iPhone14 is produced in advance in India, and the manufacturing industry must have a sense of crisis

Author:Wang Xinxi Time:2022.09.27

A few days ago, the news of India's plan to produce iPhone14 in India has aroused the industry's attention and heated discussion.

Some analysts said that by the end of 2022, 5%of iPhone 14 production will be transferred to India by Apple, and India will become the second largest smartphone market in China.

In a sense, the iPhone14 is expected to be produced in India in advance, which may be Cook's supply chain transfer to check the Chinese market.

Where is the iPhone produced? Where is Apple's strategic focus?

In fact, Apple's heavy soldiers in the Indian market and the production of iPhone in India have actually planned for many years. As early as 2017, Apple's iPhone SE smartphone was first produced in India. In September 2020, Apple also launched an Indian online store and opened the Apple Store retail store in India.

According to the current news, Apple has begun to produce the newly launched iPhone 14 series smartphones in India this year. At this time, it was only officially released for less than three weeks before the iPhone 14 series was officially released. In the past, it was usually produced in India after the new generation of iPhone was released for 6-9 months.

In other words, this signal of the iPhone14 series shows that Apple's production layout in India is improving. It is reported that more than 25%of the iPhone in 2025 will be manufactured in India. In addition, there are 20%iPad and Apple watches, 5%MacBook and 65%AirPods will be manufactured in Vietnam.

It is reported that India has already produced models including iPhone SE, iPhone 12/13. Tianfeng International Securities Analyst Guo Mingzheng said on September 1 that the mass production progress of iPhone 14 in India this year is still about 6 weeks later than China, but the gap has been significantly reduced. Therefore, it can be reasonably expected that India and China will be able to produce new iPhone 15 at the same time next year.

This means that Apple wants to make India's supply chain a supply chain market that is balanced with China. Of course, there is an important reason behind this that India levies huge taxes on imported goods, forcing Apple to build factories in India in India. In the past, domestic mobile phones built factories in India. At present, Apple is increasingly aware of the importance of the diversification of the supply chain.

India's population divide

Apple has been very cautious in the Indian market in the past years and has not been able to open the Indian market. India's localized manufacturing production efficiency is still hugely different from that of industrial workers and the overall level of manufacturing compared with China. Apple has increasingly higher requirements for manufacturing technology, capital scale, production efficiency, and quality. Foxconn rushed to set up factories in India, in terms of product quality and production efficiency, supply chain support, skilled industrial workers, and mechanization of mechanization, they will encounter certain certainty in terms of certain industrial workers and mechanization. Dilemma.

However, India's demographic dividend and market are the market that Apple has always wanted to win but has never been overcome, but from today's global market structure, India may not be able to open a market that can open the iPhone market incremental.

In particular, India's current population growth rate is still very fast. It is moving towards the world's first population country. The population that surpasses China may be a matter of time. This is very rare in the world, especially the high -end mobile phone market in India is growing rapidly. According to data, sales in 2021 have increased by 90%year -on -year compared with 2020. If Apple can open India's market space like Samsung, Xiaomi, and even OV, the sales potential of Apple's sales is inevitable.

Therefore, at the moment of the slowdown of global electronic products sales today, Apple has no reason to let go of the Indian market. It has a full reason to find ways to open the Indian market. A road that does not take.

Domestic mobile phones have been cultivating for many years, and Indian local manufacturing clusters are moving towards perfecting

In fact, Cook, as a supply chain trend, has been seeking a strategy of security and balance of supply chain.

In essence, Apple has been seeking its own sense of security, so as not to let any supply chain environment an irreplaceable position on itself, and threatens the bargaining power to Apple. From now on, this dual supplier strategy of Apple has also given the opportunity to grow and grow up in many domestic manufacturers. Of course, this is also an opportunity for China's manufacturing industry to use Apple to transform and upgrade.

Therefore, for Apple to transfer the supply chain to India, the manufacturing industry in China needs a certain sense of crisis. In the past, the Indian mobile phone market was defeated in the technology and product quality in the competition with domestic mobile phones. For foundry industry clusters, many Indian local manufacturers, such as Micromax, rely on Shenzhen foundries to assemble and sell in India, but with the development of the Indian local industrial chain, Indian mobile phone foundry and manufacturing are gradually developing.

Of course, the development of Indian local mobile phone manufacturing industry chain clusters is also indispensable for domestic manufacturers such as Xiaomi and OV. From the perspective of domestic mobile phone manufacturers, almost all Chinese mobile phone manufacturers have set up factories in India. Vivo, OPPO, Xiaomi, Gionee, Li Li Wait, in the past, they all invested in the construction of factories in India, and the construction of supporting the mobile phone supply chain has all landed in India. This has made a certain contribution and promotion role in promoting the improvement of the Indian mobile phone supply chain cluster. From the perspective of manufacturers, they have formed a pattern of heavy assets in the Indian market. Data show that Xiaomi currently has 7 factories in India and has contributed more than 20,000 jobs to India. Vivo built in India twice in India in 2015 and 2018, respectively. Smartphones sold in India 100%were made by India. At the beginning of this year, Vivo also announced its investment in 3 billion yuan in India, increasing the annual production capacity of Indian smartphones from 60 million to 120 million units.

Therefore, Apple's further development of production in India at this time has also been improved from India's manufacturing foundation. In addition, Apple has also seen that the consumption needs of electronic products in the Chinese market are entering the bottleneck. Therefore, Apple also also. Need to find an incremental market. The core driving factor of the transfer of the mobile phone manufacturing industry chain is business and consumer demand drive.

In other words, China's smartphone market has been saturated, the incremental space is not large, and the demand for changing machines has slowed down, but there is still a huge demographic dividend in the Indian market. For a mobile phone manufacturer, where does its production factory fall?

Chinese manufacturing must have a sense of crisis

Domestic needs to realize that a reality is that my country's manufacturing industry's proportion in GDP has been gradually declining. From 2011 to 2020, it has been falling. Since then, it has fallen from 32.45%in 2016 to 26.18%in 2020 Essence It took only 27.4%in 2021.

For the domestic mobile phone manufacturing industry, what needs to be considered is to promote the upgrade of high -standard technology upstream through technology upgrades, forming deeper cooperation, penetration and technology sharing with domestic mobile phone manufacturers, forming a win -win ecology, based on China's digital transformation of digital transformation Opportunities, continuously improve the quality and standards of supply chain production, drive the entire supply chain innovation, float upstream, and form irreplaceable technical competitive advantages.

From the past, the increase in domestic manufacturers' R & D investment has promoted the birth of new supply chain technology. Many "black technology" that many Apple has not yet adopted is now rapidly popular on Android phones. This is the upgrade of the entire mobile phone manufacturing industry chain chain. Transformation.

Because if Indian manufacturing cannot replace Made in the technical link, manufacturers such as Apple and other manufacturers need to return to China sooner or later. However, this may be the most ideal result. The worst result is that India may gradually eat China's manufacturing orders, and more manufacturing factories have gradually migrated India and Vietnam. India's "Business Standards" stated that India will develop a stronger ecosystem in the relevant manufacturing field in the next few years and position themselves as "the next China".

Of course, we often hold a joke and look down on India. They believe that India does not have this strength, but what needs to be known is that in the past, Western countries and Japan and South Korea also regarded China like this. We should not be too vigilant for the threat of India, but we should not be too lightweight.

After all, from the rise in the proportion of iPhone in India and early trends, India may transfer some of China's mobile phone manufacturing industry chains to India in the next few years. What impact will this bring?

In my opinion, this may drive India's mobile phone manufacturing industry chain cluster. This mobile phone manufacturing industry chain cluster has experienced in China in the past. Because foundry manufacturers need to rely on complicated supplier industrial facilities to produce, demand, environment, and industrial ecology are very dense. As a result, India's mobile phone production and assembly and research and development capabilities have been strengthened, which in turn may lead to weakening the competitiveness of China's mobile phone manufacturing industry.

Although a consensus is that India's manufacturing level is continuously improved, there is still a long way to go to copy China's success. However, China's mobile phone supply chain and even China's manufacturing industry must think. In the future, will this irreplaceable status in China continue to exist? Will the transfer of large factories weaken the competitiveness of the local supply chain? In other words, when the Apple supply chain shows signs of abroad, can China's local supply chain survive and make up for the vacancy of its business line loss and the employment market?

If the relatively low -cost market demand is concerned, the domestic lack of labor cost advantages and the lack of dominant advantages at the upstream technology level, then there may be more outstanding manufacturing entity manufacturers in the future to more bonus countries.

How to maintain its own competitiveness advantage, China's manufacturing industry needs a sense of crisis. Apple transferred the supply chain to India, which is a strategic transfer to check the Chinese supply chain. Competition is worthy of our reflection.

Author: Wang Xinxi TMT senior commentator.

- END -

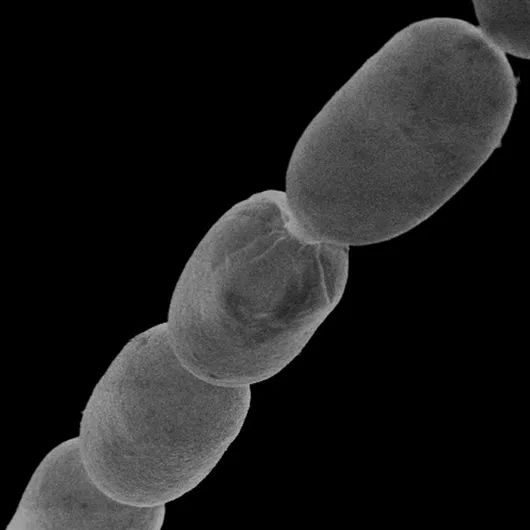

maximum!Is 1 cm bacteria called "microorganism"?

Text | XinyuIn the mangroves in the island of Laulipipu in Caribbean, some peculiar...

As we all know, bubbles can not only play play, but also ... | Play seriously

Everyone has played with bubblesBut the bubbles are very fragile in the impression...