The chip delivery cycle has narrowed for the third consecutive month, but there are still car companies to stop production.

Author:Daily Economic News Time:2022.09.21

Although global chip supply is recovering, some car companies are still experiencing "lack of cores".

According to Reuters, a few days ago, the union representatives of Stellandis Group and Renault Group said that due to the shortage of chip shortage, the two companies will suspend the production of some of the assembly lines in the Spanish factories in the next few days and even a few weeks. Among them, Renault will temporarily stop production in two factories in Castilla and Lyon, Spain, one of which is completely closed on September 17, and the other will cancel the rotation shift in the few days this week and next week; and the other will be canceled this week and next week. Stellandis canceled the night shift from September 17th to 18th in Victoria's factory in northwestern Spain.

According to Germany's "Auto Weekly", Murat Aksel, the procurement director of Volkswagen, said that the shortage of chips is expected to end in 2023, and Volkswagen is preparing for the "new normal" of the supply chain interruption.

The good news is that although some types of semiconductors are still tight, the shortage of global chips is further relieved. Research data from Haina International Group show that the average global chip delivery cycle in August (the time from the chip from ordering to delivery) was 26.8 weeks, which was shortened by one day from the average delivery cycle in July and narrowed for the third consecutive month. Since the beginning of this year, the Semiconductor Index of the Philadelphia Stock Exchange has fallen by 33%.

"The current shortage of chips of multinational car companies is mainly because of insufficient supply and poor industrial chain." Cui Dongshu, secretary general of the National Passenger Vehicle Market Information Joint Association, said in an interview with the reporter of "Daily Economic News" that "the chip of the automotive industry The shortage of shortage should be relieved by the end of this year. "

A joint venture brand dealer told reporters that at present, there is no situation in the store where the "core" affects the delivery of the model. The car pick -up cycle of each model does not affect terminal sales.

The shortage of chip is still "blockbuster"

In fact, Renault, Stellandis, etc. have to suspend production due to "lack of cores", which is not an example in the current automotive industry.

As early as the end of August this year, Honda Motors stated that due to the shortage of components such as semiconductor, the influence of the epidemic spread, and the stagnation of logistics, the output of Honda in Japan in early September will decrease than the original plan. Among them, the two production lines of the Suzuka Factory in western Japan will reduce the output by about 30%in early September. The Saitama Prefecture Factory in northern Tokyo will also reduce the output in early September, including Fit, Binzhi and other, including Fitness, Binzhi and so on. Many models will be affected by production reduction. At the same time, due to the reduction of production, the supply period of some Honda models has been extended to about 5-6 months.

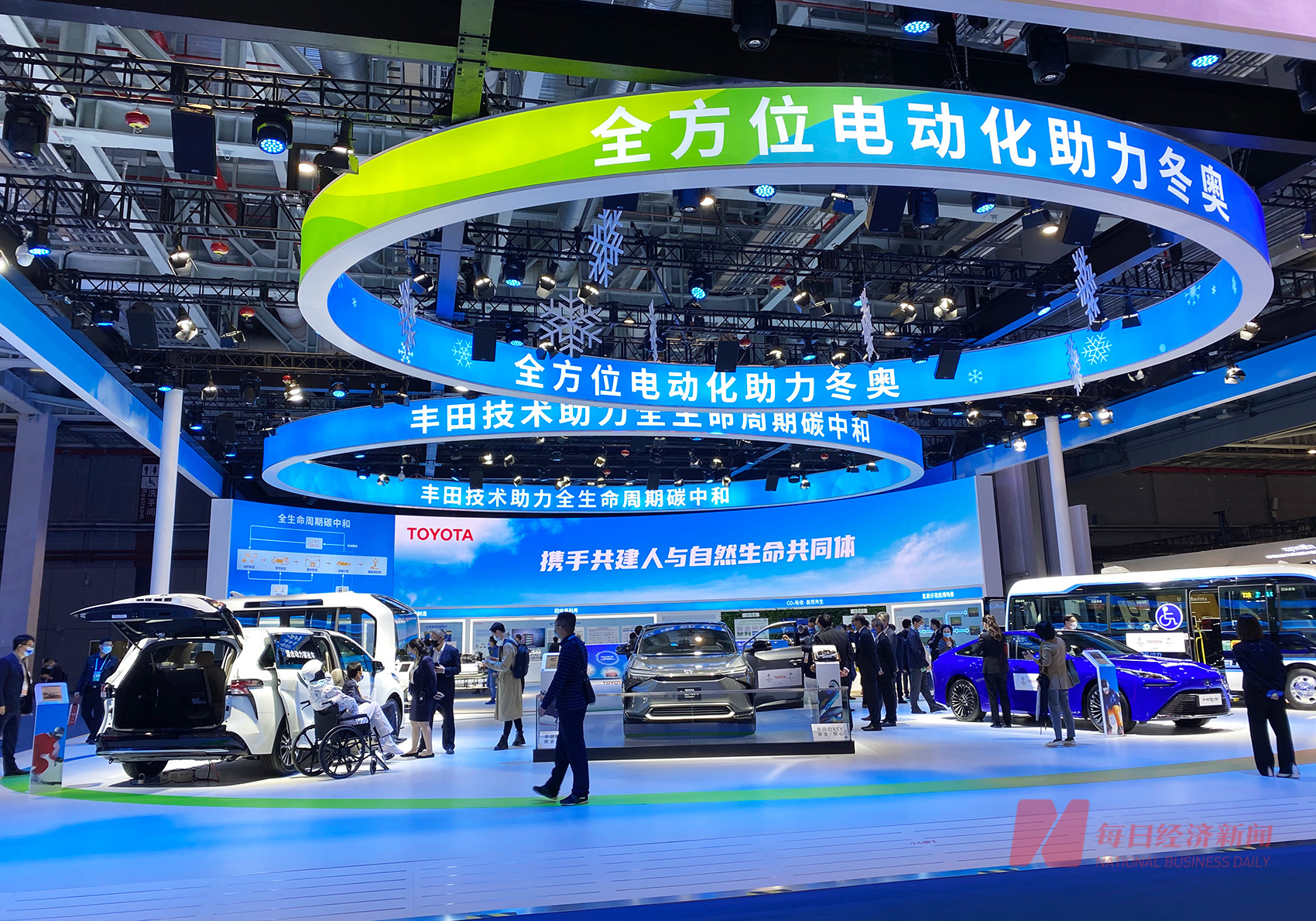

In addition, since this year, Toyota Motors has adjusted Japanese local production plans many times. One of the reasons is the shortage of components such as semiconductors. During the adjustment of the production plan in September, the three production lines in the Yuancho factory planned to suspend production from September 1st to 2nd, 5th to 6th, 26th to 30th. , BZ4X, Lexus LC, etc. However, Toyota is expected to have an average monthly output of 900,000 units from September to November, which is increased from 8 to October's monthly production plan.

Photo source: Photo by reporter Huang Xinxu (data map)

"Semiconductor shortage is a structural problem that cannot be solved so quickly. As geopolitical issues appear, this problem will become more complicated and challenging. According to the situation we see in the supply chain in the past two years, This is the new normal. "Murat Aksel believes.

According to the latest data from Autoforecast Solutions, the automotive industry data forecast company, as of September 4, due to chip shorts, the global automotive market has reduced production by about 3.1561 million units this year. It is expected that by the end of this year, the cumulative reduction of the global automobile market will climb to 3.9951 million units.

Since the beginning of this year, many domestic car companies have been troubled by "lack of cores" and even discontinued. In June of this year, Chen Yudong, president of Bosch China, publicly stated that Bosch's chip products can only meet the needs of 31%of car manufacturers on average. It is expected that the supply rate in the second half of the year can be increased to 50%to 60%. Essence

Zeng Qinghong, chairman of GAC Group, said that in the first half of 2022, due to chip shortage and affected by the epidemic, GAC Group reduced production by 160,000 units, with an output value of about 20 billion yuan. In the second quarter, the chip shortage was as high as 33,000.

However, from the current terminal situation of the domestic auto market, the "core" situation has gradually eased. A very much brand sales staff told reporters: "At present, the delivery speed of the new car has come up, and I have not heard that the delivery of the delivery due to the shortage of chip. However, Ji Yan has always had a order The car may need to be next year. "

Domestic chips ushered in excellent introduction opportunities

Although the structural supply gap still exists, the industry generally believes that the overall core lack has been relieved.

Zhu Lin, a researcher at Wanhe Securities, believes that since September 2020, under the influence of the mismatch of supply and demand, the electronics industry has experienced changes in the volume and price relationship of "chip shortage-structural waste-inventory". The decline in the time of delivery and the high industry inventory basically verified that the electronic industry has entered a downlink stage as a whole, and the overall lack of cores has been relieved.

On the other hand, the inventory of large -scale semiconductor companies has returned to the level before the epidemic. The average number of inventory weeks in 2022, including Ruisa Electronics, Germany, Germany, Enshipo Semiconductor, Swiss Semiconductor Semiconductor, Swiss Semiconductor Semiconductor, and Swiss Semiconductor Semiconductor. )Flat. This also means that the semiconductor supply began in the second half of 2020 is improving, which helps to recover production such as vehicle companies. Photo source: Photo Network-401116818

Crisloland, an analyst at Heine International Group, also believes that the shortened chip delivery cycle reflects the market's demand for certain technology products is cooling. When the delivery period is shortened to 10-14 weeks, the supply and demand of the chip market will enter the "health" state.

"The level of electrification of new energy vehicles is high and has more functions. The number of chips of bicycles is also more than traditional models. With the rapid growth of new energy vehicles, the demand for chips has continued to expand. At the same time The transformation also brings more chip demand. In addition, the influence of factors such as the epidemic, the production capacity of the chip company itself has been restricted. These factors have comprehensively caused the supply of automotive chips. "Jiangxi New Energy Technology Vocational College of New Energy Vehicle Technology Zhang Xiang, Dean of the Institute, told reporters.

It is worth noting that in the context of the structural gap of the chip, domestic chips have ushered in new opportunities. On September 18, Yang Xudong, deputy director of the Electronic Information Department of the Ministry of Industry and Information Technology, said at the 2022 World Intelligent Connected Auto Conference that automobile chips and software have become a key technical support for the transformation of the automotive industry. Further pay more attention to and support the innovative products of chip companies, and strengthen the construction of a diversified supply chain.

In its research report, Debon Securities believes that the recovery time of the chip supply chain is uncertain, and the lack of cores causes the downstream demand party to choose domestic manufacturer products to solve part of the urgent urgent need, providing excellent introduction opportunities for domestic chip companies, and obtaining customer verification and passing. After a large scale, domestic chip manufacturers will further consolidate their industry status and achieve a higher localization rate to continue the trend of localization.

However, Miao Wei, deputy director of the Economic Commission of the National Committee of the Chinese People's Political Consultative Conference, believes that vehicle -level chips have higher requirements than consumer -level and industrial -grade chips, longer certification time, and higher thresholds for getting on the car than consumer -level. Under the premise of globalization, it is not scientific or economical to seek "100%autonomy" in the fields of chips and other fields. "We welcomes foreign vehicle companies, foreign chip companies, and foreign software companies to invest in China to share with us with us. , But it is also necessary to form independent capabilities. "Miao Wei believes that car companies should plan ahead, bear the responsibility of" chain leaders ", and do a good job of taking the lead.

Daily Economic News

- END -

There is an electric bicycle at home!This matter must be done!

Zhejiang News Client Reporter Quan Linxun Correspondent MarketIn order to ensure t...

Drive the recovery of the CCTV car consumption, the 3022 Dahe International Auto Show successfully concluded

Dahe Daily · Yu Video Reporter Xie Yuanli Shi Shi Geng Zi Tenghong, Wanqiyi Inter...