Cover the house on the moon, the academician team of Huazhong University of Science and Technology studied the robot to make the moon -faced moon -faced base

Author:Changjiang Daily Time:2022.07.14

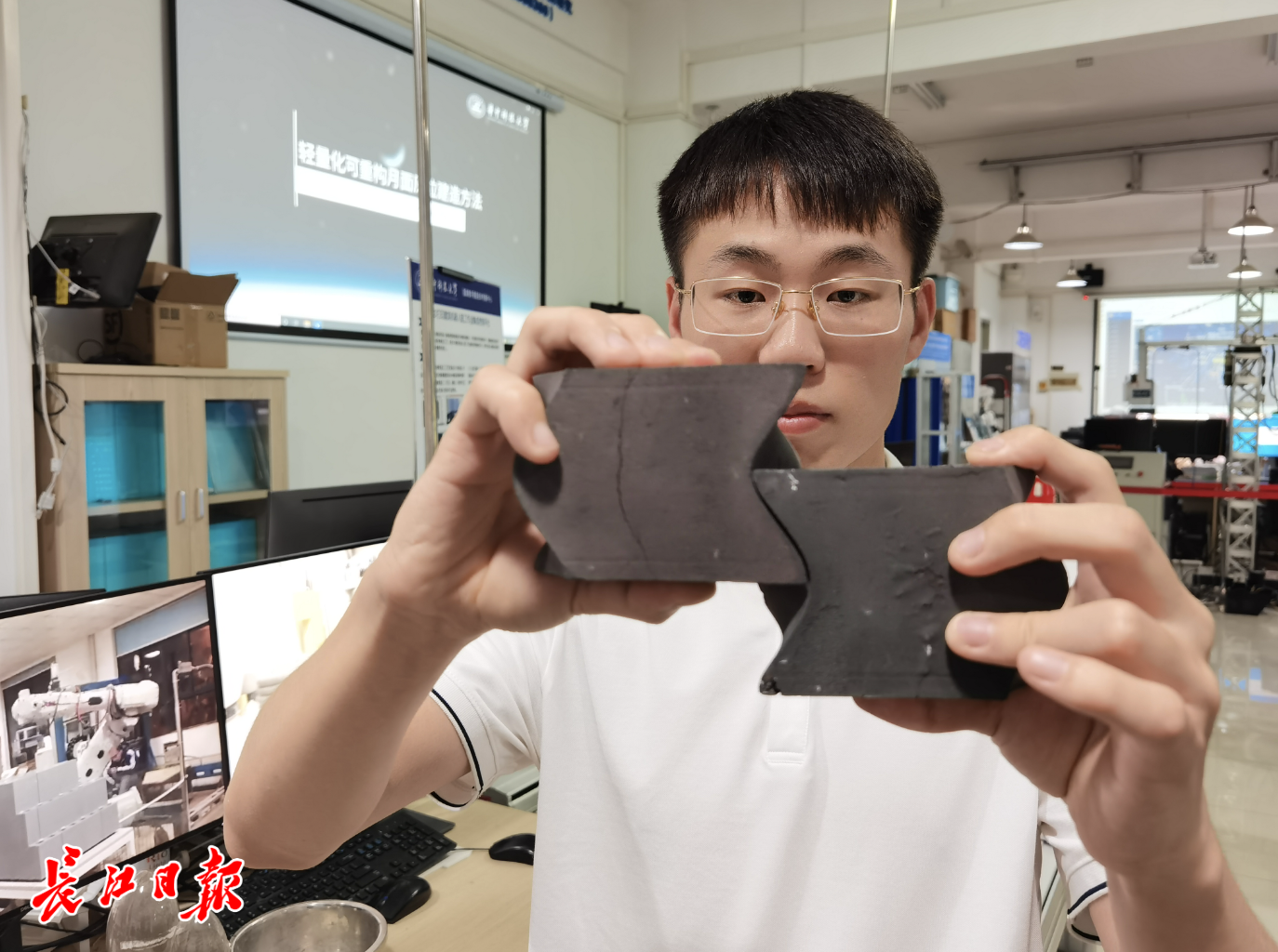

Professor Zhou Cheng checked the "Month Board" printed by 3D. Reporter Yang Jiafeng Photo

Do you dare to think about it on the moon? Academician Ding Lieyun's team of Huazhong University of Science and Technology not only dares to think about it. They named the moon -faced base style built on the moon as "Moon Bo Zun", which is a building that looks like an eggshell. It is planned to burn the moon brick with a moon soil, and then build it with robots.

They have prepared the first domestic simulated monthly vacuum sintering printed sample to achieve a major breakthrough from "from 0 to 1". Ding Lieyun introduced that "Monthly Pot" was built on the moon before the moon or then on the moon, and has not considered maturity. The pre -research is a kind of exploration.

Moon base building setting "Moon Bo Zun"

Like a vertical egg shell

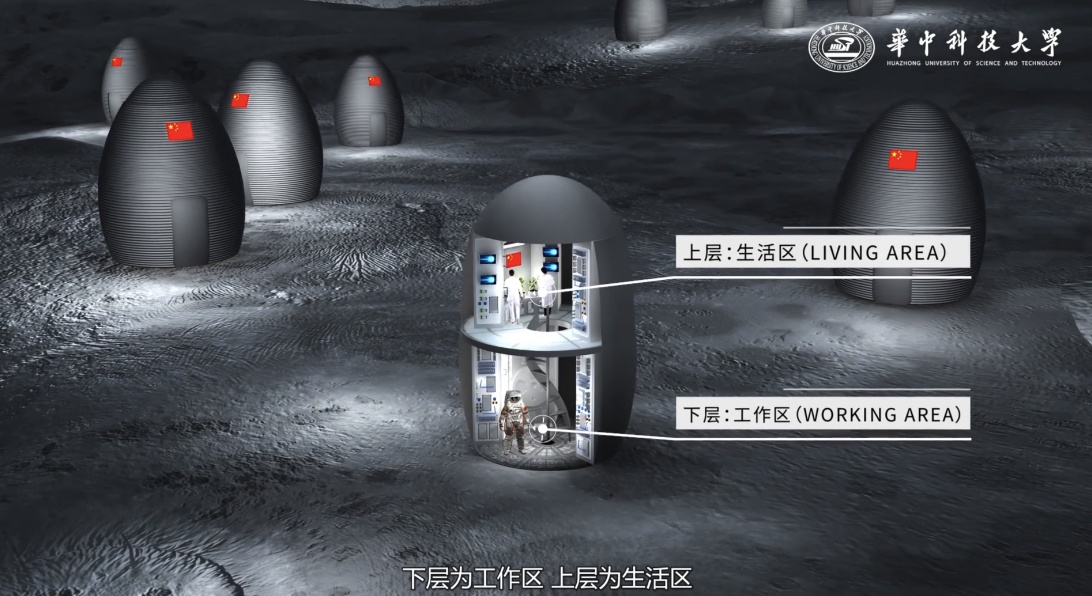

The "Monthly Pot" Moon Base renderings, the "moon spider" on the left is to build a moon pot Zun. (Photo Conferry at the National Digital Construction Technology Innovation Center)

On July 7, at the National Digital Construction Technology Innovation Center of Huazhong University of Science and Technology, the reporter from the Yangtze River Daily saw the 3D printing model "Moon Board". From the outside, it looks like an enlarged egg shell standing on the ground.

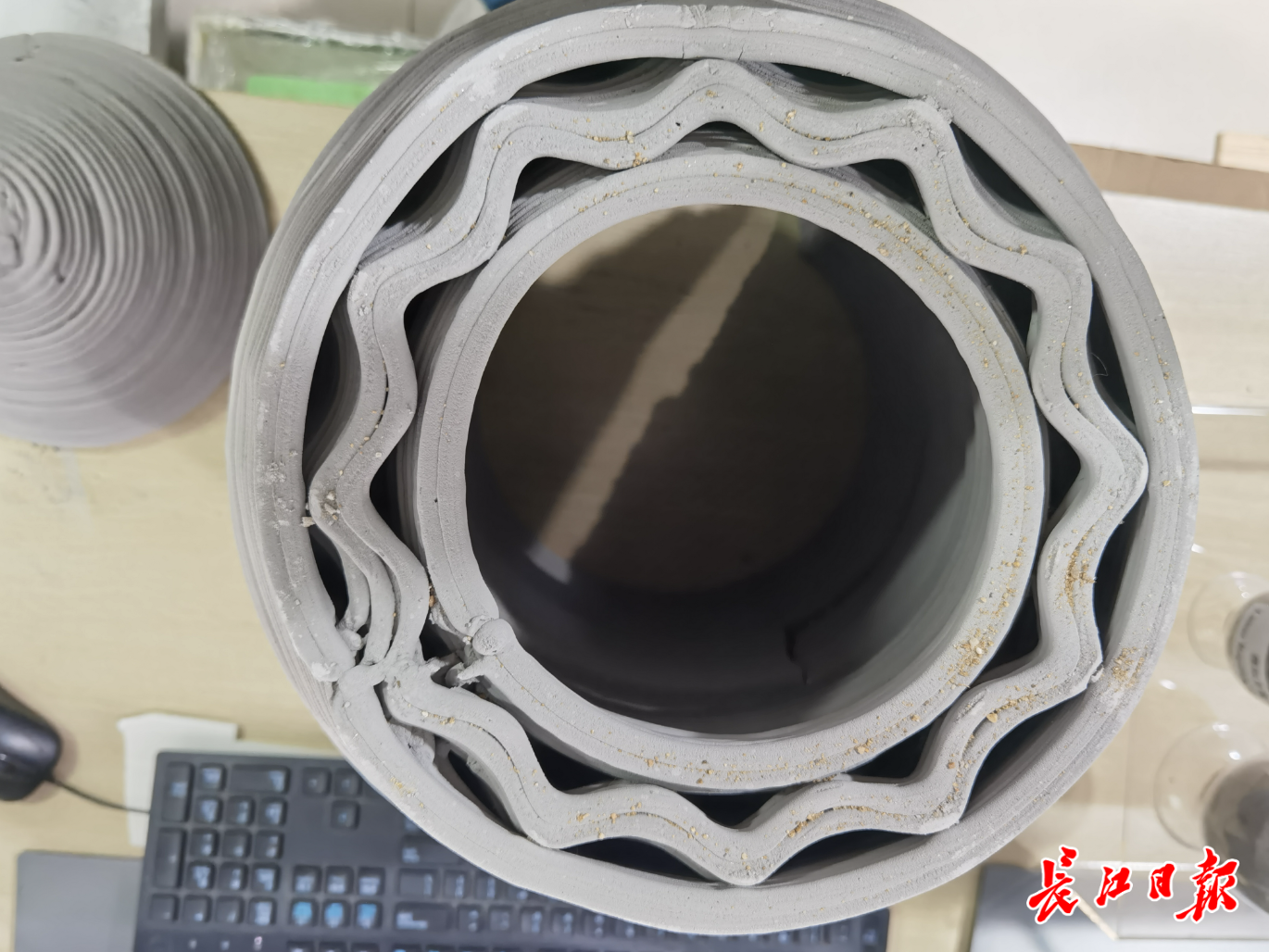

As a building, there is no load -bearing "four beams and eight pillars" in the "Monthly Pot". At the top of the egg shell is the dome structure. The eggshell body is divided into two layers in the inner and outer and outer layers. A layer similar to the ribs in the middle to enhance stability.

"Monthly Board Zun" internal structural schematic diagram. (Photo Conferry at the National Digital Construction Technology Innovation Center)

Professor Zhou Cheng, director of the Department of Digital Construction and Engineering Management, School of Civil Engineering and Water Conservancy Engineering of Huazhong University of Science and Technology, introduced that the "Moon Board Respect" in front of the reporter is a narrow version. Its real length and width are 3 meters, similar to a round -structured house The room is divided into two floors, divided into work rooms and rest rooms.

This bold idea was proposed by Ding Lieyun, an academician of the Chinese Academy of Engineering and chief scientist at the National Digital Construction Technology Innovation Center. They combine the construction method of traditional Chinese brick masonry with the 3D printing and construction method, and use the overall prefabricated assembly and local printing connection to design and build a moon base.

"Moon bases cannot be built from the earth with building materials. In this case, the cost of building will be extremely expensive." Ding Lieyun positioned the "moon pot" as "built in situ", that is, the main construction materials are derived from the moon itself rather than the earth itself, not the earth itself "It started to feel difficult, now there are some technical support, not as difficult as the original."

Because there is no atmosphere on the moon, and the heat capacity and thermal conductivity of the moon surface material is very low, the temperature difference between day and night on the surface of the moon is very large. During the day, the temperature of the moon on the surface of the moon can be up to 127 ° C in the place where the sun is vertical; at night, its surface temperature can be reduced to minus 183 ° C. Building a house in such a place is undoubtedly a test.

"The architectural style should be fully considered." Zhou Cheng said that what kind of building built on the moon, they have been trying all kinds of attempts. The team initially tried the dome structure, arched structure, and cylindrical structure. Many shapes were repeatedly tried to meet the environment of the moon surface and facilitated construction.

At the end of 2021, the "moon pot residence" of the erected eggshell became the styling style of the moon base building. "This is in line with Academician Ding Lieyun's request to reflect both Chinese elements and a sense of technology." Now, Zhou Cheng's daily research work is dealing with this "egg shell", what materials, what tools, and how to build.

The son of elementary school was very excited after learning that Zhou Cheng studied the use of the "Month Hun". After returning home from school every day, he tangled his father and kept asking. In the eyes of children, Chang'e running the moon, Wu Gangju, and Tengu swallowing the moon are all legends. What else is more dreamy than doing a house on the moon!

Zhou Cheng said that the moon surface earthquake is frequent, and the stability of the shape of the "Month" can resist the small earthquake, which also meets the efficiency of the building thermal insulation. China's lunar exploration project shows that the moon's Antarctic may have continuous light areas, which can be used as an ideal location for the moon base.

Brick with a tenon -and -mortise structure with monthly soil

Robot assembly and construction

Han Wenbin showed the moon soil bricks they printed with tenon -and -mortise structures. Reporter Yang Jiafeng Photo

The international consensus on the construction of the moon is that they do not bring material from the earth, and use the materials on the moon as much as possible for construction. The volcanic ash found by the Ding Lieyun team had previously found at a crater at Jilin, becoming a simulated moon soil for the construction of a "moon pot."

During this summer vacation, the National Digital Construction Technology Innovation Center is also hot. Two doctoral students in the room, Han Wenbin and Wang Yu to the electric heating furnace to watch the process of simulated moon soil sintering tiles, and see that sintering products are not reliable in the moon environment.

After the completion of sintering, Han Wenbin studied the strength, thermal performance, durability, etc. of the product, and Wang Yuxiang focused on further optimization of the 3D printing process under the arrangement of Professor Zhou Cheng.

"The biggest challenge of the moon building is the extreme environment." Zhou Cheng listed the five major challenges of the moon watch environment to the construction of the "moon pot residence". In addition to the huge temperature difference between day and night on the structural performance of the house, there are also "moon shocks" with a vacuum environment, longer and frequent frequency, frequent impact on the moon surface, and moon surface gravity that are different from the earth's vacuum environment, longer and frequent frequency. Disadvantages such as the stress state of the structure.

The team initially imagined that two ways were used to build a "moon pot respect" in the moon watch. One uses 3D printing construction, first use the grouting reinforcement method of the monthly table to make the foundation, and then print the structure on the foundation. The robotic arm assembly and construction, the solar tiles with solar or laser sintering are stitched through the robotic arm, and the "Monthly Pot" dome in advance. The two construction methods have their own advantages. 3D printing needs to bring adhesives to the moon from the earth. The weight of the general adhesive accounts for 10%to 15%of the entire building material. "If the" Moon Bo Zun "; there are 20 tons, then 3D printing requires at least 2 tons of adhesive." Han Wenbin said that 2 tons of adhesive plus 300 kg 3D printing equipment, a total of 2.3 tons of materials are sent to the moon, The total cost is 15.4 billion yuan, and the cost per square meter building costs 850 million yuan, which is much higher than the cost of ground building.

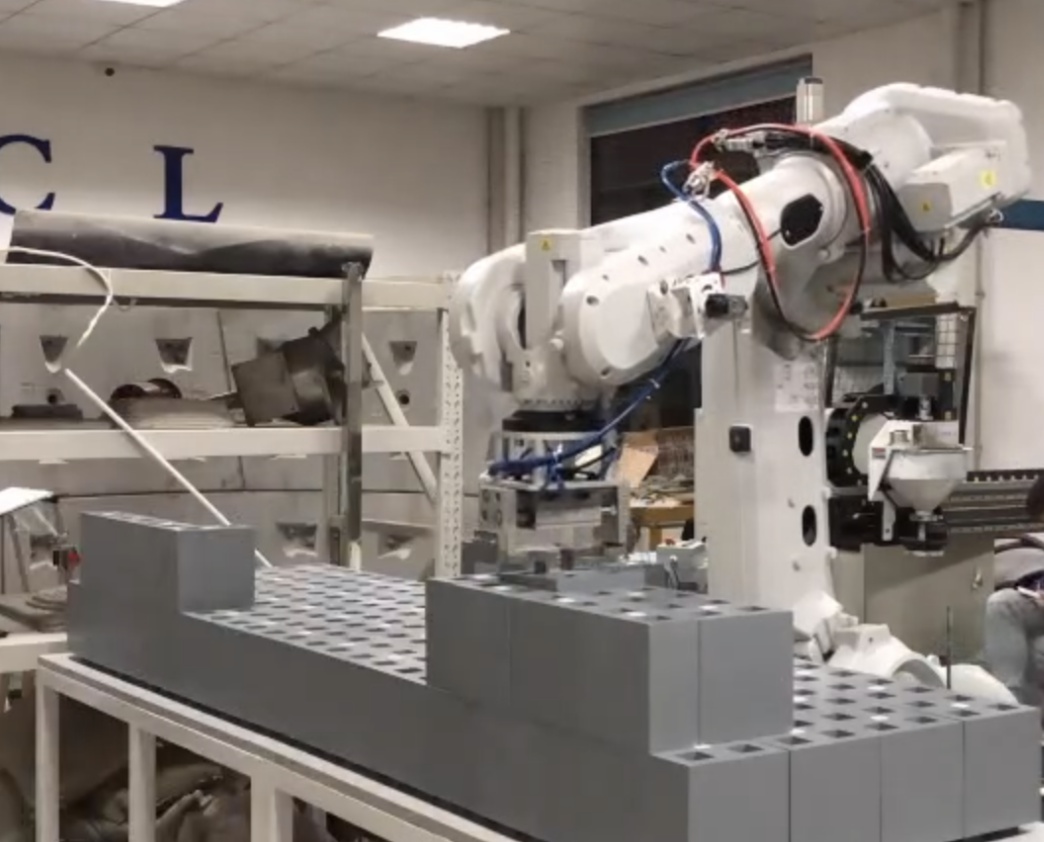

Use a robotic arm test to complete the assembly of the monthly soil brick. National Digital Construction Technology Innovation Center Photo Confer

The robotic arm assembly construction requires a high -energy beam (solar or laser) to burn the monthly soil, and spread a layer of moon soil sintering once. So until the "Month Board Zun" is all assembled and formed. The advantage is that the construction cost is relatively cheap. It only requires robotic arm and firing equipment, which is lighter than 3D printing to the moon, and the construction cost is reduced. However, this kind of construction risk is high, it is difficult to overcome the influence of the temperature difference between the moon table, and it is easy to cause structural deformation.

Zhou Cheng introduced that the technical system for the construction of the moon base abroad is 3D printing. This process can build a variety of shapes of moon base structures, but 3D printing is a continuous process. Once the printing process is broken and cracking, the entire structure will fail. The risk of one -time molding is very high, and at the same time, it consumes too much energy.

Their team draws on the traditional Chinese masonry and tenon -and -mortise connection methods, and proposes to use the moon soil to produce a moon soil brick with a tenon -and -mortise structure, and then assemble and build it. Masonry, at the same time, use 3D printing to strengthen the connection to complete the structure to avoid structural deformation.

Ding Lieyun's team finally incorporated two construction plans into a robot called "Moon Spider". Zhou Cheng said that the "Moon Spider" belongs to the 3D printing robot. Looking like a spider from a distance, the upper part is a mixed mechanical arm, and the lower part is a multi -footed platform. According to the design requirements, the robotic arm has 200 kg, the chassis is 500 kg, and the robotic arm can also be replaced with a 3D printer during construction. The steps of "Monthly Month" and the moon printing are the same. The difference is that the construction environment is different. The construction of the moon surface needs to consider the structure and the material.

Wang Yu also revealed to reporters the idea of reducing costs. He said whether the 10%to 15%adhesive can be reduced to less than 10%, and the intensity is still unchanged; robotic arm assembly construction can design a more lighter device to reduce the monthly transportation cost.

The construction of the moon's own materials will greatly reduce costs, and it is also the path abroad. Zhou Cheng said, "Building a house on the moon is not necessarily a matter of our generation, but in the future, someone will solve this problem. The research on the construction of the moon base can also give birth to new technologies and formats, such as 3D printing and construction. , Robot masonry, etc. "

I did not stay on the paper

Lead the team to say that you can do it

"Monthly" has a mezzanine structure. Reporter Yang Jiafeng Photo

The idea of building a moon -faced base began in 2015. At that time, Academician Ding Lieyun, who focused on digital construction research, found that "the most important aspect of building transformation and upgrading is 3D printing, and the idea of the moon printing base is a very natural idea." Some architectural landscapes or small structures It is often not possible to do artificially, and it is easy to complete the use of 3D printing, which makes Academician Ding Lieyun be keenly aware that unmanned 3D printing can only be valuable in extreme environments. Where is the extreme environment? The first thing he thought of was the extreme environmental environment, such as on the moon or Mars. He said, "This is a natural idea, not a sudden imagination."

Academician Ding Lieyun did not stay on the paper, and aimed at the moon base construction leading team to say that he would do it. "At that time, we studied ourselves and invested ourselves." Zhou Cheng recalled to reporters. After they started the research of this project, Academician Ding Lieyun led them to the relevant ministries and commissions, and the other party was "surprised."

Wu Weiren, chief designer of China ’s lunar exploration engineering and academician of the Chinese Academy of Engineering, paid attention to this scientific research project and believes that the idea of the moon printing base-“ Lightweight Reconstruction of the Moon Construction Method Research ”is a basic research and is very valuable.

At the end of 2021, the Ministry of Science and Technology included the "Lightweight Reconstruction Moon Construction Method Study" into key research and development plans, becoming a key project for "engineering science and integrated cross". Huazhong University of Science and Technology became the chief scientist unit of the project.

"The construction of the moon base base is a long -term goal. At present, according to the target of the subject, we have the confidence to achieve it." Ding Lieyun told reporters that there are still a series of problems to solve the current project projects. "In the future, how to work on the inflatable facilities and the specific location of the moon surface selection of the" moon pot ", many issues need to be solved.

"What we have done at present is the exploration from 0 to 1. It cannot be said that it can be used immediately. This is a relatively long -term plan. Through further lunar exploration, more information may be obtained. Maybe you will change the technical route in the future, orUse the updated technical path to build a moon base, "Ding Lieyun said.(Yang Jiafeng, chief reporter of the Yangtze River Daily)

【Edit: Wang Yujin】

For more exciting content, please download the "Da Wuhan" client in the major application markets.

- END -

In the early morning, more than a thousand boxes of beverages were scattered at the intersection!A group of people surrounded ...

Early morning on June 20A intersection in Siyang, SuqianAn accident occurred in a ...

Gold price, fall!Golden bars, buy and buy!what's the situation?

The international gold price hit a high of 2070.42 US dollars per ounce in March t...