Microcar -level deformation at 1200 ° C, the Wan testing group becomes the leader of the industry

Author:Changjiang Daily Time:2022.06.19

Hubei Wan Test Equipment Co., Ltd.. Reporter He Xiaogang Photo

The Yangtze River Daily Da Wuhan client June 19th News At a high temperature of 1200 ° C, it can accurately measure the micron -level deformation of various materials. Recently, in the R & D and manufacturing base of the Jiangxia Economic Development Zone, the reporter from the Yangtze River Daily saw that various mechanical performance measurement and testing equipment was full of exhibition halls. The drop hammer impact test machine is all available. "It is no exaggeration to say that our equipment is more complete than the national laboratories in some countries!" Huang Xing, the person in charge of the company, proudly introduced to reporters. Since Jiangxia was put into production in 2020, Wan test has become a leading enterprise in the field of mechanical performance testing equipment in the country, with an annual output value of 320 million yuan in 2021.

Established in 2011, it is a national high -tech enterprise that integrates professional mechanical performance testing to solve the research and development, manufacturing, sales and service of technical solutions. It is also a national "specialized new" enterprise. The testing machine produced by its production is used for mechanical testing in various materials fields. It includes both the commonly used steel tension test machines or dynamic fatigue test machines, as well as mechanical testing equipment of composite materials under various types of high and low temperature conditions.

Deep plowing mechanics testing field

Focus on solving industry problems

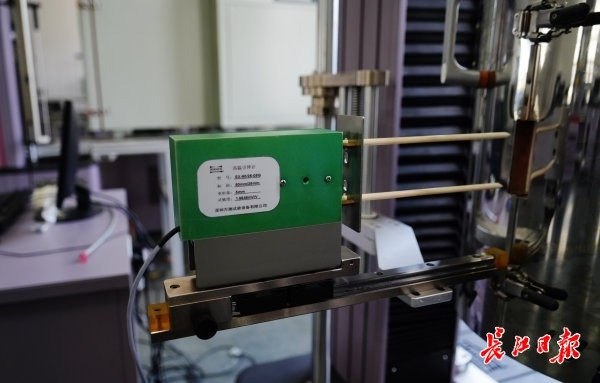

High temperature extension. Reporter He Xiaogang Photo

A box of about 20 centimeters long and 10 cm wide extended two slender ceramic stories from the inside. It can accurately measure the micron -level deformation data of the test material in thousands of degrees of high temperature. This type of test has extensive demand in the field of aerospace and nuclear industry. This year, the high -temperature extension of Wancai's production is the first high -temperature extension with completely independent intellectual property rights.

Huang Xing, who graduated from Huazhong University of Science and Technology for more than 20 years in this field. He told reporters that the R & D team spent about 10 years before and after the development of this high -temperature extension, during which the number of times was stagnant due to the technical card shell. Last year, after years of continuous research and development and technological research, Wan Testing made breakthroughs in the internal structure of the device, and finally successfully developed and invested in the market.

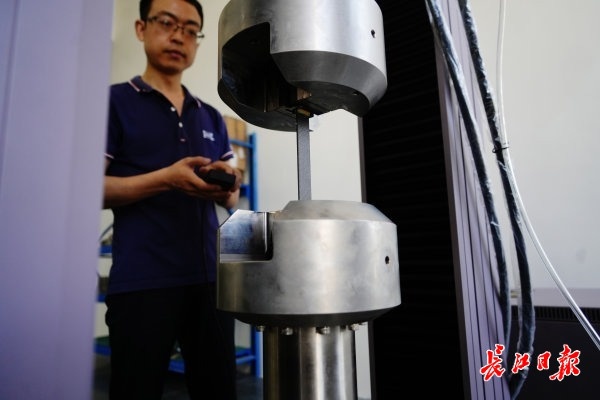

Engineering and technical personnel are debugging the mechanical testing equipment for composite materials. Reporter He Xiaogang Photo

According to Huang Xing, in fact, this device has little direct economic benefits for universal testing. The main products sold by the company are generally from 100,000 yuan to one million yuan. However, this product can be widely used in key areas such as aerospace and nuclear industry. This high -precision testing equipment has special significance for the manufacturing of high -precision products in my country.

Today, in the fields of high -temperature testing, composite materials testing, and automation applications, all tests are at the forefront of the industry, and have participated in more than 50 industry standards to formulate and revise and have more than 200 patents. At present, there are R & D and manufacturing bases in Wuhan, Shenzhen, Shanghai and other places.

The third phase of the R & D base started construction

Optimistic about Wuhan's advantages continuously adding investment

Various mechanical performance measurement and testing equipment is full of exhibition halls. Reporter He Xiaogang Photo

In the Wan testing Wuhan R & D base, a composite material testing equipment that is being developed and prepared to be put into production is also the pride of Huang Xing and colleagues in teams. "It will be a new breakthrough in domestic composite material testing equipment."

According to reports, most commonly used steel -resistant tensile strengths are mostly 500 MPa to 1,000 MPa, which requires not high requirements for detection equipment. And this device can perform stretching tests in high and low temperature environment for carbon fiber composite materials with a intensity of more than 3,000 MPa. "These composite materials will be used for products such as domestic large aircraft, which is very valuable for the development and quality control of China's independent composite materials."

Engineering and technical personnel are doing mechanical testing for composite materials. Reporter He Xiaogang Photo

At present, the third phase of the Wanshou Wuhan R & D and Manufacturing Base of 15 million yuan has started construction this month, and plans to build the first production plant in China to produce 11 -meter high test machines. In addition, the base also has 8,600 square meters of R & D building, and the established Wancai Wuhan Testing Machine Research Institute is also among them.

"Wan tested in Wuhan is exactly the talent advantage here." Huang Xing introduced that in 2019, after nearly 10 years in Shenzhen, the founder team of Wan test came to Wuhan for new development opportunities. In the previous year, the sales of Wan tests exceeded 200 million yuan, becoming a leading enterprise in the industry, and urgently needed more R & D talents and development space.

At that time, the construction of the land, the construction of the major universities in Wuhan every year, recruited professional counterpart talents, output value and sales to increase year after the future ... Back to the development process of entering Wuhan, Huang Xing believes that the decision -making of Wan test is correct, "especially In terms of talents, high -quality graduates enter enterprises every year, which is very critical for companies such as we focusing on technology. " Huang Xing said that in the future, Wan test will build a leading industry in Wuhan and the world's top R & D team.

Changjiang Daily reporter Wang Yan Chen Yu Correspondent Liu Yang Tian Yong

Video, photography: Reporter He Xiaogang

【Edit: Ding】

For more exciting content, please download the "Da Wuhan" client in the major application markets.

- END -

This "next set meal" is warm!awesome!

New and old, mutual integrity and calmnessThe guidance of the organs is difficult ...

20 pilots, the plateau first flying

Text 丨 Huang Peng, Huang Xinglei, Li SichengThe rotor roar, the war eagle array. ...