Economic Perspective | Full firepower!Bingcheng opens the road of "green rise"

Author:Heilongjiang Daily Time:2022.07.12

Green cycle special reward 2 million! This is second to none in the country.

On July 2nd, the Harbin Industry and Information Bureau issued a public announcement planned to reward the 4 categories of 36 households in 2021. Among them, it is intended to reward 2 million national -level green manufacturing enterprises; 26 provincial -level green manufacturing enterprises reward 500,000 to 1 million; two national energy -efficient star companies reward 1 million each; 3 provincial -level water -saving benchmarking enterprises Each reward is 500,000.

A total of 36 million companies reward 36 million yuan! It can be seen that Harbin City has vigorously promoted the development of green and low -carbon, and promoted the determination of corporate circular production and industrial circulating combination. "Heilongjiang Province's" Fourteenth Five -Year Plan "Industrial Energy Conservation and Green Development Plan" proposes that it is necessary to accelerate the promotion of energy -saving carbon reduction and green transformation in our province, with the theme of promoting high -quality development, and deepening the supply -side structural reform. Dafeng carbon neutrality is oriented, comprehensively build a green manufacturing system, and promote industrial green low -carbon transformation to a new level.

So, what kind of company is a green manufacturing company, and how do they take the road of green development? Please see the reporter's investigation.

Autonomous innovation model!

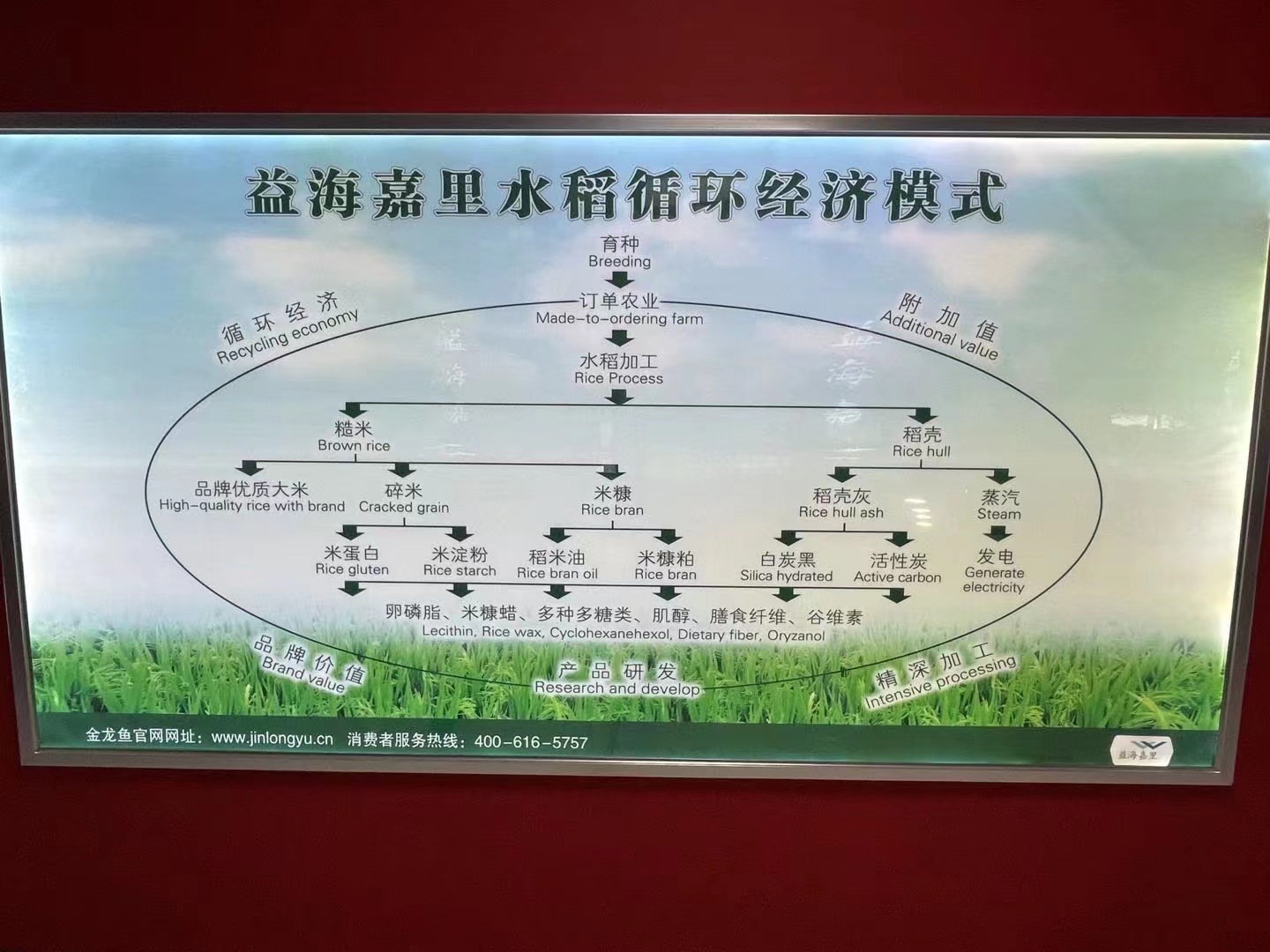

Yijieli: The rice circulation industry creates green benefits

Are you unfamiliar with Yijiali? Then you must know its long -standing brand Golden Morfana!

Entering the Harbin factory area in the Harbin factory in the Bingfang District (hereinafter referred to as "Yijiajiali") in the Harbin Food Food Industry Co., Ltd. (hereinafter referred to as "Harbin). After the rice shells on the outside of the rice are stripped out, they enter the rice shell warehouse. The second layer of rice bran is stripped out and entered the rice bran oil workshop. The processed rice bran oil is transported to the refined workshop. ... "Hu Xiaoying, personnel administrative manager of Yili Harbin factory, said.

The reporter saw that the rice grains were full and the color was crystalized through the visual window of the machine. Several workers shuttled the operation in the middle of major machines. Zhang Zhuokun, the director of the rice factory, said that the two workshops can produce 800 tons of finished rice per day. But do you know? The output value of rice accounts for only 80%of the annual sales of the rice factory.

What about the remaining 20%? "From rice circular economy deep processing products!" Zhang Zhuokun said.

Rice

Gen Rough Separation

Brown rice fine crushing

Rice shelling

For example, the rice bran of the by -product has become a high -nutritional rice oil. The rice bran meal after oil can be used as a feed. At the same time, the rice oil is rich in portized and pilotin. Raw materials.

Demonstration of Yili Kerry Rice Circular Economic Model

As an important part of the rice circulating economy, fatty acids, rice bran wax, rice bran fat, vitamin, and sulutic acid extracted from the rice oil by -products and rice bran meal are widely used in industries such as special oils, fat chemicals, and cosmetics. Among them, fatty acids are one of the main ingredients of soap, washing powder and other daily chemical products; rice bran wax can be widely used in leather care wax, floor wax, and car wax; rice bran lipids are stable, which is very suitable for fried cooking; It is the essential nutritional element of the human body. It is widely used in pharmaceutical products and cosmetics ... This series of products development enables valuable rice bran resources to fully develop and utilize.

"From the perspective of the sales situation this year, the output value of this deep processing is increasing year by year," said Wang Liqun, deputy general manager of the Harbin plant.

White charcoal black workshop filter machine

Taking traditional processing rice waste rice shells as an example, it can be used for combustion power generation after being stripped, so that the factory thermal power supply is fully self -sufficient. Not only can save energy, but also reduce the emissions of polluting gas such as sulfur dioxide, which not only solves the yellow pollution problem of rice shells, but also creates huge economic and social benefits. In addition, the rice shells are burned into ash and can also refine high decentralized white carbon black and natural filter activated carbon. This kind of rice shell white charcoal black is a pure natural renewable resource, which is more enhanced than ordinary white carbon black. It can increase the strength of rubber, reduce tire rolling resistance, and increase the fuel economy of vehicles. It is the best raw material for the production of green tires. It has become the development direction of the tire industry. It is promoting and applied globally, and market demand has continued to rise.

White charcoal black workshop reaction can

According to the "Sustainable Development Report of 2021", the "2021 Sustainable Development Report" shows that as of the end of 2021, it consumed a total of about 351,296 tons of rice shells, which means that through the efficient use of rice shells, it has reduced greenhouse gas emissions 412,266 Ton CO₂. Among them, in 2021, Heilongjiang produced 200,000 tons of rice shells, and the reduction of carbon emissions was evident.

"The rice processing base located in Jiamusi and the research and development headquarters of Shanghai has given the biggest technical support for the continuous innovation of 'deep processing and waste into treasures'," Wang Liquan said. "Wang Liqun said.

At present, the world's leading Yili Kerry rice circular economic model has been included in the national green development plan, and has become a strong proof of comprehensive improvement in China's manufacturing industry.

Change first!

Jiren Pharmaceutical: The transformation of the green manufacturing brought by the medicine machine

"We saw this new equipment that we saw in domestic drug opportunities. I just started buying one. It felt very good for a year, and I bought a few more." Speaking of the road to transformation of green manufacturing, Jiren, Heilongjiang Province, Jiren Jin Xin, chairman of Pharmaceutical Co., Ltd. (hereinafter referred to as "Jiren Pharmaceutical"), talked.

The reporter walked into the new Chinese herbal medicine processing workshop before entering the new Chinese herbal medicine. One or two new devices were placed in each room. "This is our new front processing workshop, which uses about 1500m2. , And realized digital intelligence control. The annual processing of medicinal materials has been increased from 1000T/year to 3000T/year. The overall function and efficiency have been improved. "Jin Xin said. Watching her introduce her baby like a few treasures, listening to her professional and vividly talked about the working principle of the medicine machine, as well as the sufferings they experienced in the transformation of the green manufacturing, the reporter praised the green leading change of this Longjiang Chinese medicine manufacturing enterprise. Power. High -efficiency cutting machine and drum screening machine linkage line

Traditional Chinese medicine companies, the treatment of the front -end medicinal materials must go through the "water washing, cutting, drying" process, and it takes a lot of water, electricity and gas, and the material is not dense in the non -dense state of the material. relatively low. The improved pre -processing process uses the clean -selection system of high -efficiency interceptor and drum screening machine linkage, plus the production method of dust removal facilities supporting the linkage line: water saving, solar terms (drying), time -saving and green environmental protection.

CNC boiled pot

For example, the dry cleaning equipment in the front processing link -drum screening machine is cleaned without water. Through wind selection and filtering to eliminate impurities, dust, screening the standard rate and drug loss are the same as manual operation, and save 4 labor force; from time to time; from time From the perspective, the straw stems and leaves were washed, drained, and dried to dry. It took at least 12 to 20 hours. After using this new drug machine, the entire process could be completed in four or five hours, which greatly improved the efficiency.

Jinxin introduced to reporters to the working principle of duplex high -efficiency drug cutting machine

Cure machine

"Adopting a clean -selected pre -system processing method can save about 50%of the power capacity than traditional cleaning and cutting dry. The company treats about 3,000 tons of medicinal materials a year, which can save about 9,000 tons of water." Gao Peng, director of the workshop Coal -fired heating generates steam, which not only pollutes the environment and increases costs. Under the government's advocacy, they switched to natural gas, and the equipment they purchased was also in line with energy conservation and efficiency of high -efficiency drugs, and the efficiency was several times. "Two equipment spent 1 million, which can currently meet the production capacity of our factory." Gao Peng said.

Another example is the problem of concentration of traditional Chinese medicine products. After large -scale production of traditional Chinese medicine, it is necessary to continuously heat and evaporate water until it is condensed into a thick paste state. For traditional Chinese medicine products that need dual -effect concentration, for the first time heating and concentration, they will put the remaining heat in the dual -effect concentrator for secondary heating, which greatly reduces carbon emissions, improves efficiency, energy consumption and single -effect concentrated device Compared to 50%compared to 50%.

Sunshine House Affairs Center

In addition to the production workshop, the factory introduced the concept of "low -carbon environmental protection, energy conservation and emission reduction" in supporting facilities. Zhu Jing, manager of the project department, said, "The construction of the experimental technology center uses a full glass interval to make full use of natural light.

"Do you invest so much, aren't you afraid that the cost is too high and slow?" Jin Xin said with a smile, industrial energy -saving and green development is a problem that every enterprise must face, and it is also the country and the province's requirements for the green development of enterprises in the province. " It ’s also a change of late and late. Why not act early! Now, this road of green manufacturing development is both provincial and time -saving, saving manpower, and reduced the cost of production of enterprises.

Green manufacturing opens the door to high -quality development of Harbin City

How to use the reward plan? Both companies have stated that in terms of social benefits or economic benefits, green manufacturing has opened another door to high -quality development for enterprises. They will continue to invest this part of the bonus into the development of green manufacturing and help enterprises the road to green development. Essence

"We re -prize is to encourage enterprises to take the road of green development, help enterprises green and low -carbon transformation, build new kinetic energy of green growth in Harbin City, and promote the high -quality development of the city in the city." As of now, Harbin has cultivated 26 national green factories, two green supply chain management enterprises, and two green design products. Cultivate 24 provincial green factories, 2 households in green supply chain management enterprises, and one green industrial park.

Source: Lottery News

- END -

Sunshine Assistance | "Facing the sun, blooming smiley faces" 2022 Huaxi Sunshine Aid Activities Warm Starter

Cover reporter Liu HaoyangThey are optimistic, positive, hard -working, and self -...

Easy to win 18 points!Shanghai Titan punch card in three quarters, and scored 27 points for confirmation!

Today, the men's basketball team in 2022 officially started.Click (up to 30 words)...