Weekend Story ㉟ | Cononis B series engines are localized

Author:Dongfeng Motor Time:2022.09.17

Oral person | Hu Fu (formerly Dongfeng Motor Technology Center engine expert, researcher -level senior engineer)

In 1963, I graduated from the Department of Dynamics of Tsinghua University's Dynamic Automobile, Track and engine major. In September 1967, the factory came to the factory to support Erqi. With the dream of "from scratch with a engine", I signed up to participate in the construction of Erqi. At that time, I broke my milk for more than 5 months, all held to a worker's house in FAW, and ran to Shiyan myself.

When I came to Erqi, I was divided into the product group of the shaft tile factory. The design of the piston, the piston ring, and the bearing design. At that time, there were only three designers in the group. The laboratory was also built.

Hu Fu

In 1980, Erqi Malaysia 6110 diesel engine was transferred to the technology center as the team leader and was responsible for the coordination of the project. From 1980 to 1988, we did four rounds of trial production. Every round of ideas is different. Seeing a information today, I hope to be realized tomorrow, which is equivalent to every round. In this way, one round of overthrowing a round is twisty and difficult as "changing the dynasty". During this time, you can't sleep at night.

In 1985, I went to the United Kingdom and Germany to obtain a lot of first -hand information with the delegation. According to the results of the Cato consultation, in the fourth round of changes, the diesel engine cylinder, cylinder head and other parts were modified until it was fixed.

In this process, everyone does not know how much effort is spent, how many hardships, how many ways to go, but never defeating ... This may be the process that must be experienced by independent research and development. This result finally won the second prize of China Automobile in 1988.

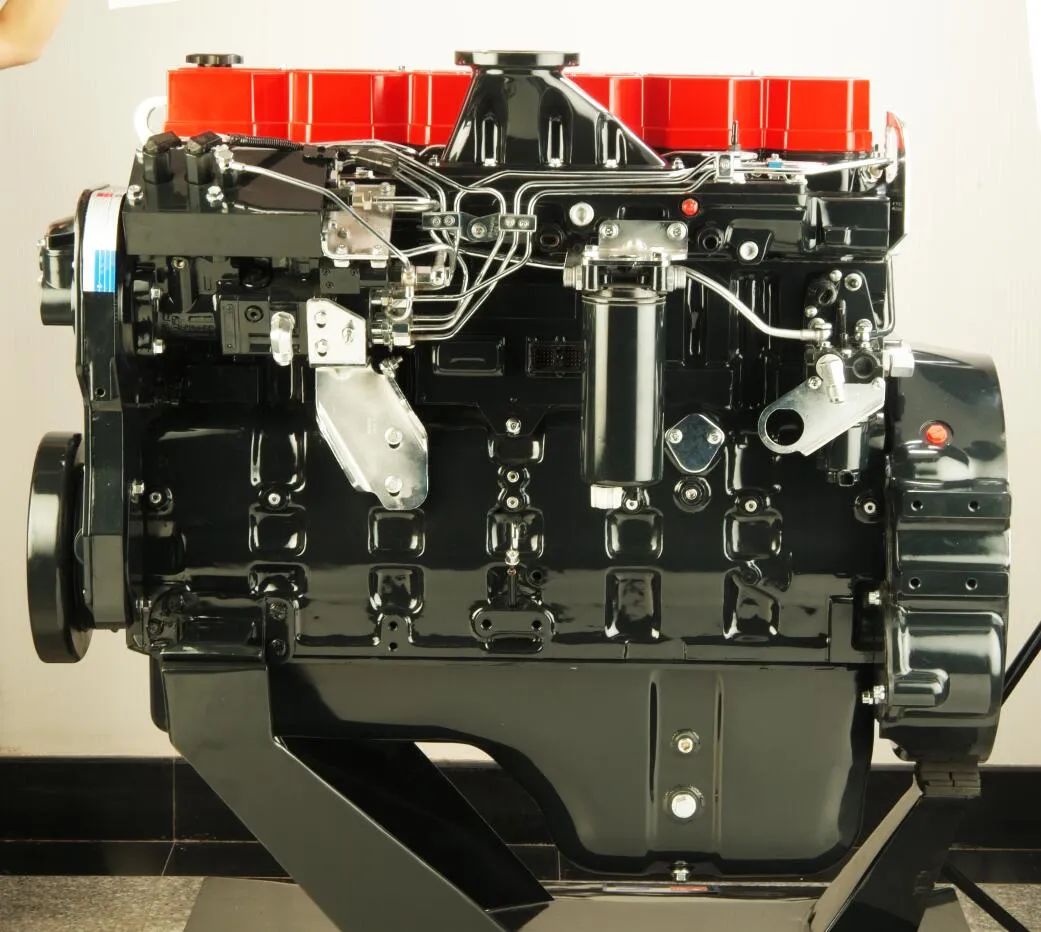

Just when the 610 engine design mission was about to be completed, I was transferred to the design introduction group of Conomin to engage in the localization of the Conominus engine to review, review, and distribute relevant technical documents and product development drawings. A total of 45 sources such as cylinders, cylinder heads, crankshafts, air compressors, and refrigerators in the 6BT engine to conduct professional judgments to see if they meet the requirements of domestic installed capacity, and strive to reach 50%of the domestic production rate.

In 1988, the process was required to install a cover on the oil pump shell, and it was fixed with spring swelling. This small parts manufacturing process was quite complicated, and it was difficult to complete several times. I usually pay attention to the update information of Conomin. After I learned about this, I found that after consulting the relevant information, I found that the new structure has been replaced with a small screw fixation. Crafts, solve the problem.

Here, we found that the tolerance on the Cumminus drawing is completely different from the tolerance on our drawings. In order to not have any problems in use, we generally make the drawings strictly, but the tolerance of the Kangmingus drawing is very loose. I asked them: "Why can the tolerance be so loose?" The people of Cummins told us, "It is not to be stepped up by the tolerance of the drawings, but by controlling the quality control of the process." Because there is a normal distribution, when the engineering ability index is equal to how much is equal to how much is the engineering ability index equal to What are the things that are thrown away on both ends. In this way, the drawing can be relaxed appropriately, and the entire process can be relatively less input.

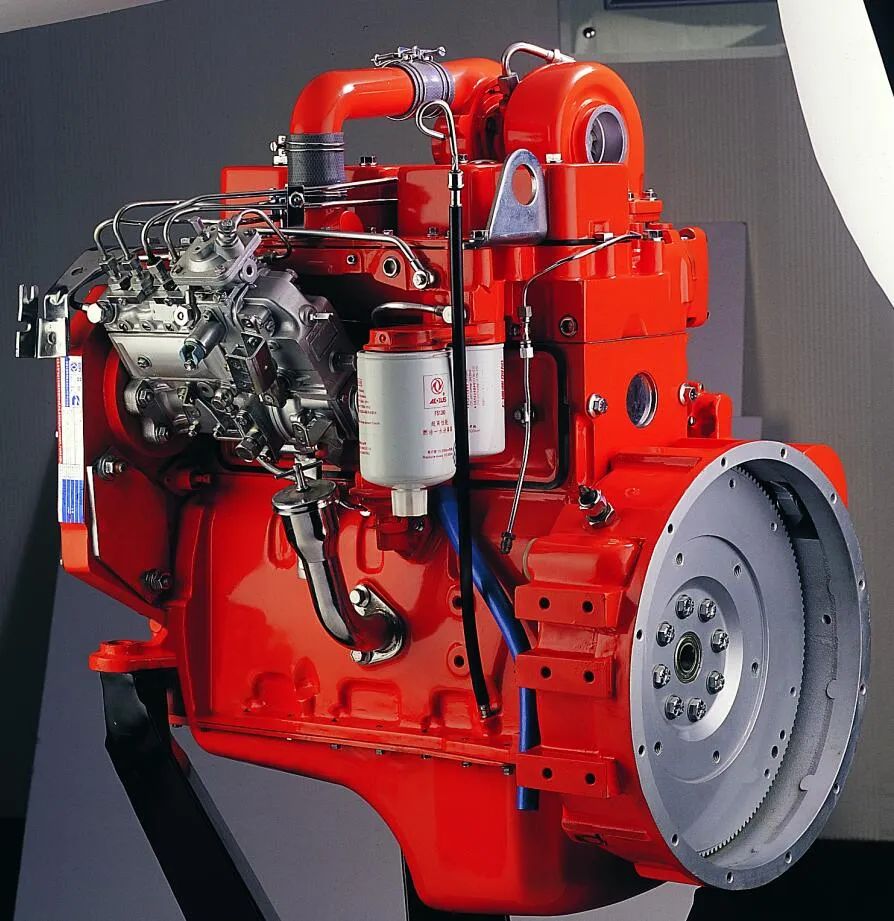

Conomin B140-20 engine

In 1989, I transferred to the Cummins project as the team leader and sent it to Xiangfan for four months to assist the factory to make production. In 1990, when I was nearly 50 years old, I went to Conomin to participate in a half -year training. We always went to the factory to find technical difficulties: to see how they measured them on the quality measurement room; Just look at the craft card and ask the technician consultation with questions ...

While serving as the leader of the Conominus project, the B -series engine sources were appraised and implemented in strict accordance with the Cummins standard, which was extremely difficult. Before Dongfeng Company had not experienced it. I undertake this work, so that the supply and testing of the Cononal 6BT engine parts is progressing smoothly, laying a good foundation for the domestic rate target proposed in 1992. In the related technical work of the B series engine, I put forward many beneficial suggestions for the development of new products, such as 4 -cylinder engines. In 1992, 30 photos of the 4 -cylinder machine diagram review column were successfully guaranteed to ensure the development of new products. In the current production cooperation and external communication work of the B series engine, I went to Chai Fa to deal with the existing production problems four times. I also assumed a large number of technical issues discussions and translations, and consulting the sub -factory of parts production, such as the system, such as the system, such as the system, such as the system. Pump factory air compressor water pump consultation, oil pump consultation consultation.

Dongfeng Conominus Factory in 2003

In 1992, a total of 18 technical issues were issued, including inspection standards and parts assembly conditions for the entire B -series engine and some parts, and reported the judgment of the localization project to judge parts and organizational engine assembly. ensure. This year, I won the title of "March 8 Red Banner" of Dongfeng Company. In 1993, I was honored by Dongfeng Company with outstanding contributions. In 1994, I was rated as a ministry -level expert by the Ministry of Machinery.

From the design engine to the localization of the imported engine, in this way, I will never be able to lose in the study and practice. Especially in the process, I crossed English Pass (Middle School and University studied Russian). In 1985, during the 6110 engine closing stage, in order to master English as soon as possible, I was 46 -year -old and went to the English correspondence class. After attacking the English level, when I dealt with foreign friends, I had more confidence, a mature, and a force when dealing with foreign friends. Conomin 6B engine

Recalling the journey, although hard, it is a good exercise for me. FAW and Dongfeng are very able to cultivate people. Leaders are always purposeful and consciously let me go to some fields. The theories I have learned have been well practiced in practice. The young people of that era accumulated rich experience in the workshop and in the test site, and accumulated rich experience. Now young technicians must go, think about how to learn well, and find the best way to grow up.

Text | Xiong Qiulin

Share interaction

Looking at the story of the localization of Conominus's engine, what do the friends feel? Do you think of more stories about the construction of Ebahi? Welcome to share a message below ~

Push · Reading · Reading

☆ Build a first -class diesel engine factory

☆ Draw the first set of whole set of vehicle teaching hanging charts

☆ Erqi out of the mountain and build Xiangyang base

☆ Yagu capital! Drive to Tibet's Dongfeng "plateau car"

☆ Major pioneer: Erqi and the automotive industry "Great Union"

☆ The only full -time undergraduate university named after the car named after the car

☆ How can Erqi "die and live"?

☆ The gorgeous turn from transportation to car building

☆ Rao Bin points will enter Hao Wentao into the mountain

☆ Hand -painted ebamou's first set of car school pairs

☆ My childhood was in Erqi

☆ How did the first load of Erqi come from?

☆ In addition to designing "Double Feiyan", I also designed these Dongfeng cars

☆ Only "Dang Dang Dang Dang"? And "ah ah ah ah ah"!

☆ I worked with the "Hero Car" through the gunfire rain together

☆ Half -ton gold is replaced back to the "National Treasure Line"

☆ Here is the laughter and tears of several generations of Dongfeng people ...

☆ "Moisture against the sky" attracts Huanglongshui

☆ "We have to get out of the car with our teeth!"

☆ Rao Bin Squat Point Engine Factory

☆ "Iron Girl" can build "half of the sky" in Ebast.

☆ The statue of Chairman Mao in the first furnace of the second steam

☆ She "settled" for the movie screener

☆ You can do it! 75 -day car building is not a dream

☆ How to draw drawings at the beginning of the Erqi Construction Factory?

☆ More than fifty years ago, what was the driver experience in 2.

☆ How did a car manufacturer built soy sauce?

☆ That year, he embarked on the first scene of fighting for Elvanian entrepreneurship

☆ At that time, the most advanced engine laboratory in the country was in Erqi!

☆ In order to set up a reed shed, he even experienced these ...

☆ We want to give Ebuka Movie movies!

☆ Code 5744! Do you know the first well here?

☆ More than a hundred people are divided into watermelon.

☆ Lujiagou used Danjiang Electricity

Edit: Zhang Zhe Chen Siyu Yinqi review: Zhou Liqin

- END -

The champion team racer tests Wuhan new track: I don’t have to go to Shanghai to train in the future

The Yangtze River Daily Da Wuhan Client August 5th (Reporter Gong Ping Correspondent Zhang Mo) On the 5th, Zheng Yue, a racer from the East Wind Magnar Team at the National Intelligent Connecting Moto

Disassemble the Ningde Times Kirin battery industry chain Who will drink new technology "head soup"?

30junText |Recently, the release of the third -generation CTP technology in Ningde...