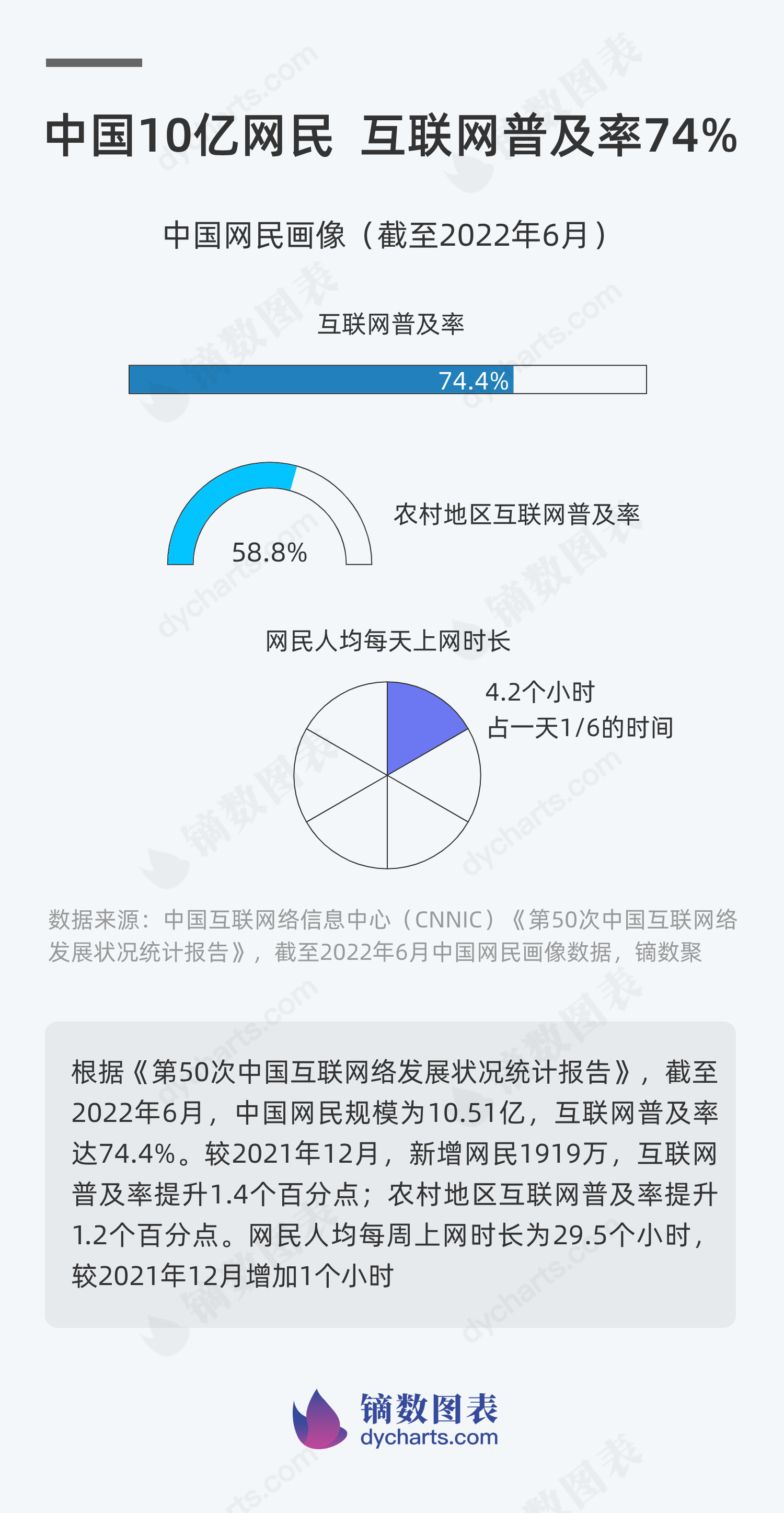

The number of Chinese netizens is as high as 1 billion, and the Internet penetration rate is 74%

According to the 50th China Internet Development Statistics Statistics Report, as ...

A "love letter" written to Chengdu by a photographer: Looking at the snowy mountains for three and a half years to become a delayed photography affectionate confession [Qi Xin war into Chengdu, Chengdu can do]

Cover reporter Song Xiao Yang TaoWhat are you doing in three and a half years? Fo...