State Grid Yunyun Pan Power Station Pressure Steel Pipe Installation Project is officially launched

Author:Report Time:2022.09.24

Recently, the State Grid Xinyuan Zhejiang Yunyun Pumping Energy Power Station was completed in the first quarter, marking the official launch of the Pingyun Power Station pressure steel pipe installation project.

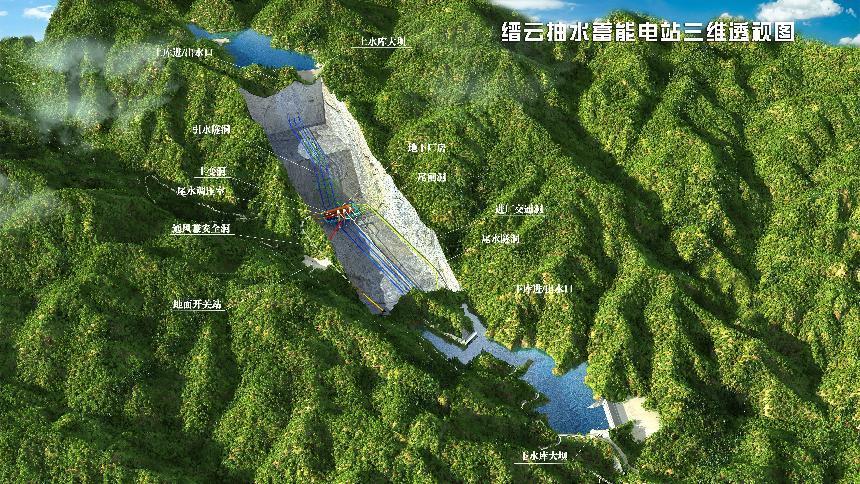

Zhejiang Yiyun Pumping Power Power Power Station is a key construction project in Zhejiang Province. It is located in Dayang Town and Fangxi Township, Daiyun County. The installed capacity of the power station is 1.8 million kilowatts. Important measures. After the project is completed, the system can save about 230,000 tons of coal consumption each year, reduce carbon dioxide emissions by 460,000 tons, and undertake tasks such as peak regulation, frequency regulation, phase adjustment and emergency accidents. Southern Zhejiang special high pressure is of great significance.

The total length of the water transmission system of the Yunyun Power Station is 3830 meters, and the pressure steel pipe is equipped with 1,349 sections, of which the maximum steel pipe has a diameter of 6 meters and the total number of projects is 18,860 tons. The stress steel pipe in this lifting is 2 meters in diameter and weighs 7.282 tons. It is located at No. 3 water diversion system and connects the leap valve extension section of the unit 6 to transmit the power water body for the unit.

Pressure steel pipes are important pipelines that connect the inlet and outlets and water pump water turbines. It is an important task of transmitting water to the water turbine to the water pump, and has high requirements for its manufacturing quality. In order to complete the pressure of stress steel pipes at high quality, the Yiyun Power Station adapted to local conditions and worked together by the participating parties to build a pressure steel pipe plant with high degree of equipment automation, high assembly operation efficiency, advanced overall manufacturing process, and representing domestic first -class levels.

At the same time, in order to improve the mechanization and intelligent and intelligent level of stress steel pipe manufacturing, the State Grid Xinyuan Zhejiang Zheyun Pumping Storage Co., Ltd. comprehensively optimized the layout of the plant area, scientific planning production station, a large number of automated equipment, and self -developed design auxiliary workers, and the introduction of dual introduction The construction of the dual -cutting gun of the station, the welding equipment of the longitudinal ring seams, and the bending machine of the hydraulic arc formula, etc., the first velocity of the automatic circular automatic welding equipment has greatly improved the construction efficiency and safety level.

In addition, Yiyun Company jointly established the "Pressure Steel Pipe Manufacturing Installation and Management Party Member Youth Pioneer Team" to promote the leading party building to the front line of the project. High -quality manufacturing of pressure steel pipes. Actively carry out the five technical competition activities of the "Fourteen Five -Year Plan" theme of the "Fortune Fortune of Fighting New Journal of Fortune", and carry out welding standard technical technical competitions during the production of pressure steel pipes to promote the quality of the competition. The role of human "people" further improves the level of steel pipe manufacturing.

Up to now, the Plane Pipe Steel Pipe Factory of the Yunyun Power Station has produced 117 stress steel pipes, of which 4 of the water tube steel pipes have been produced, and the acceptance rate of acceptance is 100%, and the excellent rate has reached 100%.

After an hour of hard work, the first quarter of the pressure steel pipe was successfully lifted to the established location by the lifting equipment, and the completion of the node unveiled the prelude to the installation of the pressure steel pipe of the Yiyun Power Station, further promoting the progress of the water diversion system project, and realized the first stage to achieve the first stage at an early date. The crew of the crew laid a solid foundation.

Author: Correspondent Tang Xiao Wang Jiamin

Edit: Zhao Zhengnan

Editor in charge: Fan Bing

- END -

"Little Apricot" Cup The 2nd Children's Story of Chinese Medicine Story Contest officially launched

Dahe Health News reporter Cao CongOn August 1st, the Little Apricot Flower Cup wit...

65+279 are added in the local area, of which 11+71 is in Anhui

The National Health and Health Commission reported on the 10th that from 0 to 24:00 on the 9th, 31 provinces (autonomous regions, municipalities) and Xinjiang Production and Construction Corps reporte