They dream of using intelligence for production quality

Author:Changsha University of Technol Time:2022.09.24

——Re Remember the 24th China Robotics and Artificial Intelligence Competition National First Prize, Changsha University of Technology "High -precision Pharmaceutical Packaging Packaging Development System"

(Correspondent Li Linqing Yulan) Changli in mid -July was a little more peaceful than usual, and most of the students had already gone home on vacation. In the laboratory of the Science Building, a student innovation team is surrounding the experimental equipment to collect, record, and analyze experimental data ... Even if they are late at night, they are on the way back to the dormitory from the laboratory. Experimental results.

They are members of the first prize of the China Robotics and Artificial Intelligence Contest of the 24th China Robotics and Artificial Intelligence Contest of Changsha University of Technology. Professional Sun Zhaowen and 2018 Telecom, Liu Xiaoguo, are not the first time they have stayed in school for the first time because of innovation competitions.

Research and development of demand

Whether the drug packaging is intact is very important for the drug's efficacy. Because the packaging of aluminum -plastic bubbles has the characteristics of light quality, perspective, and easy to use, most commonly used medicines are packaged in this form, such as tablets and capsules such as solid preparations such as tablets and capsules.

However, the "High -precision Pharmaceutical Package Packaging Defective Inspection System" team found that the current detection of domestic drug packaging is mainly based on traditional artificial testing methods. Compared with foreign countries, there is a large gap between foreign countries and prone to misunderstanding and missed inspection. "In recent years, empty granules, defects, and pill flaws will occur in the production of medicines, which will affect the quality of medicines." During the traditional artificial packaging quality testing process, due to the large number of drugs on the assembly line, and the noise in the production workshop, the production workshop noise noise The reflection of interference and drug packaging can easily cause the visual fatigue of workers, making unqualified products a "fish that missed the net". They decided to let the machine vision help the workers.

"In short, our research system is to collect the already packaged drug images that have been packaged on the full -automatic bubble packaging machine, and then analyze the structure, geometry, color, texture and other defects of the imaging drugs." Liu Xiaokuo said that the system utilization Machine vision combines image detection technology and defect detection technology to find and eliminate unqualified products to achieve the purpose of detection and screening.

At present, their research results have been tested in relevant pharmaceutical plants, and they can accurately detect 8 types of defects in the production process. The total defect detection accuracy rate is 99.66%, and the detection time is less than 115 millisecond/board. The requirements for testing indicators have increased by about two percentage compared with the national industry standards and the most advanced products in the same industry in the same industry, so as to reduce costs while reducing costs.

"In fact, the technology application of this system is not limited to pharmaceutical packaging." Sun Zhaowen said that machine vision involves cross disciplines in many fields such as artificial intelligence, physics, computer science, image processing, biology, and model recognition. In industrial production, it can also be applied to the quality testing of agricultural products. "Therefore, machine vision has a lot of room for research and development in the field of defect detection."

In the future, their research will also radiate food packaging and cosmetics packaging. "Because there are still many variables in the process of actual large -scale production and use, we will continue to adjust the system and strive to transform what we have learned into productivity." Liu Xiaokuo said.

"Doing scientific research must be sinking"

"The biggest difficulty in the competition is that the grasp of the scoring direction and the focus is not accurate enough, resulting in many key points at the beginning." Sun Zhaowen recalled. To solve this problem, they improved and polished the project over and over again after the help of the teacher. Teachers also improve their response capabilities by simulating experts on the spot.

This competition adopts the form of online connection judges. Compared with live demonstrations, the effect of the video display is not intuitive enough, and the impression is not deep enough. The problem.

"The person who wants to thank the most is Teacher Tang Lijun and Teacher Wen Yongjun. They have been urging us to continue to modify our works to make up for the lack of video display. Without their careful guidance day and night, there is no our success. Of course, it is also left to leave. No unity and cooperation with teammates. "Sun Zhaowen's words came out of their hearts. The teacher's guidance and teammates' collaboration were the helping device on their growth.

The three members of the team come from different colleges, different majors, and different grades. Not only their respective knowledge are different, but the way of thinking is different, let alone the strangeness of the first cooperation. The first challenge. "I did not expect that the first Land Rover did not originate from scientific research problems nor derived from technical operations, but was different from 'innate'." Liu Xiaokuo joked.

The first few months was the running -in period of the new team. From time to time, they eat or drink milk tea together, release pressure, discuss the problems encountered in the experiment in a state of not tight thinking, or understand each other's strengths through chat, and make up for their strengths. Between a meal and a cup of tea, they transformed the shortcomings of "different" into a unique advantage.

The three trained tacit understanding during the running -in period and found a positioning suitable for them: Ning Qian, a computer major, is mainly responsible for the theoretical design of the project, completing the module such as soft technology such as image algorithms; Responsible for the use of theory to reality, implementing the actual operation of the installation and commissioning of hardware equipment. Everyone in the combination of soft and hardware, the theoretical design and actual implementation of efficient collaboration. The three of them slowly learned and continued to explore. In addition to their own responsibility, they also learned a lot of teammates' knowledge, while deep development and extensive learning.

The debugging assembly of the device is another difficulty they encountered. Because the drug needs to perform defect detection and classification on the conveyor belt, this requires finding a proper matching time in multiple links such as combined light sources, image processing, and exclusion. The difficulty is that it can only achieve the overall coordinated control of the system by debugging the task scheduling of each module and the time point of operation.

"To achieve the best results, it is necessary to complete the operation of image collection, image processing, classification exclusion, etc. in a short period of time." After repeated experiments in cooperation and collaborative control between modules, the test finally made the detection detection. The equipment has achieved the best effect in terms of accuracy, accuracy and efficiency. "Doing scientific research is to sink and find the best solution in repeated experiments."

Continue to adhere to the road of scientific research

In the winter vacation last year, the team members chose to stay in school for experiments during the holidays, and they did not go home until they were approaching by the New Year of the lunar calendar. "There is a more atmosphere of studying at school, and I will feel less when I go home." Sun Zhaowen explained. But even if he returned home, he couldn't help it, and it took a lot of time to think about how to better improve the ending device at the end of the equipment.

In order to study more time, they went out early and returned early, and their roommates were infected in their eyes. Sun Zhaowen's roommate Cao Yang said: "There is an excellent roommate that can drive the learning atmosphere of the entire bedroom. His energy in scientific research has also increased our interest in scientific research."

The new semester has arrived, and the team's research results have achieved good results in the competition. The team members have also started the study of the new journey. Sun Zhaowen and Liu Xiaokuo are already first -year freshmen in Changli, and Ning Qian is preparing for the postgraduate entrance examination. "We first walked into Teacher Tang's laboratory with a mentality of learning. During the research of the project, we also slowly deepened our understanding of scientific research and strengthened our determination to continue research."

On the road of scientific research, there are not only cold machines and equipment and silent data, but also the teacher's guidance and care, the collaboration and companionship of teammates, and the blood in my heart. From the opinions of Sun Zhaowen, Liu Xiaokuo and Ning Qian, their own scientific research has just begun. In the future, they will continue to study and strive to realize the dream of "serving the society with science and technology and using intelligence to improve quality."

- END -

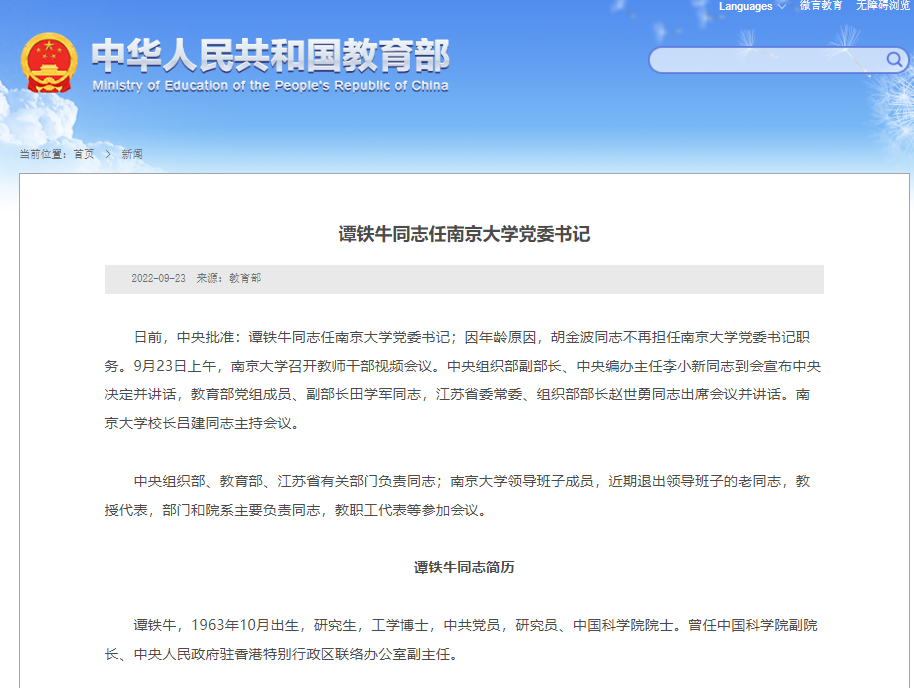

Heavy!Academician of the Chinese Academy of Sciences, served as Secretary of the Party Committee of C9 University University

A few days ago, the central government approved: Comrade Tan Tieniu served as the ...

"29 people and 24 people in the class successfully read the study", where did the remaining 5 people go?

29 people and 24 people in the class successfully studied. Such a class rushed to ...