Treatment of sewage up to 380 million tons!More than 700 day and night protection of the Wuhan North Lake Sewage Treatment Plant

Author:China Net Hubei Time:2022.09.20

From the southwest to the northeast, the mighty Yangtze River nourishes Wuhan. In the south of the Yangtze River, north of Wudu Road, and the "channel" related to people's livelihood in Wuhan under the ground -starting point from the Erlang Temple Pre -processing Station. From west to east to the North Lake sewage treatment plant, it is treated from "turbidity" to the Yangtze River from "turbidity" to the Yangtze River in accordance with the way that is better than national standards.

On September 16th, the sewage deep tunnel with the largest transmission flow and the longest transportation distance has been officially opened for the 2nd anniversary. There is no doubt that the Beihu sewage treatment plant under Wuhan Holdings is a key node for the Dadong Lake Deep Tunnel. Since the trial operation on September 16, 2020, the plant has dealt with a total of 380 million tons of sewage, a total service area of about 130 square kilometers, and a total service population of about 2.4 million.

Factory area bird's eye view

How to ensure that this wide range of radiation scope and affecting major people's livelihood projects has been "obscured" and running smoothly for more than 700 days? Recently, the reporter came to the North Lake Sewage Treatment Plant to find out.

Smart Water Affairs Help High -efficiency Management

"Since the trial operation, we have achieved the 'zero accidents'." Li Bei, director of the operation management department of the Beihu Sewage Treatment Plant, said, and all this benefits from the "smart brain" of the factory.

On the third floor of the deep tunnel pump room, the central control room is the "brain" of the entire sewage treatment plant. There is an electronic screen of about 10 meters long and about 3 meters high in the central control room. Data, there are no views on the screen. "The factory area has been equipped with a smart operation system. Each corner is in its control. Just a little bit, you can monitor and dispatch any equipment and personnel information in the factory." Li Bei said.

Central control room

The smart operation system is the "proud work" of the Beihu sewage treatment plant. In appearance display, the staff carefully designed and produced the 3D three -dimensional modeling of the entire plant. In the case, the system can provide more automatic control, more comprehensive perception, more timely response and more scientific decisions for production monitoring, operation dispatch, daily patrol, etc., and improve the operation and maintenance efficiency and standardization of sewage treatment facilities. "People only use the key point of inspecting machines that cannot be found, which greatly improves our work efficiency."

Optimize innovation and achieve high -quality development

As the largest sewage treatment plant in China at one time, the North Lake Sewage Treatment Plant has deep water depth and large processing volume, which means huge power consumption. Among the direct production costs of sewage treatment, electrical energy consumption accounts for more than 30%. In order to respond to the "carbon neutral" goal and the "energy consumption dual control" policy, the factory optimizes the energy consumption and carbon emissions management of sewage treatment facilities, and builds a distributed photovoltaic power generation project.

PV

After accurate calculation and reasonable scheduling, in the case of ensuring normal and smooth operation, the Beihu sewage treatment plant closed the use of some facilities and equipment, such as turning the 24 water -producing corridors of the MBR processing unit into a cold state, and the supporting and sweeping scanning The fan only needs to be enabled, and it can be enabled at any time when emergency.

At the same time, the entire plant adopts a technical advanced microcomputer measurement and control management system. Various equipment can automatically adjust the number of operating tables or operating time according to parameters and other parameters of sewage water, which can not only improve internal management, but also enable the entire sewage treatment system Run the lowest running cost.

In terms of process technology, the factory technicians are still optimizing and improved, and have adopted innovative aeration control strategies. During the highest peak, the North Lake Sewage Treatment Plant can use about 250,000 yuan a day. After a series of improvement measures, the current power consumption of the plant is maintained within 230,000 degrees a day.

Pursue excellence to build a high -quality team

There are not many employees in the large factory area, but the staff in each post are busy and orderly, or they are inspecting inspection equipment facilities, or in maintenance and maintenance equipment, or in detail in each group of operations Data ... The smooth operation of the North Lake Sewage Treatment Plant is inseparable from the day and night guardianship of this group of staff. Frozen three feet is not a day cold, and it is not a day to train a well -trained team.

Deep tunnel pump room

The staff of the Beihu Sewage Treatment Plant summarized experience in actual operation, transformed into a simple and easy -to -understand operation step, and then brought it into a book. Maybe just how to switch the "small knowledge points" like the valve, the operating points will be listed on the manual, and detailed illustrations will be attached. After all the relevant personnel will sign, they will sign under the corresponding knowledge point.

The work team of the factory does not stop here. In July 2021, the Beihu Sewage Treatment Plant founded the Liu Haelong Technician Studio, and used the studio as a carrier to carry out skill training and technical reform work for the safety of the North Lake Factory. The quality of water quality lays a good foundation.

As the person in charge of the maintenance management department of Beihu Sewage Treatment Plant, Liu Hailong not only obtained the qualifications of the senior technician of the fitter, but also won the title of technical ability of Wuhan in 2021.While constantly improving his own technical level, he also taught his skills to other workers in need.Liu Hailong regularly carried out the training of safety production, skills and technical knowledge in the studio, explained the knowledge in a simple way, consciously combined with various problems encountered in the work, taught practical skills, and established a "mentor with apprentices" system.Gang Yi "," point -to -point "guidance, inheritance technology, and give full play to the role of technical studio's skills talent training.The city's water purification water shows the three town of the three town.With more than 700 days and nights, the North Lake Sewage Treatment Plant did not suspend its transportation for a day, and fully strive to protect people's livelihood, safety, and stability.Four water governance "contributes its own power.

(Correspondent: Hu Yi, Yu Zhihui)

- END -

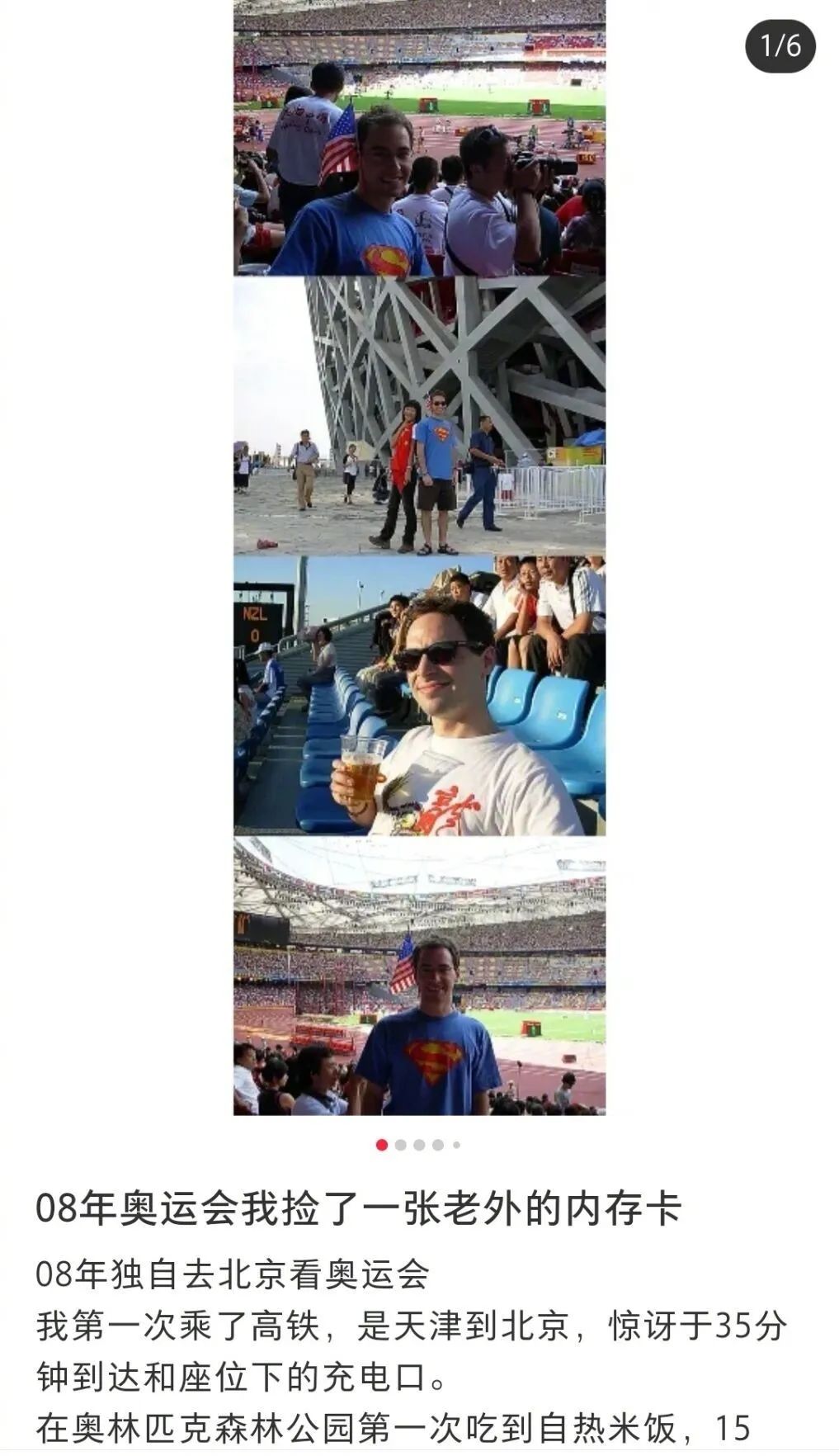

Rush on the hot search, look for this foreigner on the whole network

Pick up a foreigner memory card during the 08 Olympic Games: I want to find the ow...

Our province announced the number of basic pension insurance benefits for employees in 2022

Our province announced the number of basic pension insurance benefits for employee...