The front page of the Workers' Daily: Why is FAW's busy production site "quiet"?

Author:Jilin Radio and TV Station Time:2022.07.20

Facing Chaoyang into the factory area of FAW Liberation Automobile Co., Ltd. (hereinafter referred to as FAW Liberation), through the old building complex of the 1950s, a blue glass curtain wall shines in the sun World -class commercial vehicle intellectual base: Jiefang J7 Smart Factory.

From one hammer and one -chisey, the first car in New China -Jiefang CA10 truck, to this day, independently developed the seventh -generation model -the main intelligent high -end heavy truck J7, in 66 years, FAW Liberation from chase to leading leadership to leadership From "manufacturing" to "intelligent manufacturing", China ’s heavy truck sales have achieved the global“ five consecutive championships ”and heavy card sales global“ six consecutive championships ”, reflecting the development of the Chinese automotive industry.

The robot completes the assembly "Xingyun flowing water"

In the new J7 vehicle smart factory, which surprised reporters, the first was the quietness of the production site. There were no roar, no dense workers, and in the spacious and clean workshop, all kinds of robots were busy silently.

"Various pneumatic tools in the old factory buildings are banging, and the forklifts, traction vehicles such as delivery of logistics, and solemn are loud, and they have to speak." Workers told reporters happily that in the new smart factory, electric tools replaced the pneumatic tools in large quantities of pneumatic tools. In particular, the entire logistics uses the handling robot AGV, and the automatic unmanned distribution is "quiet".

Pick up tires, flip, put down, place in place, tightened ... In the corner of the workshop, the first assembly robot in the global commercial vehicle industry is running before running, and cooperates with different AGVs and closely cooperates. The car body installation tires, the whole process is flowing and flowing -this is the "full automatic accompanying assembly" of the J7 Smart Factory.

"Earlier, the best way in the industry was to assemble at a fixed -point assembly, which was to park the car in a fixed position. Tires were installed by 6 robots. Our accompanying assembly was the side of the car. Exit, the efficiency is improved, but the cost is reduced. "Wang Yiqiang, director of the Intelligent Equipment Workshop, told reporters that the technical difficulties during the period are not only to ensure the absolute tacit understanding of AGV and the assembly robot, but also require robots to have high -precision positioning capabilities. In the process of being accompanied by the same frequency as AGV, it is necessary to overcome spatial obstacles, quickly and accurately install all tires and automatically tighten the nuts of different specifications. Multiple links need to apply visual recognition technology.

Not only the tires are fully automatic with each other, the J7 smart factory also integrates a number of industry -first technology, such as the vehicle ECAS intelligent online calibration, automatic frame unloading and intelligent marshalling, functionhole position smart laser engraving ... operational production efficiency is more traditional than traditional than traditional The truck production line is increased by more than 10%.

"We can say very confidently that the FAW Jiefang J7 OEMs Smart Factory represents the integration and strength of China's most advanced automotive manufacturing technology." Wang Yiqiang proudly said that every technical breakthrough of this smart factory is the result of a wide range of benefits and benefits Essence

The three major systems constitute "the strongest brain"

"Why is it a smart factory here? In fact, relying on the latest digital technologies such as the Industrial Internet and Big Data, the information control system that supports the supporting role in the background is the true charm of the J7 Smart Factory." Engineer Yan Wenlong said.

It turned out that the logistics execution system LES, the process execution system DPS, and the manufacturing execution system MOM, these three key systems interconnected, together constitute the "strongest brain" of the J7 new factory.

Walking in the workshop, the reporter saw that in the air, the mechanized transportation was large parts such as tires, seats, engines, gearboxes; in the corridor, hundreds of AGV cars were automatically found to transport small parts to various production nodes; the ground on the ground; ground On the top, the line body AGV shows the extension, but the body is not obvious, but it is amazing. It can easily hold the J7 car body weighing about 6.8 tons on the production line. They are three -dimensional distribution, each performing their duties, and the "logistics commander" LES is regulated and controlled, and the "concerto" of the fully automatic unmanned distribution is played together.

The number of parts of commercial vehicles is two or three times more than the passenger cars, and the product types are richer. Which parts need to be delivered to which parts are provided by the DPS system for LES in real time. For example, LES receives the over -point information sent by DPS to "assemble bolt bolts at the fifth -site", and will immediately tell the AGV logistics vehicle to send the corresponding model's bolts to the 5th station. This automatic, time -time, accurate, and quantitative distribution has increased the operating efficiency of factory logistics by 55%.

Of course, providing logistics information data for LES is only one of the functions of the DPS system. Its main function is to pass on -phase process parameters to each station, and tailor different processing methods for different types of products. Process parameters are directly connected to the device and do not need to be manually set.

"The MOM system seems to be a central brain, and its function is more powerful. In short, with the close cooperation of LES, DPS, and MOM, many of the original content that needs to be manually operated will be transformed into intelligent and automated operations. The entire factory personnel decrease by about 20% The operating efficiency increased by 27%, "Yan Wenlong said.

Quality process 100%intelligent controllable

While the intelligent factory has greatly improved production efficiency, it has further ensured product quality.

"Automation and intelligence solve the problem of artificial assembly that cannot guarantee product consistency. It has fundamentally reduced the probability of errors, and the product is naturally more reliable." Wang Yiqiang said.

Taking the oil intelligent accompanying injection as an example, Liu Shuai, an on -site operator, told reporters: "In the past, adding oil to the oil by manual control may have less and leakage. , The system automatically enters the process parameters, and it is impossible to make mistakes. "For another example, high -end commercial vehicle chassis suspension structure uses airbags to shock, and 8 airbags should be assembled in the middle and rear bridges. It affects the shock absorption effect, so the distance between the frame and the ground must be calibrated during assembly. In the past, this was measured and marked by the workers on the spot. There were many errors. For the first time, the J7 Smart Factory implemented the "ECAS Online Intelligent calibration", which was automatically measured by laser. The online "second speed" calibration, almost zero errors.

In the J7 Intelligent Factory, each new car will automatically generate a unique electronic "ID card". There are both the production date of the car, the time of online and offline, the quality process information during assembly, and some components. Key information and so on. This is the "one car, one order" manufacturing model implemented by the factory. 100%intelligent controllable, traceable.

From design to the completion, it took more than 500 days to liberate the J7 vehicle intelligent factory. With so many technical breakthroughs, such a fast construction speed stems from the extremely deep historical accumulation of FAW's liberation. "As the eldest son of the Republic ', the goal of FAW's liberation is' China's first, world -class", we must not only pursue the first of product sales, but also achieve the first to manufacture technology levels. Define the automotive industry and lead the industry to create the future. "Wang Yiqiang said.

Original title: FAW Liberation uses "old brands" to lead "new intelligence manufacturing" to create a world -class commercial vehicle "smart manufacturing" base for the busy production site "quiet"?

Edit: Xiao Zhi

Source: Workers Daily

- END -

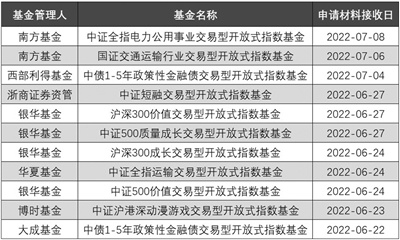

Layout the domestic ETF market in the field of the track continues to expand

On July 11, three Chinese medicine ETFs from the three fund companies of Penghua, ...

The first nationwide!Yunnan 17 ethnic minority traditional sports bases are officially awarded

DrawingDrawingYunnan Net News (Reporter Long Yan) In the fierce battle of the twel...