Dagang Oilfield Green Technology System Realize the scale of production

Author:PetroChina Time:2022.09.14

Photo by Zhou Shuang

On September 11th, the reporter learned that through 5 years of practice, the Dagang Oilfield absorbs the industry experience and improves independently. And green and low -carbon development.

As of September 5, CCUS-EOR has implemented more than 320 wells at the scene, with an effective rate of 98.7%, achieved 193,000 tons of carbon utilization, 239,000 tons of oil, and precipitation of 1.692 million cubic meters. Consumption reduction.

Since 2018, Dagang Oilfield has led the "three integrations", focusing on the production and efficiency of the bottom water thick oil collection, the effective use of deep low -osmotic oil collection, and the benefits of shale oil collection. Experts and first-level engineers are CCUS-EOR project teams with the core and second and third-level engineers as the backbone of China. They have formed 13 key supporting technologies covering the theoretical model, process technology and practical methods. The development of benefits provides theoretical guidance to achieve leapfrog development of CCUS-EOR technology from scratch, scale from small to large. At the same time, the carbon source geographical information database within 250 kilometers around the Greater Port Oilfield was established, which provided carbon source information guarantee for the continuous development of the subsequent CCUS-EOR project.

Focus on the national "double carbon" goal, focus on the development status of thick oil bottom water and oil collection, combine the successful experience of high-efficiency production of thick oil oxide throughput, the company proposes to create the implementation of the implementation of the CCUS-EOR demonstration area of the characteristic thick oil in the large port. "In the context, the industrialization application of the Beijing -Tianjin -Hebei region and the development of low -carbonization transformation in the oil and gas industry laid a solid foundation. Carbon dioxide throughput has been implemented more than 300 wells at the scene, using carbon to 177,000 tons and 234,000 tons of oil.

In response to the development difficulties of deep infiltration oil collection "not to enter and unable to drive", in April 2021, the leaf 21 break block was the project support, and the Dagang Oilfield implemented the first deep low -osmotic carbon -driven carbon buried well well. Group test. In order to effectively control the potential gas channeling caused by fracture cracks, the plan design is implemented by carbon dioxide-water alternate drive. At present, the test has completed the injection of carbon dioxide in the first section of the first section of the plug, with a cumulative carbon injection of 11,500 tons. It is expected that carbon burial is 04,400 tons, which is in the stage of water injection section. During the experiment, the beneficiary oil well saw the better oil increase effect. The daily increased oil reached 5 tons, and the stage control was reduced by more than 2,300 tons. The test was initially successful, providing technical reference for the efficient development of similar oils at home and abroad.

At the same time, the Dagang Oilfield has further expanded the application of carbon dioxide production technology to shale oil collection, which effectively solves the problem of adding problems in shale oil. Up to now, this technology has been implemented with a total of 9 wells, 4,300 tons of carbon injection, and an oil increase of more than 3,000 tons at the stage. The value creation of value is increased with benefits, helping the shale oil production.

Reporter | Liu Ying

Correspondent | Wang Haifeng

- END -

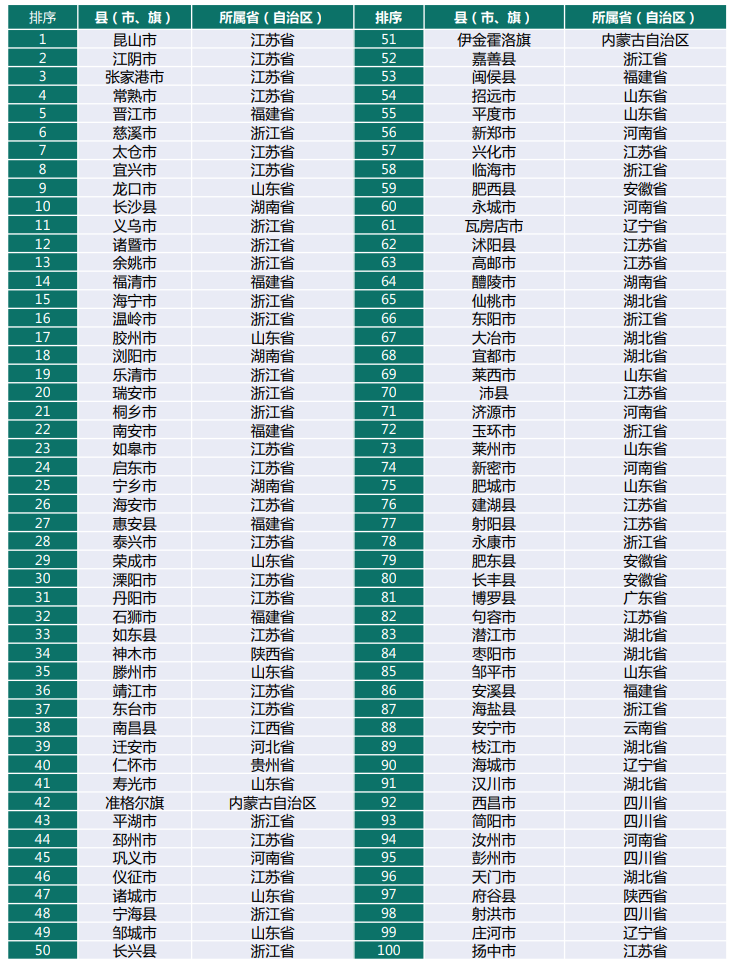

2022 Sidi Top 100 Prefecture released the list of 4 Sichuan places

Chuanguan News reporter Wang GuopingOn July 20, the Consultic Consultant County Ec...

The enrollment season | Gourmet strategy is in hand.——Gouris

NO.68 Food Guide THU's ■■■■■■■■■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■...