15,000 "producers" in Chengdu: Epidemic prevention and insurance supply two hands to help the stable economic development

Author:Cover news Time:2022.09.18

Cover reporter Ma Mengfei

On September 17, the reporter learned from the Chengdu High -tech Zone that at present, there are 55 industrial enterprises in the regulations of the biomedical industry in the area of the biomedical industry, and the regulations of industrial enterprises have a re -work rate of 100%, and the overall production capacity release rate is nearly 90%.

Since the 15th, most areas of Chengdu have gradually returned to normal production. As a microcosm of the biomedical enterprise in Chengdu High -tech Zone, as the tide of re -production and re -production of Chengdu enterprises, it shows the strong toughness and surging vitality of Chengdu enterprises. With the gradual recovery of fireworks in Chengdu, at present, major factories and leading enterprises have also begun to adjust the previous "epidemic prevention bubble" closed -loop production model, further promote production progress, improve production efficiency, and help Sichuan's stable economic development.

As of September 16, Chengdu had a closed -loop management and continuous production of 15,000 companies in Chengdu, and 754,000 employees were provided by factories as the home and war. Looking back at the passage of this round of epidemic, this company that has opened a closed -loop production model of "epidemic prevention bubbles" is both a "warrior" and a "producer", which has contributed to the normal operation of the city and the economic and social development.

Standing on the node of "unblocking and recovering", do not forget the time to come, so as to stay steady.

More than 4,300 people in factory production

From 800 cars in Nissan to 1300 units

On September 18th, in the FAW-Volkswagen Chengdu plant located in Longquanyi District, in the bright factory, accompanied by a new car offline, workers carefully checked each car. After two weeks of operation in the closed -loop production model, as the city resumes the order of production and life in an orderly manner, the factory has gradually returned to normal.

"The plan and order volume formulated by the company at the beginning of the year has not changed. It will sprint and find a way to recover the lost output." The relevant person in charge of FAW-Volkswagen Chengdu Branch introduced to reporters that one car is offline every 56 seconds, one one, one one, one The cars on the world gradually returned from the beginning of more than 800 units to more than 1,300 units. The Chengdu plant is the first vehicle production base built by FAW-Volkswagen in addition to Changchun Headquarters. It is also the highest production capacity planning factory outside the headquarters. It has a vital impact on the realization of FAW-Volkswagen's annual production and sales target.

FAW-Volkswagen Chengdu is full of horsepower production

"The epidemic in Changchun and Shanghai in the first half of the year had a certain impact on the entire automobile production and supply chain. At that time, the Changchun headquarters carried out a period of closed -loop production. From the perspective of risk estimation, the company also formulated the closed -loop production plan of the Chengdu plant. ", The above person in charge said. Therefore, since September 1st, FAW-Volkswagen Chengdu Branch has quickly launched the plan for closed-loop production. On the premise of doing a good job of preventing and controlling the epidemic, it is necessary to ensure that production and operations are continuously line. During the period, the largest production units in Longquan District.

Data show that in 2021, the output value of Longquanyi Automobile's manufacturing industry reached 155.4 billion yuan, the output of the entire vehicle accounted for 97.7%of the city, and 89.6%in Sichuan Province. Therefore, the normal operation of automobile factories is the prerequisite for ensuring the development of the industry.

It is understood that as a "chain owner" enterprise in the automotive industry, FAW-Volkswagen Chengdu Company has also improved the inventory level of parts before this closed-loop production, and the company has also improved the inventory level of the components and prepared for at least two weeks in advance for at least two weeks in advance. Production materials, "There are nearly 90 suppliers in the local area, which is also producing closed -loop, so it guarantees the stability of the overall production." The person in charge said.

Data show that from September 1st to 13th, FAW-Volkswagen Chengdu Branch has produced a total of 12,889 vehicles.

More than 1800 people maintain the production capacity above 96%

Guarantee supply of product supply in more than 40 countries and regions

On September 15, most parts of Chengdu ushered in "unsealed". In the factory area of Sichuan Kelun Pharmaceutical Co., Ltd. (hereinafter referred to as "Kelun Pharmaceutical's New Metropolitan Base"), with the tension and rhythmic operating sound of automated machinery on the assembly line, a bag of infusion products slowly slowly from the conveyor belt. Sending it, the staff was inspecting the product.

Caren Pharmaceutical New Metropolitan Base Production Workshop

From September 1st, more than 1,800 employees of the new capital of Colom Pharmaceuticals have eaten and lived in the factory area, maintaining the production capacity above 96%. Today, the base has basically returned to normal production. "At present, the production capacity has returned to the level before the closed loop, and is going all out to organize production. The production tasks in September will definitely be excessive." Said Liu Wenjun, general manager of Kellen Pharmaceutical New Metropolitan Base.

As a large -scale large -capacity injection production base in the country, it is also the first company in Kelun Pharmaceutical. Metaphor. According to Liu Wenjun, at the same time, the base also produces 5 episodes of collection, of which three varieties are currently less inventory, so we focus on the production focus on these three episodes.

In order to achieve a full load production, the new capital base of Columbia Pharmaceuticals combined with the product structure and the urgency of market demand, through adjustment of production plans and integrating production resources, and adopting a scientific combination production method to achieve the expected capacity goals.

"After experiencing electricity tensions and the impact of the epidemic, it has also brought some inspiration to the enterprise." Liu Wenjun said that as a pharmaceutical material guarantee enterprise, in the future, how to adjust and reasonably arrange power consumption in the comprehensive energy layout, and carry out centralized energy reserves. The direction of considering and layout in the next step. At the same time, some measures and measures that should be taken to be taken in closed -loop production will also carry out some emergency drills and preventive work in the future. Improve production equipment in closed -loop production

Go all out to supplement the market blade consumption

On September 18th, in the Chengdu Bangpu cutting knives Co., Ltd. (hereinafter referred to as "Bangpu Knife") in Chengdu, Chengdu City, in the production workshop, a pile of metal powder was stamped and cut, and eventually it turned into it. An important blade parts in industrial mother machines. At present, the company has returned to normal production and operation.

Bangpu knife production workshop

Bangpu's tools are a company that has been engaged in precision CNC blades and mechanical processing scientific research and production for a long time. It is a high -tech enterprise identified by the Sichuan Provincial Department of Science and Technology and a national specialty new "little giant" enterprise.

He Junlin, deputy general manager of Bangpu knife, introduced that during the epidemic, the company had a large amount of orders because precision blades were consumables in the industry. All downstream companies demand this. The output is still different, "So we propose a plan to" grab time and grasp the progress ", and drive the previously delayed orders back."

In He Junlin's opinion, comprehensive re -production and re -production not only need to restore the production time of personnel, but also the top priority to improve production efficiency. In this regard, he said that Bangpu's tools began to build a precision knife intelligent manufacturing production line for the construction of key components of aviation engines in 2018. It was not until this year that it was fully built and used, but the production line was still in the running -in process. During the closed -loop production period, the staff improved the production line equipment while ensuring production. "According to the actual operation, we optimized some software and improved the efficiency of about 15%, which is very helpful for production." Bangpu. The person in charge of the tools related to the tool said.

"We provide a large number of tools for engine parts and accessories in the aviation industry. In this segment, the supply of the market reaches about 30%. Insufficient supply will have a certain impact on the market. "He Junlin said that due to the responsibility for downstream customers, the company must also go all out to ensure production and complete the supplement of the market blade consumption.

(Figure, the interviewee)

- END -

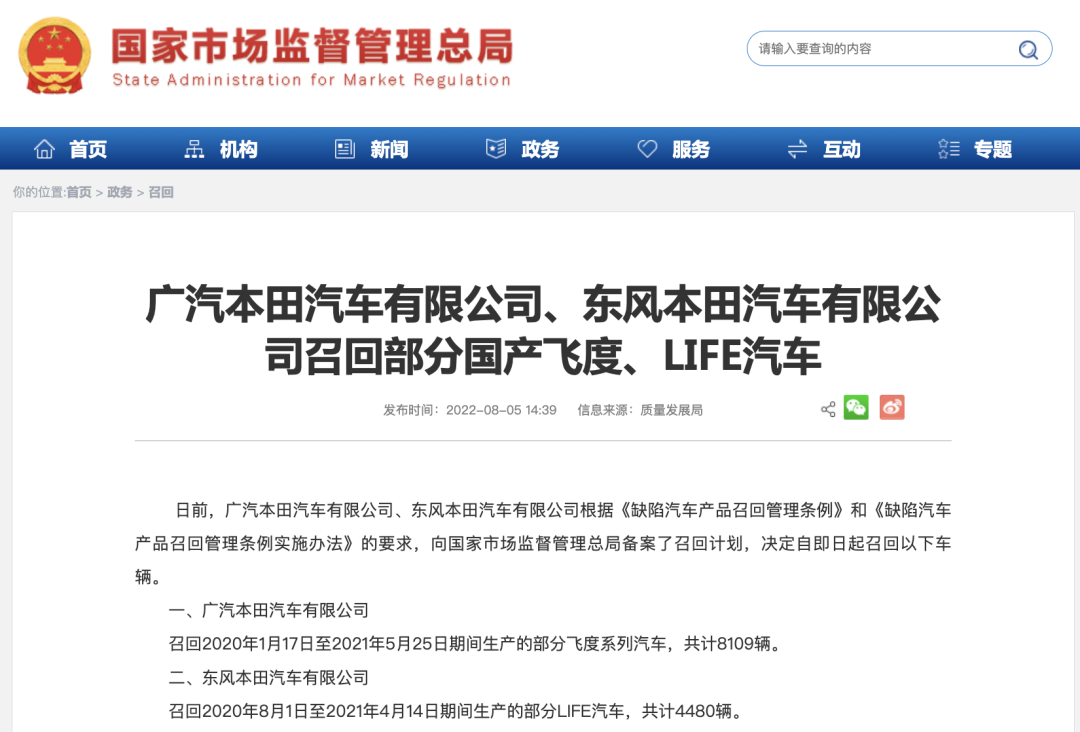

Emergency recall!Involved in GAC Honda, Dongfeng Honda, Mercedes -Benz, Peugeot Citroen

recentlyThe State Administration of Market Supervision and Administration issued t...

The 17 -year -old teenager rode a motorcycle to take two friends to play, but turned over ...

Every holidayUdrity increased in minorsIndividual parents are negligible to monito...