One "green" to the end!New theme

Author:China Economic Network Time:2022.09.13

The paper industry is the pillar industry of my country's national economy. Compared with the power generation, petrochemical, chemical, building materials, steel, and non -ferrous industries, although the papermaking industry accounts for a relatively low carbon emissions, my country's paper industry has a large dependence on resources. High energy consumption and difficulty in recycling of waste paper make the paper industry must take more powerful carbon emission reduction measures in implementing the national "double carbon" target requirements. Promoting green development has become an important direction for the development of the paper industry.

Fen Ouhuichuan (China) Co., Ltd. (hereinafter referred to as "UPM") Ms. Ma Yuanyuan, Director of Relationship Director of the Relations of Special Paper Paper, said, "As a member of the Chinese paper industry, UPM is promoting the green low -carbon and sustainable development of the Chinese paper industry in the Chinese paper industry The side has been actively exploring, not only the high quality of the product, but also paying attention to the environmental value of the product. As the world's leading forest industry enterprise, UPM actively responds to the call for environmental protection energy conservation and emission reduction, helping to create the future of transcendence of fossil energy sources. From forest carbon carbon Three aspects of Hui, Energy Conservation and Eatsurding, and low -carbon products contribute to slowing climate change. "

In the impression of most people, the paper mill is a large environmental pollution. The papermaking process will produce a large amount of solid waste. With the gradual expansion of the scale of the paper industry, the environmental impacts brought by these solid wastes are also increasingly prominent, and various ecological issues and social issues that follow. However, UPM adheres to the concept of green development, strives to minimize the environmental impact on the environment in all aspects of production, and actively seek the opportunity of sustainable development, and control pollutants and waste from the perspective of a full life cycle.

After years of exploration, UPM finds the two all the beauty of the two full beauty of fascination and cycle reuse -furnace slag can be used as a special brick material raw material for construction, and fly ash can be added to the concrete to improve the structure of the concrete. In 2021, the ash and slag of the UPM Changshu Paper Factory were reused in the construction industry. Moreover, UPM will follow up and confirm the fly ash and scum sold to the construction industry to ensure that the use of the terminal will not affect the environment.

The papermaking industry is one of the eight major industries in my country to include carbon transactions in China. Optimizing the industrial structure and energy structure, intelligent manufacturing and green upgrades are becoming an inevitable choice for the survival and development of the paper industry in the context of economic transformation.

According to Ma Yuanyuan, as early as 2013, UPM has begun to start carbon emission reduction projects. Calcium carbonate is an important raw material required for the papermaking process. It is used to increase the thickness of the paper and the smoothness of the paper. UPM Changshu Paper Factory cooperates with the calcium company to react with the processing of smoke and calcium hydroxide, and generate calcium carbonate as a paper filler. It not only absorbs the carbon dioxide discharged by the factory, but also provides raw materials for papermaking, and is also removed from the transportation process of calcium carbonate.

In order to achieve the "dual carbon" goal of the paper industry, the state has released a number of policies and put forward requirements from a macro perspective, such as accelerating the transformation and upgrading of the paper industry to improve the green construction system; encourage high -speed, large wide papermakers, and circular and low -carbon, low -carbon, low -carbon, low -carbon, low carbon Technical references, etc. For the papermaking industry, it is necessary to improve the use of resources and maintain the simultaneous development of the low -carbon economy in order to enhance the capacity and efficiency of enterprises and enhance the competitiveness of enterprises.

As a large paper factory, the fiber content of the waste pulp and sludge of the UPM Changshu Paper Factory is relatively high. According to this feature, because of the potential guidance with the construction industry supplier, UPM uses the waste paper sludge sludge as the raw material of the building material to produce a marble packaging Paper and interval paper raw materials to achieve regeneration. In 2021, about tens of thousands of tons of sludge became a treasure, becoming an important raw material for the construction industry.

Data show that since the new paper machine was put into production in 2016, the UPM frequency cooked paper factory has reduced 21%of water consumption, 47%COD (chemical oxygen demand) emissions, 11%carbon dioxide emissions, 62%acidic gases of 62% Eat emissions, craft waste reaches zero landfill. With its outstanding performance in the field of sustainable development, UPM has won the honor of national "green factories" and "water efficiency leaders", becoming one of the demonstration benchmark companies that help the green transformation of the paper industry.

"Forests are the source of paper products and raw materials. We love the forest carefully and operate the forest with sustainable concepts." Ma Yuanyuan said, "Fenouhui UPM Group grows 50 million trees worldwide every year, using renewable biological base materials to replace replacement Fossil raw materials. In addition, UPM has also obtained ECovadis Platinum certification, and has been selected as the UN global contract leader company, the Dow Jones Sustainable Development Index, and the S & P Global Sustainable Development Award. In more than 20 years deeply cultivated the Chinese market, UPM has also been committed to Yu continuously improves the efficiency of the energy use of the factory, and shares the value brought by the green innovation and sustainable development technology with the industry partners, and actively assumes the social responsibility of green development. "(Reporter Yang Xiufeng)

- END -

Qiqihar: Ecological Birds Singing

Right now is the season for the breeding of wild birds. As the ecological environm...

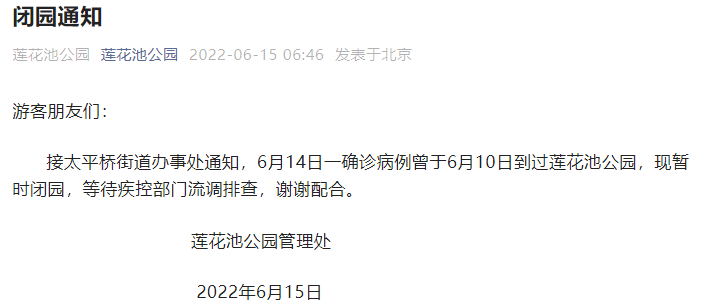

Beijing Lotus Pond Park: The confirmed case was visited, and the park is temporarily closed temporarily

Close Garden NoticeTourist friends:Plot of the Taipingqiao Street Office notified ...