Progress | New excellent soft magnetic non-crystal-nano crystal transition alloy

Author:Institute of Physics of the Ch Time:2022.09.24

Iron -based amorphous alloys are one of the amorphous alloys that have been widely used at present. Due to its unique and disorderly structure, it shows extremely excellent soft magnetic properties, such as low -correction and low loss, and is widely used in magnetic devices of various types of electrons, which has significant energy -saving and environmental protection advantages. Suitable thermal treatment of such amorphous alloys can analyze small and uniform nanocrystals on the amorphous matrix, so as to obtain nanocrystalline soft magnetic alloys, which can further improve their performance. Modern electronics equipment is gradually developing towards miniaturization, high efficiency, and energy saving. This requires soft magnetic alloy materials to have high saturated magnetic induction strength (BS, which is conducive to miniaturization) and low orthodontics (HC, which is beneficial to low loss). However, compared with the commonly used silicon steel materials, although the amorphous/nanocrystalline alloy is small, the BS value is low (the current commercial materials are generally below 1.7 T). In the past few decades, in order to improve the BS value of soft magnetic non -crystal/nano -crystal alloys, researchers have made a lot of efforts. The design strategy of adding ferromagnetic element content to the alloy is the most effective and most widely used method. Some alloy systems such as FE- (BSIPC) and FE- (BSIPC) -cu with a small amount of metal elements and ultra-high-speed rail magnetic elements have also been developed. However, the increase in the content of iron magnetic element will lead to the rapid decline in its alloy amorphous formation capabilities, making it difficult to control the process of nanocrystalline nucleus, and it is difficult to obtain low HC during subsequent heat treatment. This leads to a mutually exclusive relationship between BS and HC of amorphous/nano -crystal alloys. How to obtain high BS and low HCs at the same time has become an important challenge in the current research of soft magnetic non -crystal alloys, which is also vital to its application in high -power density scenarios.

Recently, the Institute of Physics of the Chinese Academy of Sciences/Beijing Condensing Physics National Research Center and Songshan Lake Materials Laboratory jointly trained doctoral students Li Xuelong, post -doctoral Zhou Jing and others under the guidance of Associate Researcher Sun Baoan, Bai Haiyang researcher and Wang Weihua Design ideas have successfully developed a new type of soft magnetic alloy material between traditional amorphous alloys and nanocrystalline alloys, showing high BS (up to 1.94 t) and HC as low as 4.3 A/m. Breaking the mutually exclusive relationship between BS and HC in the iron -based amorphous nano -crystal alloy system.

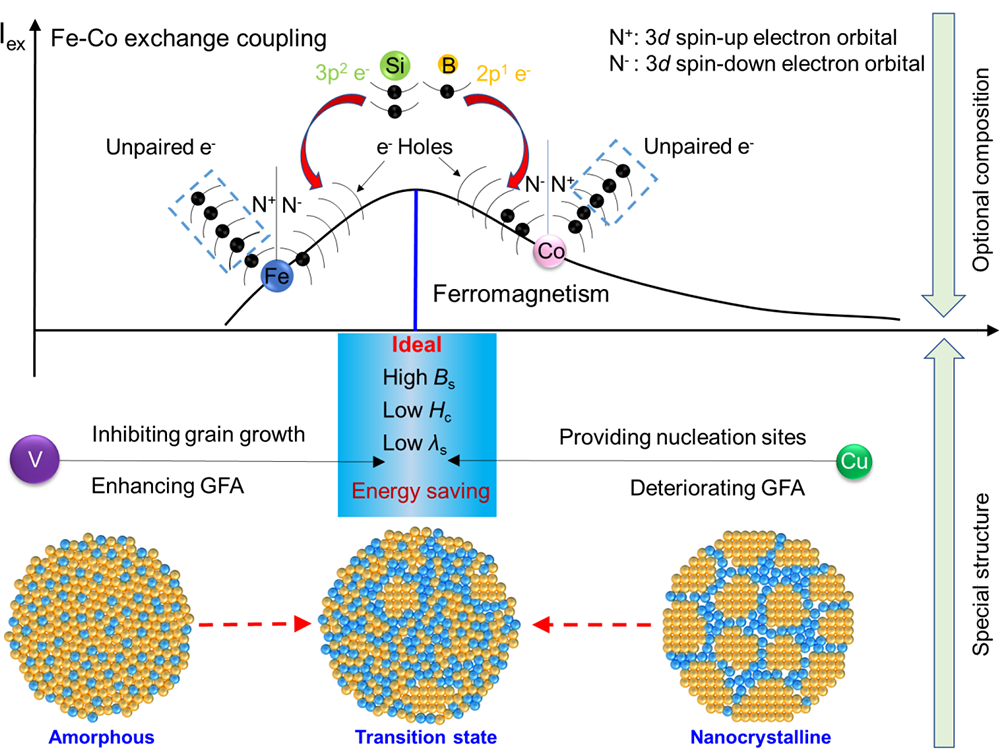

Figure 1 alloy design concept. Choose the proportion of ferromagnetic elements (for example, Fe, CO, etc.) to improve the coupling and maintain a higher amorphous formation ability. Crystal structure

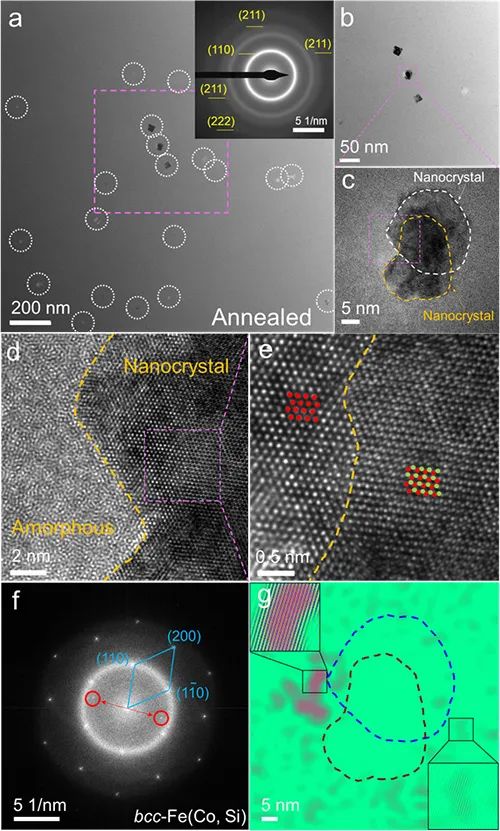

Different from the component design method that used to improve the content of iron magnetic elements in the past, here is the addition of an appropriate amount of CO elements to improve its exchange coupling, and the microcontroller CU, V and other elements are balanced The interrelationship between large (Figure 1), through an appropriate experimental verification, designed a alloy with the composition of (Fe0.8CO0.2) 85b12si2v0.5Cu0.5. Through the melting band method, the unique micro -structures of nested nano -crystals are scattered in amorphous substrates (Figure 2).

Figure 2 (FE0.8CO0.2) The micro structure of 85 transitional alloy is manifested as nested nano crystals and a class crystal area less than 5 nm in an amorphous matrix

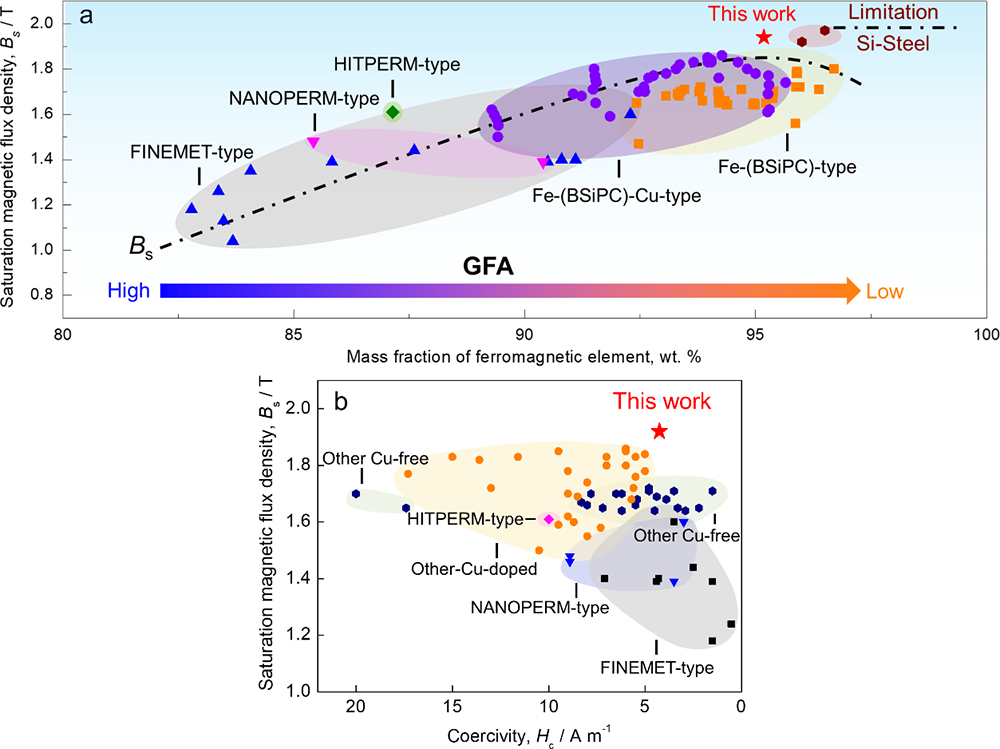

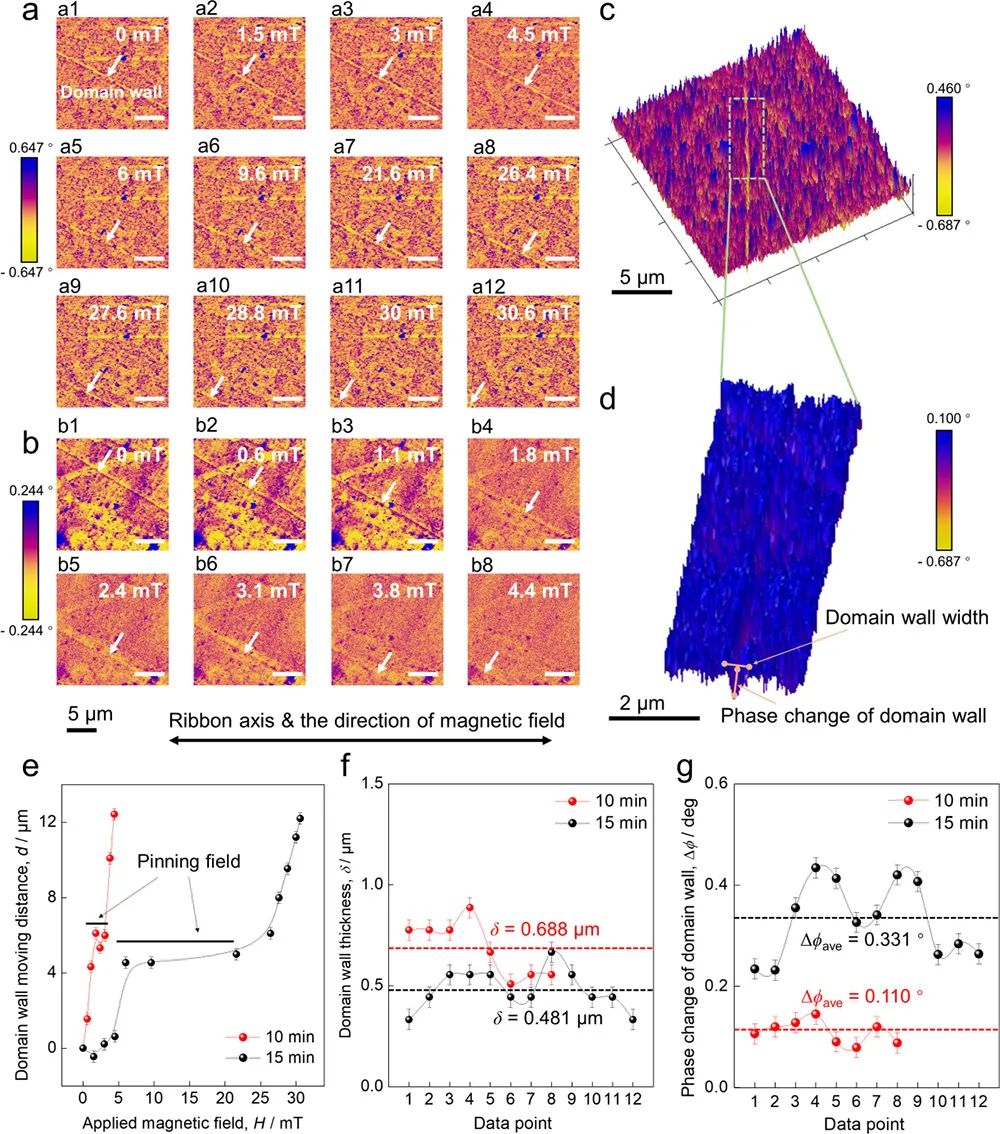

Compared with traditional nanocrystalline alloys, the size of the nanocrystalline volume in the alloy is only 0.5%, and at the same time, there is a type of crystal clusters with a size of less than 5 nm around the nano crystal. After magnetic performance testing, the amorphous-nanocrystal transition alloy has a BS of up to 1.94 t and HC as low as 4.3 A/m. The BS of this material is the highest value of nano -crystal alloy materials so far. At the same time, HC is also close to the minimum limit of nano -crystal alloy materials (~ 1 A/m). The mutual relationship between meters (Figure 3). Studies have found that the ultra -high BS value is the result of the interaction of local magnetic torque exchanges. This is the commonly added CO element and the nested nanocrystone (and the <5 NM -size class crystal structure) of the appropriately added small size distribution. Caused by action. In addition, the study also used magnetic microscope (MFM) to observe the structure and movement method of the de -to -depth wall under the action of external and plus magnetic fields. The low magnetic opposite sex caused by the structure.

Figure 3 Summary of the soft magnetic properties of typical ferromagnetic nano -crystal alloys

Figure 4 (FE0.8CO0.2) 85 transitional alloy band band of the magnetic domain structure measured by MFM and its evolutionary behavior under different magnetic fields

Based on the design concept of this new amorphous-nano-crystal transition alloy, it is expected to develop more non-crystal-based materials with excellent comprehensive soft magnetic properties. In modern electronic products, it provides a new paradigm for exploring the preparation of a new generation of high -performance soft magnetic materials.相关研究成果以“Exceptionally High Saturation Magnetic Flux Density and Ultra-low Coercivity Via an Amorphous-nanocrystalline Transitional Microstructure in a FeCo-based Alloy”为题,于2022年8月29日在线发表在Advanced Materials上。 Li Xuelong, Dr. Zhou Jing as the first author of the dissertation, associate researcher Sun Baoan and the co -communication authors of the paper as the paper. The above -mentioned research work has been strongly supported by the National Key R & D Plan (2018YFA070703603) and the National Natural Science Foundation of China (52192601, 52192602, 52101191, 11790291, 61888102), and the major support of Basic and Application Basic Research Research (2019B030302010, 2020B1515120092). Article link: https://doi.org/10.1002/adma.202205863

Edit: Shepherd

- END -

Grasp the "main position" and keep the masses "money bags"

Grasp the main position and keep the masses money bags——In Agricultural Issuing ...

Shanxi Province undertakes the Pearl River Delta Industry Transfer Cooperation and Linking Meeting in Guangzhou

Shanxi Daily reporter Yan Jie and Sun Rongxiang reported that on July 13, Shanxi P...